A screwdriver is a tool, manual or powered, used for driving screws. A typical simple screwdriver has a handle and a shaft, ending in a tip the user puts into the screw head before turning the handle. This form of the screwdriver has been replaced in many workplaces and homes with a more modern and versatile tool, a power drill, as they are quicker, easier, and can also drill holes. The shaft is usually made of tough steel to resist bending or twisting. The tip may be hardened to resist wear, treated with a dark tip coating for improved visual contrast between tip and screw—or ridged or treated for additional 'grip'. Handles are typically wood, metal, or plastic and usually hexagonal, square, or oval in cross-section to improve grip and prevent the tool from rolling when set down. Some manual screwdrivers have interchangeable tips that fit into a socket on the end of the shaft and are held in mechanically or magnetically. These often have a hollow handle that contains various types and sizes of tips, and a reversible ratchet action that allows multiple full turns without repositioning the tip or the user's hand.

A drill is a tool used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driverchuck. with hand-operated types dramatically decreasing in popularity and cordless battery-powered ones proliferating.

Taps and dies are tools used to create screw threads, which is called threading. Many are cutting tools; others are forming tools. A tap is used to cut or form the female portion of the mating pair. A die is used to cut or form the male portion of the mating pair. The process of cutting or forming threads using a tap is called tapping, whereas the process using a die is called threading.

Drills are cutting tools used to remove material to create holes, almost always of circular cross-section. Drills come in many sizes and shapes and can create different kinds of holes in many different materials. In order to create holes drill bits are usually attached to a drill, which powers them to cut through the workpiece, typically by rotation. The drill will grasp the upper end of a bit called the shank in the chuck.

Torx is a trademark for a type of screw drive characterized by a 6-point star-shaped pattern, developed in 1967 by Camcar Textron. A popular generic name for the drive is star, as in star screwdriver or star bits. The official generic name, standardized by the International Organization for Standardization as ISO 10664, is hexalobular internal. This is sometimes abbreviated in databases and catalogs as 6lobe. Torx Plus,Torx Paralobe and Torx ttap are improved head profiles.

A rivet is a permanent mechanical fastener. Before being installed, a rivet consists of a smooth cylindrical shaft with a head on one end. The end opposite to the head is called the tail. On installation, the rivet is placed in a punched or drilled hole, and the tail is upset, or bucked, so that it expands to about 1.5 times the original shaft diameter, holding the rivet in place. In other words, the pounding or pulling creates a new "head" on the tail end by smashing the "tail" material flatter, resulting in a rivet that is roughly a dumbbell shape. To distinguish between the two ends of the rivet, the original head is called the factory head and the deformed end is called the shop head or buck-tail.

A bolted joint is one of the most common elements in construction and machine design. It consist of a male threaded fastener that captures and joins other parts, secured with a matching female screw thread. There are two main types of bolted joint designs: tension joints and shear joints.

A self-tapping screw is a screw that can tap its own hole as it is driven into the material. More narrowly, self-tapping is used only to describe a specific type of thread-cutting screw intended to produce a thread in relatively soft material or sheet materials, excluding wood screws. Other specific types of self-tapping screw include self-drilling screws and thread rolling screws.

A screw thread, often shortened to thread, is a helical structure used to convert between rotational and linear movement or force. A screw thread is a ridge wrapped around a cylinder or cone in the form of a helix, with the former being called a straight thread and the latter called a tapered thread. A screw thread is the essential feature of the screw as a simple machine and also as a threaded fastener.

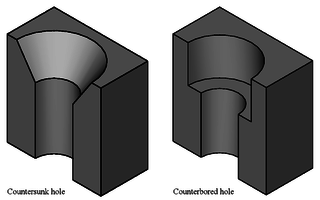

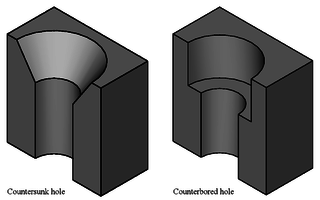

A countersink is a conical hole cut into a manufactured object, or the cutter used to cut such a hole. A common use is to allow the head of a countersunk bolt, screw or rivet, when placed in the hole, to sit flush with or below the surface of the surrounding material. A countersink may also be used to remove the burr left from a drilling or tapping operation thereby improving the finish of the product and removing any hazardous sharp edges.

A Robertson screw, also known as a square screw or Scrulox, is a type of screw with a square-shaped socket in the screw head and a corresponding square protrusion on the tool. Both the tool and socket have a slight taper. Originally designed to enable the screws to be made using cold forming of the heads, the taper has two other advantages which have helped popularize it: It makes inserting the tool easier, and helps keep the screw on the tool without the user having to hold it there. The Robertson screw is specified as ANSI Type III Square Center.

A screw is a mechanism that converts rotational motion to linear motion, and a torque to a linear force. It is one of the six classical simple machines. The most common form consists of a cylindrical shaft with helical grooves or ridges called threads around the outside. The screw passes through a hole in another object or medium, with threads on the inside of the hole that mesh with the screw's threads. When the shaft of the screw is rotated relative to the stationary threads, the screw moves along its axis relative to the medium surrounding it; for example rotating a wood screw forces it into wood. In screw mechanisms, either the screw shaft can rotate through a threaded hole in a stationary object, or a threaded collar such as a nut can rotate around a stationary screw shaft. Geometrically, a screw can be viewed as a narrow inclined plane wrapped around a cylinder.

A sex bolt is a type of mating fastener (nut) that has a barrel-shaped flange and protruding boss that is internally threaded. The bolts sits within the components being fastened, the flange provides the bearing surface. The sex bolt and accompanying machine screw sit flush on either side of the surfaces being fastened.

A threaded insert, also known as a threaded bushing, is a fastener element that is inserted into an object to add a threaded hole. They may be used to repair a stripped threaded hole, provide a durable threaded hole in a soft material, place a thread on a material too thin to accept it, mold or cast threads into a work piece thereby eliminating a machining operation, or simplify changeover from unified to metric threads or vice versa.

A pilot hole is a small hole drilled into a piece of construction material. Its purpose may be:

- to guide a larger drill to the appropriate location and ease the job of the larger drill

- allow for the insertion of another hole-making tool, such as a knockout punch, that will produce the final-sized hole, or

- locate, guide, and provide clearance for a self-threading screw in wood or plastic to prevent damaging the material or breaking the screw.

A screw and a bolt are similar types of fastener typically made of metal and characterized by a helical ridge, called a male thread. Screws and bolts are used to fasten materials by the engagement of the screw thread with a similar female thread in a matching part.

In manufacturing, threading is the process of creating a screw thread. More screw threads are produced each year than any other machine element. There are many methods of generating threads, including subtractive methods ; deformative or transformative methods ; additive methods ; or combinations thereof.

A screw extractor is a tool for removing broken or seized screws. There are two types: one has a spiral flute structure, commonly called an easy out after the trademarked name EZ-Out; the other has a straight flute structure. Screw extractors are intentionally made of hard, brittle steel, and, if too much torque is applied, can break off inside the screw that is being removed. Since the extractor is an extremely hard material, and a typical home shop drill bit will not be able to drill into it, a larger element of difficulty is added to the original screw extraction project. One way to avoid this added difficulty is to drill a hole completely through the screw. Thus, if the fastener breaks, a punch can be used to drive out the easy out from the screw, via the back, or end, of the fastener.

A bolt is a form of threaded fastener with an external male thread requiring a matching pre-formed female thread such as a nut. Bolts are very closely related to screws.