In metalworking and jewelry making, casting is a process in which a liquid metal is delivered into a mold that contains a negative impression of the intended shape. The metal is poured into the mold through a hollow channel called a sprue. The metal and mold are then cooled, and the metal part is extracted. Casting is most often used for making complex shapes that would be difficult or uneconomical to make by other methods.

In printing, type metal refers to the metal alloys used in traditional typefounding and hot metal typesetting. Historically, type metal was an alloy of lead, tin and antimony in different proportions depending on the application, be it individual character mechanical casting for hand setting, mechanical line casting or individual character mechanical typesetting and stereo plate casting. The proportions used are in the range: lead 50‒86%, antimony 11‒30% and tin 3‒20%. Antimony and tin are added to lead for durability while reducing the difference between the coefficients of expansion of the matrix and the alloy. Apart from durability, the general requirements for type-metal are that it should produce a true and sharp cast, and retain correct dimensions and form after cooling down. It should also be easy to cast, at reasonable low melting temperature, iron should not dissolve in the molten metal, and mould and nozzles should stay clean and easy to maintain. Today, Monotype machines can utilize a wide range of different alloys. Mechanical linecasting equipment uses alloys that are close to eutectic.

An ingot is a piece of relatively pure material, usually metal, that is cast into a shape suitable for further processing. In steelmaking, it is the first step among semi-finished casting products. Ingots usually require a second procedure of shaping, such as cold/hot working, cutting, or milling to produce a useful final product. Non-metallic and semiconductor materials prepared in bulk form may also be referred to as ingots, particularly when cast by mold based methods. Precious metal ingots can be used as currency, or as a currency reserve, as with gold bars.

An amorphous metal is a solid metallic material, usually an alloy, with disordered atomic-scale structure. Most metals are crystalline in their solid state, which means they have a highly ordered arrangement of atoms. Amorphous metals are non-crystalline, and have a glass-like structure. But unlike common glasses, such as window glass, which are typically electrical insulators, amorphous metals have good electrical conductivity and can show metallic luster.

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used.

Plasma arc welding (PAW) is an arc welding process similar to gas tungsten arc welding (GTAW). The electric arc is formed between an electrode and the workpiece. The key difference from GTAW is that in PAW, the electrode is positioned within the body of the torch, so the plasma arc is separated from the shielding gas envelope. The plasma is then forced through a fine-bore copper nozzle which constricts the arc and the plasma exits the orifice at high velocities and a temperature approaching 28,000 °C (50,000 °F) or higher.

Blow molding is a manufacturing process for forming hollow plastic parts. It is also used for forming glass bottles or other hollow shapes.

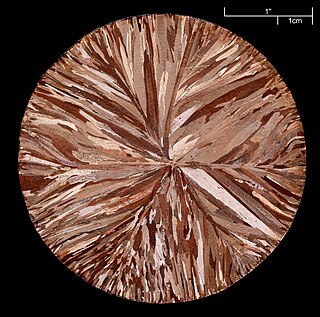

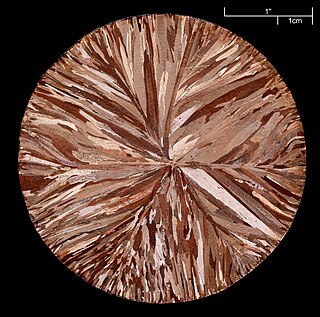

Spin casting, also known as centrifugal rubber mold casting (CRMC), is a method of utilizing inertia to produce castings from a rubber mold. Typically, a disc-shaped mold is spun along its central axis at a set speed. The casting material, usually molten metal or liquid thermoset plastic, is then poured in through an opening at the top-center of the mold. The filled mold then continues to spin as the metal solidifies.

A foundry is a factory that produces metal castings. Metals are cast into shapes by melting them into a liquid, pouring the metal into a mold, and removing the mold material after the metal has solidified as it cools. The most common metals processed are aluminum and cast iron. However, other metals, such as bronze, brass, steel, magnesium, and zinc, are also used to produce castings in foundries. In this process, parts of desired shapes and sizes can be formed.

Continuous casting, also called strand casting, is the process whereby molten metal is solidified into a "semifinished" billet, bloom, or slab for subsequent rolling in the finishing mills. Prior to the introduction of continuous casting in the 1950s, steel was poured into stationary molds to form ingots. Since then, "continuous casting" has evolved to achieve improved yield, quality, productivity and cost efficiency. It allows lower-cost production of metal sections with better quality, due to the inherently lower costs of continuous, standardised production of a product, as well as providing increased control over the process through automation. This process is used most frequently to cast steel. Aluminium and copper are also continuously cast.

Investment casting is an industrial process based on lost-wax casting, one of the oldest known metal-forming techniques. The term "lost-wax casting" can also refer to modern investment casting processes.

Spray forming, also known as spray casting, spray deposition and in-situ compaction, is a method of casting near net shape metal components with homogeneous microstructures via the deposition of semi-solid sprayed droplets onto a shaped substrate. In spray forming an alloy is melted, normally in an induction furnace, then the molten metal is slowly poured through a conical tundish into a small-bore ceramic nozzle. The molten metal exits the furnace as a thin free-falling stream and is broken up into droplets by an annular array of gas jets, and these droplets then proceed downwards, accelerated by the gas jets to impact onto a substrate. The process is arranged such that the droplets strike the substrate whilst in the semi-solid condition, this provides sufficient liquid fraction to 'stick' the solid fraction together. Deposition continues, gradually building up a spray formed billet of metal on the substrate.

Permanent mold casting is a metal casting process that employs reusable molds, usually made from metal. The most common process uses gravity to fill the mold, however gas pressure or a vacuum are also used. A variation on the typical gravity casting process, called slush casting, produces hollow castings. Common casting metals are aluminium, magnesium, and copper alloys. Other materials include tin, zinc, and lead alloys and iron and steel are also cast in graphite molds.

An amorphous brazing foil (ABF) is a form of eutectic amorphous metal that serves as a filler metal in brazing operations. ABFs are composed of various transition metals blended with metalloids like silicon, boron, and phosphorus. By precisely managing the concentration of these metalloids to achieve or approach the eutectic point, these alloys can undergo rapid solidification to form a ductile, amorphous foil. This process allows the ABF to effectively bond materials in the brazing process, providing a strong and seamless joint.

A casting defect is an undesired irregularity in a metal casting process. Some defects can be tolerated while others can be repaired, otherwise they must be eliminated. They are broken down into five main categories: gas porosity, shrinkage defects, mould material defects, pouring metal defects, and metallurgical defects.

Centrifugal casting or rotocasting is a casting technique that is typically used to cast thin-walled cylinders. It is typically used to cast materials such as metals, glass, and concrete. A high quality is attainable by control of metallurgy and crystal structure. Unlike most other casting techniques, centrifugal casting is chiefly used to manufacture rotationally symmetric stock materials in standard sizes for further machining, rather than shaped parts tailored to a particular end-use.

Corium, also called fuel-containing material (FCM) or lava-like fuel-containing material (LFCM), is a material that is created in a nuclear reactor core during a nuclear meltdown accident. Resembling lava in consistency, it consists of a mixture of nuclear fuel, fission products, control rods, structural materials from the affected parts of the reactor, products of their chemical reaction with air, water, steam, and in the event that the reactor vessel is breached, molten concrete from the floor of the reactor room.

Splat quenching is a metallurgical, metal morphing technique used for forming metals with a particular crystal structure by means of extremely rapid quenching, or cooling.

Cymat Technologies is an innovative materials technology company based out of Mississauga, Ontario, Canada, and one of the world leaders in the production of stabilized aluminum foam.

A die in polymer processing is a metal restrictor or channel capable of providing a constant cross sectional profile to a stream of liquid polymer. This allows for continuous processing of shapes such as sheets, films, pipes, rods, and other more complex profiles. This is a continuous process, allowing for constant production, as opposed to a sequential (non-constant) process such as injection molding.