A serial number is a unique identifier used to uniquely identify an item, and is usually assigned incrementally or sequentially.

A prototype is an early sample, model, or release of a product built to test a concept or process. It is a term used in a variety of contexts, including semantics, design, electronics, and software programming. A prototype is generally used to evaluate a new design to enhance precision by system analysts and users. Prototyping serves to provide specifications for a real, working system rather than a theoretical one. Physical prototyping has a long history, and paper prototyping and virtual prototyping now extensively complement it. In some design workflow models, creating a prototype is the step between the formalization and the evaluation of an idea.

In marketing, a product is an object, or system, or service made available for consumer use as of the consumer demand; it is anything that can be offered to a market to satisfy the desire or need of a customer. In retailing, products are often referred to as merchandise, and in manufacturing, products are bought as raw materials and then sold as finished goods. A service is also regarded as a type of product.

This page is a glossary of library and information science.

A datasheet, data sheet, or spec sheet is a document that summarizes the performance and other characteristics of a product, machine, component, material, subsystem, or software in sufficient detail that allows a buyer to understand what the product is and a design engineer to understand the role of the component in the overall system. Typically, a datasheet is created by the manufacturer and begins with an introductory page describing the rest of the document, followed by listings of specific characteristics, with further information on the connectivity of the devices. In cases where there is relevant source code to include, it is usually attached near the end of the document or separated into another file. Datasheets are created, stored, and distributed via product information management or product data management systems.

A mobile data terminal (MDT) or mobile digital computer (MDC) is a computerized device used in emergency services, public transport, taxicabs, package delivery, roadside assistance, and logistics, among other fields, to communicate with a central dispatcher. They are also used to display mapping and information relevant to the tasks and actions performed by the vehicle such as CAD drawings, diagrams and safety information.

The presence of the logo on commercial products indicates that the manufacturer or importer affirms the goods' conformity with European health, safety, and environmental protection standards. It is not a quality indicator or a certification mark. The CE marking is required for goods sold in the European Economic Area (EEA); goods sold elsewhere may also carry the mark.

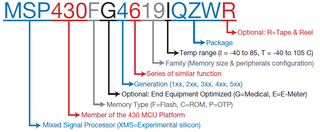

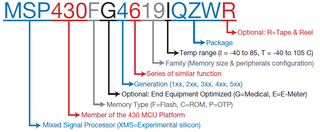

A part number is an identifier of a particular part design or material used in a particular industry. Its purpose is to simplify reference that item. A part number unambiguously identifies a part design within a single corporation, sometimes across several corporations. For example, when specifying a screw, it is easier to refer to "HSC0424PP" than saying "Hardware, screw, machine, 4-40, 3/4" long, pan head, Phillips". In this example, "HSC0424PP" is the part number. It may be prefixed in database fields as "PN HSC0424PP" or "P/N HSC0424PP". The "Part Number" term is often used loosely to refer to items or components, and it's equivalent to "Item Number", and overlaps with other terms like SKU.

A logbook is a record used to record states, events, or conditions applicable to complex machines or the personnel who operate them. Logbooks are commonly associated with the operation of aircraft, nuclear plants, particle accelerators, and ships.

Product information management (PIM) is the process of managing all the information required to market and sell products through distribution channels. This product data is created by an internal organization to support a multichannel marketing strategy. A central hub of product data can be used to distribute information to sales channels such as e-commerce websites, print catalogues, marketplaces such as Amazon and Google Shopping, social media platforms like Instagram and electronic data feeds to trading partners. Moreover, the significant role that PIM plays is reducing the abandonment rate by giving better product information.

An owner's manual is an instructional book or booklet that is supplied with almost all technologically advanced consumer products such as vehicles, home appliances and computer peripherals. Information contained in the owner's manual typically includes:

Production Part Approval Process (PPAP) is used in the Aerospace or automotive supply chain for establishing confidence in suppliers and their production processes. Actual measurements are taken from the parts produced and are used to complete the various test sheets of PPAP.

"All customer engineering design record and specification requirements are properly understood by the supplier and that the process has the potential to produce product consistently meeting these requirements during an actual production run at the quoted production rate." Version 4, 1 March 2006

ETKA is the official electronic parts catalogue for Volkswagen Group motor vehicles. Launched in 1989, ETKA superseded the older parts books and microfilm-based catalogues. ETKA is an abbreviation from the German: Elektronischer Teilekatalog. It is produced for Volkswagen AG by the Munich-based specialist automotive industry information systems software publisher LexCom Informationssysteme GmbH. As of March 2023 the latest release of the ETKA software is ETKA 8.6. which includes workshop manual pages more photos and the ability to upload photos.

The NATO Codification System (NCS) is a Standardization Agreement approach to identify, classify, and number items of supply. This applies to repetitively used and stocked items. The System has been agreed upon by all signatories of the NATO and sponsored non-NATO nations for use in identifying equipment and supplies. The result is a unique identification and a data set that can be easily shared and understood by a wide range of users. The data set may be shared in the form of printed catalogs, online systems, electronic data exchange, etc. Users include logisticians and manufacturers.

Fuel-management systems are used to maintain, control and monitor fuel consumption and stock in any type of industry that uses transport, including rail, road, water and air, as a means of business. Fuel-management systems are designed to effectively measure and manage the use of fuel within the transportation and construction industries. They are typically used for fleets of vehicles, including railway vehicles and aircraft, as well as any vehicle that requires fuel to operate. They employ various methods and technologies to monitor and track fuel inventories, fuel purchases and fuel dispensed. This information can be then stored in computerized systems and reports generated with data to inform management practices. Online fuel management is provided through the use of web portals to provide detailed fueling data, usually vis a vis the back end of an automated fuel-management system. This enables consumption control, cost analysis and tax accounting for fuel purchases.

A specification often refers to a set of documented requirements to be satisfied by a material, design, product, or service. A specification is often a type of technical standard.

Functional safety is the part of the overall safety of a system or piece of equipment that depends on automatic protection operating correctly in response to its inputs or failure in a predictable manner (fail-safe). The automatic protection system should be designed to properly handle likely systematic errors, hardware failures and operational/environmental stress.

ISO 26262, titled "Road vehicles – Functional safety", is an international standard for functional safety of electrical and/or electronic systems that are installed in serial production road vehicles, defined by the International Organization for Standardization (ISO) in 2011, and revised in 2018.

Robustness validation is a skills strategy with which the Robustness of a product to the loading conditions of a real application is proven and targeted statements about risks and reliability can be made. This strategy is particularly for use in the automotive industry however could be applied to any industry where high levels of reliability are required