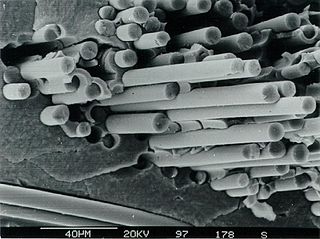

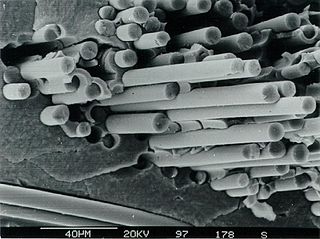

Carbon fibers or carbon fibres are fibers about 5 to 10 micrometers (0.00020–0.00039 in) in diameter and composed mostly of carbon atoms. Carbon fibers have several advantages: high stiffness, high tensile strength, high strength to weight ratio, high chemical resistance, high-temperature tolerance, and low thermal expansion. These properties have made carbon fiber very popular in aerospace, civil engineering, military, motorsports, and other competition sports. However, they are relatively expensive compared to similar fibers, such as glass fiber, basalt fibers, or plastic fibers.

A thermoplastic, or thermosoftening plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

Vectran is a manufactured fiber, spun from a liquid-crystal polymer (LCP) created by Celanese Corporation and now manufactured by Kuraray. Chemically it is an aromatic polyester produced by the polycondensation of 4-hydroxybenzoic acid and 6-hydroxynaphthalene-2-carboxylic acid.

Microfibre is synthetic fibre finer than one denier or decitex/thread, having a diameter of less than ten micrometers.

Lamination is the technique/process of manufacturing a material in multiple layers, so that the composite material achieves improved strength, stability, sound insulation, appearance, or other properties from the use of the differing materials, such as plastic. A laminate is a layered object or material assembled using heat, pressure, welding, or adhesives. Various coating machines, machine presses and calendering equipment are used.

Tyvek is a brand of synthetic flashspun high-density polyethylene fibers. The name "Tyvek" is a registered trademark of the American multinational chemical company DuPont, which discovered and commercialized Tyvek in the late 1950s and early 1960s.

Metallic fibers are manufactured fibers composed of metal, metallic alloys, plastic-coated metal, metal-coated plastic, or a core completely covered by metal.

A phase-change material (PCM) is a substance which releases/absorbs sufficient energy at phase transition to provide useful heat or cooling. Generally the transition will be from one of the first two fundamental states of matter - solid and liquid - to the other. The phase transition may also be between non-classical states of matter, such as the conformity of crystals, where the material goes from conforming to one crystalline structure to conforming to another, which may be a higher or lower energy state.

Thinsulate is a brand of synthetic fiber thermal insulation used in clothing. The word is a portmanteau of the words thin and insulate, trademarked by 3M. The material is made by the 3M Corporation and was first sold in 1979. It was originally marketed as an inexpensive alternative to down; at the time, 3M claimed it was twice as warm as an equivalent amount of any natural material.

Polyester is a category of polymers that contain the ester functional group in every repeat unit of their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include naturally occurring chemicals, such as in plants and insects, as well as synthetics such as polybutyrate. Natural polyesters and a few synthetic ones are biodegradable, but most synthetic polyesters are not. Synthetic polyesters are used extensively in clothing.

Nonwoven fabric or non-woven fabric is a fabric-like material made from staple fibre (short) and long fibres, bonded together by chemical, mechanical, heat or solvent treatment. The term is used in the textile manufacturing industry to denote fabrics, such as felt, which are neither woven nor knitted. Some non-woven materials lack sufficient strength unless densified or reinforced by a backing. In recent years, non-wovens have become an alternative to polyurethane foam.

Ceramic engineering is the science and technology of creating objects from inorganic, non-metallic materials. This is done either by the action of heat, or at lower temperatures using precipitation reactions from high-purity chemical solutions. The term includes the purification of raw materials, the study and production of the chemical compounds concerned, their formation into components and the study of their structure, composition and properties.

Olefin fiber is a synthetic fiber made from a polyolefin, such as polypropylene or polyethylene. It is used in wallpaper, carpeting, ropes, and vehicle interiors.

"Technical textile" refers to a category of textiles specifically engineered and manufactured to serve functional purposes beyond traditional apparel and home furnishing applications. These textiles are designed with specific performance characteristics and properties, making them suitable for various industrial, medical, automotive, aerospace, and other technical applications. Unlike conventional textiles used for clothing or decoration, technical textiles are optimized to offer qualities such as strength, durability, flame resistance, chemical resistance, moisture management, and other specialized functionalities to meet the specific needs of diverse industries and sectors.

PrimaLoft® is a brand of patented synthetic microfiber thermal insulation material that was developed for the United States Army in the 1980s. PrimaLoft is a registered trademark of PrimaLoft, Inc., the brand's parent company.

In textile manufacturing, finishing refers to the processes that convert the woven or knitted cloth into a usable material and more specifically to any process performed after dyeing the yarn or fabric to improve the look, performance, or "hand" (feel) of the finish textile or clothing. The precise meaning depends on context.

In materials science ceramic matrix composites (CMCs) are a subgroup of composite materials and a subgroup of ceramics. They consist of ceramic fibers embedded in a ceramic matrix. The fibers and the matrix both can consist of any ceramic material, including carbon and carbon fibers.

Aircraft fabric covering is a term used for both the material used and the process of covering aircraft open structures. It is also used for reinforcing closed plywood structures. The de Havilland Mosquito is an example of this technique, as are the pioneering all-wood monocoque fuselages of certain World War I German aircraft like the LFG Roland C.II in its wrapped Wickelrumpf plywood strip and fabric covering.

Textile performance, also known as fitness for purpose, is a textile's capacity to withstand various conditions, environments, and hazards, qualifying it for particular uses. The performance of textile products influences their appearance, comfort, durability, and protection. Different textile applications require a different set of performance parameters. As a result, the specifications determine the level of performance of a textile product. Textile testing certifies the product's conformity to buying specification. It describes product manufactured for non-aesthetic purposes, where fitness for purpose is the primary criterion. Engineering of high-performance fabrics presents a unique set of challenges.