Flow measurement is the quantification of bulk fluid movement. Flow can be measured using devices called flowmeters in various ways. The common types of flowmeters with industrial applications are listed below:

Rebar, known when massed as reinforcing steel or steel reinforcement, is a tension device added to concrete to form reinforced concrete and reinforced masonry structures to strengthen and aid the concrete under tension. Concrete is strong under compression, but has low tensile strength. Rebar usually consists of steel bars which significantly increase the tensile strength of the structure. Rebar surfaces feature a continuous series of ribs, lugs or indentations to promote a better bond with the concrete and reduce the risk of slippage.

A screw cap or closure is a common type of closure for bottles, jars, and tubes.

A fish ladder, also known as a fishway, fish pass, fish steps, or fish cannon, is a structure on or around artificial and natural barriers to facilitate diadromous fishes' natural migration as well as movements of potamodromous species. Most fishways enable fish to pass around the barriers by swimming and leaping up a series of relatively low steps into the waters on the other side. The velocity of water falling over the steps has to be great enough to attract the fish to the ladder, but it cannot be so great that it washes fish back downstream or exhausts them to the point of inability to continue their journey upriver.

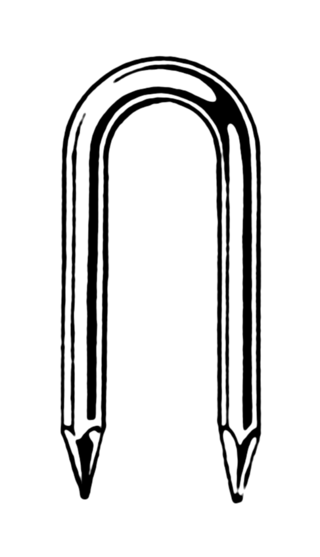

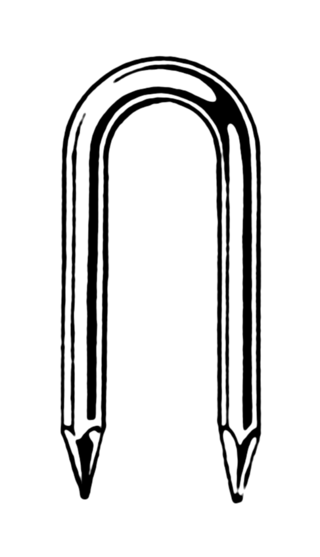

A staple is a type of two-pronged fastener, usually metal, used for joining, gathering, or binding materials together. Large staples might be used with a hammer or staple gun for masonry, roofing, corrugated boxes and other heavy-duty uses. Smaller staples are used with a stapler to attach pieces of paper together; such staples are a more permanent and durable fastener for paper documents than the paper clip.

A manhole is an opening to a confined space such as a shaft, utility vault, or large vessel. Manholes, typically protected by a manhole cover, are often used as an access point for an underground public utility, allowing inspection, maintenance, and system upgrades. The majority of underground services have manholes, including water, sewers, telephone, electricity, storm drains, district heating, and gas.

Ready-mix concrete (RMC) is concrete that is manufactured in a batch plant, according to each specific job requirement, then delivered to the job site "ready to use".

Sound Transmission Class is an integer rating of how well a building partition attenuates airborne sound. In the US, it is widely used to rate interior partitions, ceilings, floors, doors, windows and exterior wall configurations. Outside the US, the ISO Sound Reduction Index (SRI) is used. The STC rating very roughly reflects the decibel reduction of noise that a partition can provide. The STC is useful for evaluating annoyance due to speech sounds, but not music or machinery noise as these sources contain more low frequency energy than speech.

Precast concrete is a construction product produced by casting concrete in a reusable mold or "form" which is then cured in a controlled environment, transported to the construction site and maneuvered into place; examples include precast beams, and wall panels, floors, roofs, and piles. In contrast, cast-in-place concrete is poured into site-specific forms and cured on site.

An asphalt shingle is a type of wall or roof shingle that uses asphalt for waterproofing. It is one of the most widely used roofing covers in North America because it has a relatively inexpensive up-front cost and is fairly simple to install.

Cast stone or reconstructed stone is a highly refined building material, a form of precast concrete used as masonry intended to simulate natural-cut stone. It is used for architectural features: trim, or ornament; facing buildings or other structures; statuary; and for garden ornaments. Cast stone can be made from white and/or grey cements, manufactured or natural sands, crushed stone or natural gravels, and colored with mineral coloring pigments. Cast stone may replace such common natural building stones as limestone, brownstone, sandstone, bluestone, granite, slate, coral, and travertine.

A grease trap is a plumbing device designed to intercept most greases and solids before they enter a wastewater disposal system. Common wastewater contains small amounts of oils which enter into septic tanks and treatment facilities to form a floating scum layer. This scum layer is very slowly digested and broken down by microorganisms in the anaerobic digestion process. Large amounts of oil from food preparation in restaurants can overwhelm a septic tank or treatment facility, causing the release of untreated sewage into the environment. High-viscosity fats and cooking grease such as lard solidify when cooled, and can combine with other disposed solids to block drain pipes.

Log flumes are amusement rides consisting of a water flume and (artificial) hollow logs or boats. Passengers sit in the logs, which are propelled along the flume by the flow of water.

The concrete slump test measures the consistency of fresh concrete before it sets. It is performed to check the workability of freshly made concrete, and therefore the ease with which concrete flows. It can also be used as an indicator of an improperly mixed batch. The test is popular due to the simplicity of apparatus used and simple procedure. The slump test is used to ensure uniformity for different loads of concrete under field conditions.

Nass Corporation B.S.C. is a Bahraini public joint-stock company established and listed on the Bahrain Stock Exchange since the year 2005. The paid-up capital is currently BHD 22 million.

The Parshall flume is an open channel flow-metering device that was developed to measure the flow of surface water and irrigation flow. The Parshall flume is a modified version of the Venturi flume. Named after its creator, Dr. Ralph L. Parshall of the U.S. Soil Conservation Service, the Parshall flume is a fixed hydraulic structure used in measuring volumetric flow rate in surface water, industrial discharges, municipal sewer lines, and influent/effluent flows in wastewater treatment plants. The Parshall flume accelerates the flow by contracting both the parallel sidewalls and a drop in the floor at the flume throat. Under free-flow conditions, the depth of water at a specified location upstream of the flume throat can be converted to a rate of flow. Some states specify the use of Parshall flumes, by law, for certain situations. Differences between the Venturi and Parshall flume include reduction of the inlet converging angle, lengthening the throat section, reduction of the discharge divergence angle, and introducing a drop through the throat.

The Cutthroat flume is a class of flow measurement flume developed during 1966/1967 that is used to measure the flow of surface waters, sewage flows, and industrial discharges. Like other flumes, the Cutthroat flume is a fixed hydraulic structure. Using vertical sidewalls throughout, the flume accelerates flow through a contraction of sidewalls until the flow reaches the "throat" of the flume, where the flow is then expanded. Unlike the Parshall flume, the Cutthroat flume lacks a parallel-walled throat section and maintains a flat floor throughout the flume.

A Montana flume is a popular modification of the standard Parshall flume. The Montana flume removes the throat and discharge sections of the Parshall flume, resulting a flume that is lighter in weight, shorter in length, and less costly to manufacture. Montana flumes are used to measure surface waters, irrigations flows, industrial discharges, and wastewater treatment plant flows.

The Palmer-Bowlus flume, is a class of flumes commonly used to measure the flow of wastewater in sewer pipes and conduits. The Palmer-Bowlus flume has a u-shaped cross-section and was designed to be inserted into, or in line with, pipes and u-channels found in sanitary sewer applications.

A sanitary manhole is a manhole that is used as an access point for maintenance and inspection of an underground sanitary sewer system. Sanitary manholes are sometimes used as vents to prevent the buildup of pressurized sewage gas. Additionally, they are used for debris removal, and application of chemicals such as degreaser and insecticide.