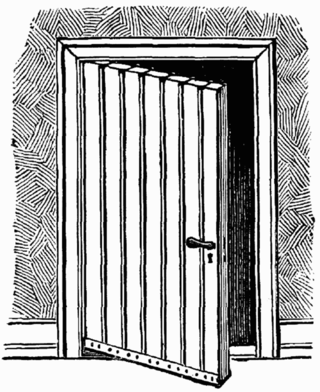

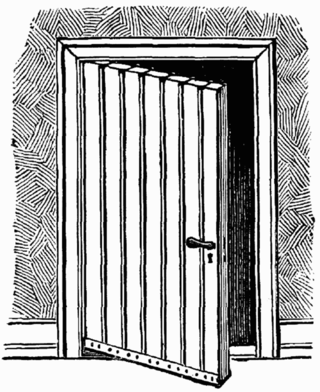

A door is a hinged or otherwise movable barrier that allows ingress (entry) into and egress (exit) from an enclosure. The created opening in the wall is a doorway or portal. A door's essential and primary purpose is to provide security by controlling access to the doorway (portal). Conventionally, it is a panel that fits into the doorway of a building, room, or vehicle. Doors are generally made of a material suited to the door's task. They are commonly attached by hinges, but can move by other means, such as slides or counterbalancing.

Lumber is wood that has been processed into uniform and useful sizes, including beams and planks or boards. Lumber is mainly used for construction framing, as well as finishing. Lumber has many uses beyond home building. Lumber is referred to as timber in the United Kingdom, Europe, Australia, and New Zealand, while in other parts of the world the term timber refers specifically to unprocessed wood fiber, such as cut logs or standing trees that have yet to be cut.

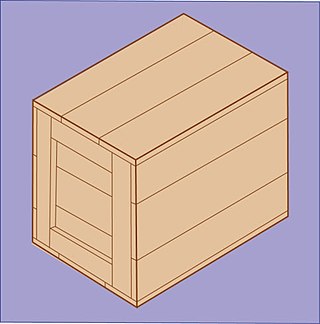

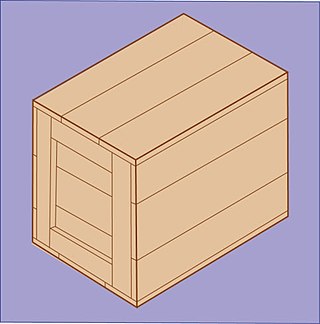

A box is a container with rigid sides used for the storage or transportation of its contents. Most boxes have flat, parallel, rectangular sides. Boxes can be very small or very large and can be used for a variety of purposes, from functional to decorative.

Packaging is the science, art and technology of enclosing or protecting products for distribution, storage, sale, and use. Packaging also refers to the process of designing, evaluating, and producing packages. Packaging can be described as a coordinated system of preparing goods for transport, warehousing, logistics, sale, and end use. Packaging contains, protects, preserves, transports, informs, and sells. In many countries it is fully integrated into government, business, institutional, industrial, and for personal use.

Optical disc packaging is the packaging that accompanies CDs, DVDs, and other formats of optical discs. Most packaging is rigid or semi-rigid and designed to protect the media from scratches and other types of exposure damage.

A pallet is a flat transport structure, which supports goods in a stable fashion while being lifted by a forklift, a pallet jack, a front loader, a jacking device, or an erect crane. Many pallets can handle a load of 1,000 kg (2,200 lb). While most pallets are wooden, pallets can also be made of plastic, metal, paper, and recycled materials.

A crate is a large shipping container, often made of wood, typically used to transport or store large, heavy items. Steel and aluminium crates are also used. Specialized crates were designed for specific products, and were often made to be reusable, such as the "bottle crates" for milk and soft drinks.

Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and trimmed to create a usable product. The sheet, or "film" when referring to thinner gauges and certain material types, is heated in an oven to a high-enough temperature that permits it to be stretched into or onto a mold and cooled to a finished shape. Its simplified version is vacuum forming.

A distribution center for a set of products is a warehouse or other specialized building, often with refrigeration or air conditioning, which is stocked with products (goods) to be redistributed to retailers, to wholesalers, or directly to consumers. A distribution center is a principal part, the order processing element, of the entire order fulfillment process. Distribution centers are usually thought of as being demand driven. A distribution center can also be called a warehouse, a DC, a fulfillment center, a cross-dock facility, a bulk break center, and a package handling center. The name by which the distribution center is known is commonly based on the purpose of the operation. For example, a "retail distribution center" normally distributes goods to retail stores, an "order fulfillment center" commonly distributes goods directly to consumers, and a cross-dock facility stores little or no product but distributes goods to other destinations.

Strapping, also known as bundling and banding, is the process of applying a strap to an item to combine, stabilize, hold, reinforce, or fasten it. A strap may also be referred to as strapping. Strapping is most commonly used in the packaging industry.

Go equipment refers to the board, stones, and bowls for the stones required to play the game of Go. The quality and materials used in making Go equipment varies considerably, and the cost varies accordingly from economical to extremely expensive.

Intermediate bulk containers are industrial-grade containers engineered for the mass handling, transport, and storage of liquids, semi-solids, pastes, or solids. The two main categories of IBC tanks are flexible IBCs and rigid IBCs. Many IBCs are reused or repurposed.

Pallet rack is a material handling storage aid system designed to store materials on pallets. Although there are many varieties of pallet racking, all types allow for the storage of palletized materials in horizontal rows with multiple levels. Forklift trucks are usually required to place the loaded pallets onto the racks for storage. Since the Second World War, pallet racks have become a ubiquitous element of most modern warehouses, manufacturing facilities, retail centers, and other storage and distribution facilities. All types of pallet racking increase storage density of the stored goods. Costs associated with the racking increases with increasing storage density.

A bulk box, also known as a bulk bin, skid box, pallet box, bin box, gaylord, or octabin, is a pallet-size box used for storage and shipping of bulk or packaged goods. Bulk boxes can be designed to hold many different types of items such as plastic pellets, watermelons, electronic components, and even liquids; some bulk boxes are stackable.

The term unit load refers to the size of an assemblage into which a number of individual items are combined for ease of storage and handling, for example a pallet load represents a unit load which can be moved easily with a pallet jack or forklift truck, or a container load represents a unit for shipping purposes. A unit load can be packed tightly into a warehouse rack, intermodal container, truck or boxcars, yet can be easily broken apart at a distribution point, usually a distribution center, wholesaler, or retail store for sale to consumers or for use.

A wooden box is a container made of wood for storage or as a shipping container.

A shipping container is a container with strength suitable to withstand shipment, storage, and handling. Shipping containers range from large reusable steel boxes used for intermodal shipments to the ubiquitous corrugated boxes. In the context of international shipping trade, "container" or "shipping container" is virtually synonymous with "intermodal freight container", a container designed to be moved from one mode of transport to another without unloading and reloading.

Shelf-ready packaging (SRP) and retail-ready packaging (RRP) refers to the packaging of a product so that it is delivered to a retailer in packaging which is optimized for efficient stocking and sale.

The EUR-pallet, also known as Euro-pallet or EPAL-pallet, is the standard European pallet as specified by the UIC pallet working group and the UIC 435-2 leaflet. Pallets conforming to the standardization are eligible for the European Pallet Pool (EPP), the system which allows for an exchange as "pallet for pallet".

A Euro container, also called Eurobox, Euro crate or KLT box, is an industrial stacking container conforming to the VDA 4500 standard. The standard was originally defined by the German Association of the Automotive Industry (VDA) for the automotive industry, but was subsequently adopted across many other areas of manufacturing and the shipping industry. The most common sizes are 600 × 400 mm and 400 × 300 mm, which can be stacked together to fill a Euro-pallet measuring 1200 × 800 mm.