An amorphous metal transformer (AMT) is a type of energy efficient transformer found on electric grids. [1] The magnetic core of this transformer is made with a ferromagnetic amorphous metal. The typical material (Metglas) is an alloy of iron with boron, silicon, and phosphorus in the form of thin (e.g. 25 µm) foils rapidly cooled from melt. These materials have high magnetic susceptibility, very low coercivity and high electrical resistance. The high resistance and thin foils lead to low losses by eddy currents when subjected to alternating magnetic fields. On the downside amorphous alloys have a lower saturation induction and often a higher magnetostriction compared to conventional crystalline iron-silicon electrical steel. [2]

In a transformer the no-load loss is dominated by the core loss. With an amorphous core, this can be 70–80% lower than with traditional crystalline materials[ citation needed ]. The loss under heavy load is dominated by the resistance of the copper windings and thus called copper loss. Here the lower saturation magnetization of amorphous cores tends to result in a lower efficiency at full load. Using more copper and core material it is possible to compensate for this. So high efficiency AMTs can be more efficient at low and high load, though at a larger size. The more expensive amorphous core material, the more difficult handling and the need for more copper windings make an AMT more expensive than a traditional transformer[ citation needed ].

The main application of AMTs are the grid distribution transformers rated at about 50–1000 kVA. These transformers typically run 24 hours a day and at a low load factor (average load divided by nominal load). The no load loss of these transformers makes up a significant part of the loss of the whole distribution net. Amorphous iron is also used in specialized electric motors that operate at high frequencies of perhaps 350 Hz or more. [3]

More efficient transformers lead to a reduction of generation requirement and, when using electric power generated from fossil fuels, less CO2 emissions. This technology has been widely adopted by large developing countries such as China [4] and India [5] where labour cost is low. AMT are in fact more labour-intensive than conventional distribution transformers, a reason that explains a very low adoption in the comparable (by size) European market. These two countries can potentially save 25–30 TWh electricity annually, eliminate 6-8 GW generation investment, and reduce 20–30 million tons of CO2 emission by fully utilizing this technology. [6]

An inductor, also called a coil, choke, or reactor, is a passive two-terminal electrical component that stores energy in a magnetic field when electric current flows through it. An inductor typically consists of an insulated wire wound into a coil.

A metal is a material that, when freshly prepared, polished, or fractured, shows a lustrous appearance, and conducts electricity and heat relatively well. Metals are typically ductile and malleable. These properties are the result of the metallic bond between the atoms or molecules of the metal.

Mu-metal is a nickel–iron soft ferromagnetic alloy with very high permeability, which is used for shielding sensitive electronic equipment against static or low-frequency magnetic fields. It has several compositions. One such composition is approximately 77% nickel, 16% iron, 5% copper, and 2% chromium or molybdenum. More recently, mu-metal is considered to be ASTM A753 Alloy 4 and is composed of approximately 80% nickel, 5% molybdenum, small amounts of various other elements such as silicon, and the remaining 12 to 15% iron. The name came from the Greek letter mu (μ) which represents permeability in physics and engineering formulas. A number of different proprietary formulations of the alloy are sold under trade names such as MuMETAL, Mumetall, and Mumetal2.

A transformer is a passive component that transfers electrical energy from one electrical circuit to another circuit, or multiple circuits. A varying current in any coil of the transformer produces a varying magnetic flux in the transformer's core, which induces a varying electromotive force across any other coils wound around the same core. Electrical energy can be transferred between separate coils without a metallic (conductive) connection between the two circuits. Faraday's law of induction, discovered in 1831, describes the induced voltage effect in any coil due to a changing magnetic flux encircled by the coil.

Alternating current (AC) is an electric current which periodically reverses direction and changes its magnitude continuously with time in contrast to direct current (DC) which flows only in one direction. Alternating current is the form in which electric power is delivered to businesses and residences, and it is the form of electrical energy that consumers typically use when they plug kitchen appliances, televisions, fans and electric lamps into a wall socket. A common source of DC power is a battery cell in a flashlight. The abbreviations AC and DC are often used to mean simply alternating and direct, as when they modify current or voltage.

An electromagnet is a type of magnet in which the magnetic field is produced by an electric current. Electromagnets usually consist of wire wound into a coil. A current through the wire creates a magnetic field which is concentrated in the hole, denoting the center of the coil. The magnetic field disappears when the current is turned off. The wire turns are often wound around a magnetic core made from a ferromagnetic or ferrimagnetic material such as iron; the magnetic core concentrates the magnetic flux and makes a more powerful magnet.

An amorphous metal is a solid metallic material, usually an alloy, with disordered atomic-scale structure. Most metals are crystalline in their solid state, which means they have a highly ordered arrangement of atoms. Amorphous metals are non-crystalline, and have a glass-like structure. But unlike common glasses, such as window glass, which are typically electrical insulators, amorphous metals have good electrical conductivity and can show metallic luster.

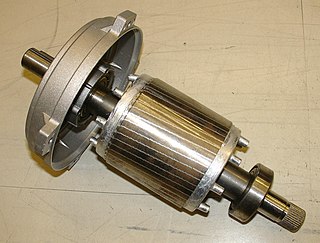

A squirrel-cage rotor is the rotating part of the common squirrel-cage induction motor. It consists of a cylinder of steel laminations, with aluminum or copper conductors embedded in its surface. In operation, the non-rotating stator winding is connected to an alternating current power source; the alternating current in the stator produces a rotating magnetic field. The rotor winding has current induced in it by the stator field, like a transformer except that the current in the rotor is varying at the stator field rotation rate minus the physical rotation rate. The interaction of the magnetic fields of currents in the stator and rotor produce a torque on the rotor.

A distribution transformer or service transformer is a transformer that provides the final voltage transformation in the electric power distribution system, stepping down the voltage used in the distribution lines to the level used by the customer. The invention of a practical efficient transformer made AC power distribution feasible; a system using distribution transformers was demonstrated as early as 1882.

A magnetic core is a piece of magnetic material with a high magnetic permeability used to confine and guide magnetic fields in electrical, electromechanical and magnetic devices such as electromagnets, transformers, electric motors, generators, inductors, magnetic recording heads, and magnetic assemblies. It is made of ferromagnetic metal such as iron, or ferrimagnetic compounds such as ferrites. The high permeability, relative to the surrounding air, causes the magnetic field lines to be concentrated in the core material. The magnetic field is often created by a current-carrying coil of wire around the core.

Inrush current, input surge current, or switch-on surge is the maximal instantaneous input current drawn by an electrical device when first turned on. Alternating-current electric motors and transformers may draw several times their normal full-load current when first energized, for a few cycles of the input waveform. Power converters also often have inrush currents much higher than their steady-state currents, due to the charging current of the input capacitance. The selection of over-current-protection devices such as fuses and circuit breakers is made more complicated when high inrush currents must be tolerated. The over-current protection must react quickly to overload or short-circuit faults but must not interrupt the circuit when the inrush current flows.

Seen in some magnetic materials, saturation is the state reached when an increase in applied external magnetic field H cannot increase the magnetization of the material further, so the total magnetic flux density B more or less levels off. Saturation is a characteristic of ferromagnetic and ferrimagnetic materials, such as iron, nickel, cobalt and their alloys. Different ferromagnetic materials have different saturation levels.

A ferrite is a ceramic material made by mixing and firing large proportions of iron(III) oxide (Fe2O3, rust) blended with small proportions of one or more additional metallic elements, such as strontium, barium, manganese, nickel, and zinc. They are ferrimagnetic, meaning they can be magnetized or attracted to a magnet. Unlike other ferromagnetic materials, most ferrites are not electrically conductive, making them useful in applications like magnetic cores for transformers to suppress eddy currents. Ferrites can be divided into two families based on their resistance to being demagnetized (magnetic coercivity).

Electrical steel is an iron alloy tailored to produce specific magnetic properties: small hysteresis area resulting in low power loss per cycle, low core loss, and high permeability.

Magnet wire or enameled wire is a copper (Cu) or aluminium (Al) wire coated with a very thin layer of insulation. It is used in the construction of transformers, inductors, motors, generators, speakers, hard disk head actuators, electromagnets, electric guitar pickups and other applications that require tight coils of insulated wire.

In electronics, a ferrite core is a type of magnetic core made of ferrite on which the windings of electric transformers and other wound components such as inductors are formed. It is used for its properties of high magnetic permeability coupled with low electrical conductivity. Because of their comparatively low losses at high frequencies, they are extensively used in the cores of RF transformers and inductors in applications such as switched-mode power supplies, and ferrite loopstick antennas for AM radio receivers.

Permendur is a cobalt-iron soft ferromagnetic alloy with equal parts of cobalt and iron which is notable for its high magnetic saturation level. Its saturation flux density of around 2.4 tesla is the highest of any commercially available metal. Coupled with its low coercivity and core losses, its high saturation and permeability makes Permendur useful as magnetic cores in transformers, electric generators and other electrical equipment. The advantage of high saturation in a magnetic core is that it can function at higher magnetic field strengths, so the core can be smaller and lighter for a given magnetic flux and power level. Permendur is used for magnetic cores and pole pieces in lightweight transformers and electric motors used in aircraft. The alloy was invented in 1929 by Gustav Elmen at Bell Telephone Laboratories. Various formulations are sold under different trade names.

A variety of types of electrical transformer are made for different purposes. Despite their design differences, the various types employ the same basic principle as discovered in 1831 by Michael Faraday, and share several key functional parts.

In a typical power distribution grid, electric transformer power loss typically contributes to about 40-50% of the total transmission and distribution loss. Energy efficient transformers are therefore an important means to reduce transmission and distribution loss. With the improvement of electrical steel properties, the losses of a transformer in 2010 can be half that of a similar transformer in the 1970s. With new magnetic materials, it is possible to achieve even higher efficiency. The amorphous metal transformer is a modern example.

Splat quenching is a metallurgical, metal morphing technique used for forming metals with a particular crystal structure by means of extremely rapid quenching, or cooling.