Related Research Articles

Metallurgy is a domain of materials science and engineering that studies the physical and chemical behavior of metallic elements, their inter-metallic compounds, and their mixtures, which are known as alloys. Metallurgy encompasses both the science and the technology of metals; that is, the way in which science is applied to the production of metals, and the engineering of metal components used in products for both consumers and manufacturers. Metallurgy is distinct from the craft of metalworking. Metalworking relies on metallurgy in a similar manner to how medicine relies on medical science for technical advancement. A specialist practitioner of metallurgy is known as a metallurgist.

Henry Louis Le Chatelier was a French chemist of the late 19th and early 20th centuries. He devised Le Chatelier's principle, used by chemists and chemical engineers to predict the effect a changing condition has on a system in chemical equilibrium.

Electropolishing, also known as electrochemical polishing, anodic polishing, or electrolytic polishing, is an electrochemical process that removes material from a metallic workpiece, reducing the surface roughness by levelling micro-peaks and valleys, improving the surface finish. Electropolishing is often compared to, but distinctly different from, electrochemical machining. It is used to polish, passivate, and deburr metal parts. It is often described as the reverse of electroplating. It may be used in lieu of abrasive fine polishing in microstructural preparation.

Copper extraction refers to the methods used to obtain copper from its ores. The conversion of copper ores consists of a series of physical, chemical and electrochemical processes. Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors.

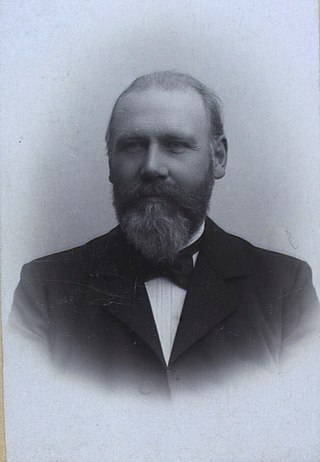

Henry Clifton Sorby was an English microscopist and geologist. His major contribution was the development of techniques for studying iron and steel with microscopes. This paved the way for the mass production of steel.

Hydrogen embrittlement (HE), also known as hydrogen-assisted cracking or hydrogen-induced cracking (HIC), is a reduction in the ductility of a metal due to absorbed hydrogen. Hydrogen atoms are small and can permeate solid metals. Once absorbed, hydrogen lowers the stress required for cracks in the metal to initiate and propagate, resulting in embrittlement. Hydrogen embrittlement occurs most notably in steels, as well as in iron, nickel, titanium, cobalt, and their alloys. Copper, aluminium, and stainless steels are less susceptible to hydrogen embrittlement.

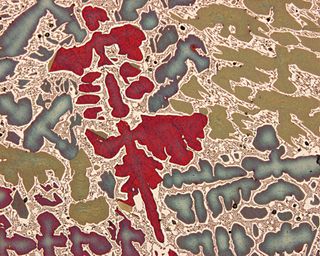

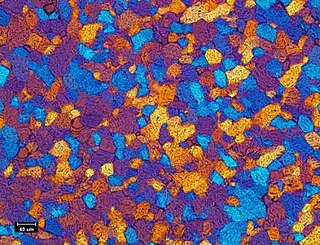

Metallography is the study of the physical structure and components of metals, by using microscopy.

Archaeometallurgy is the study of the past use and production of metals by humans. It is a sub-discipline of archaeology and archaeological science.

Ceramography is the art and science of preparation, examination and evaluation of ceramic microstructures. Ceramography can be thought of as the metallography of ceramics. The microstructure is the structure level of approximately 0.1 to 100 µm, between the minimum wavelength of visible light and the resolution limit of the naked eye. The microstructure includes most grains, secondary phases, grain boundaries, pores, micro-cracks and hardness microindentations. Most bulk mechanical, optical, thermal, electrical and magnetic properties are significantly affected by the microstructure. The fabrication method and process conditions are generally indicated by the microstructure. The root cause of many ceramic failures is evident in the microstructure. Ceramography is part of the broader field of materialography, which includes all the microscopic techniques of material analysis, such as metallography, petrography and plastography. Ceramography is usually reserved for high-performance ceramics for industrial applications, such as 85–99.9% alumina (Al2O3) in Fig. 1, zirconia (ZrO2), silicon carbide (SiC), silicon nitride (Si3N4), and ceramic-matrix composites. It is seldom used on whiteware ceramics such as sanitaryware, wall tiles and dishware.

Tanjore Ramachandra Anantharaman was one of India's pre-eminent metallurgists and materials scientists.

Holger F. Struer was a Danish chemist and founder of "H. Struers Chemiske Laboratorium" in 1875 at Skindergade 38, the centre of Copenhagen. Struers introduced in 1943 Micropol, a new principle for electrolytic polishing which made the preparation process within metallography more controlled in order to achieve better preparation results.

Acute beryllium poisoning is acute chemical pneumonitis resulting from the toxic effect of beryllium in its elemental form or in various chemical compounds, and is distinct from berylliosis. After occupational safety procedures were put into place following the realization that the metal caused berylliosis around 1950, acute beryllium poisoning became extremely rare.

Metallurgical failure analysis is the process to determine the mechanism that has caused a metal component to fail. It can identify the cause of failure, providing insight into the root cause and potential solutions to prevent similar failures in the future, as well as culpability, which is important in legal cases. Resolving the source of metallurgical failures can be of financial interest to companies. The annual cost of corrosion in the United States was estimated by NACE International in 2012 to be $450 billion a year, a 67% increase compared to estimates for 2001. These failures can be analyzed to determine their root cause, which if corrected, would save reduce the cost of failures to companies.

Floris Osmond was a French scientist and engineer. He is known as one of the originators of metallography. He named several phases that occur in iron and steel microstructures such as martensite, after A. Martens, and cementite. A list of publications was published shortly after his death.

Günter Petzow is a German materials scientist and former director at the Max Planck Institute for Metals Research.

Struers is a Danish engineering company, providing equipment for metallography preparation and inspection. Holger F. Struer a Danish chemist founded Struers in 1875 in Copenhagen. Struers introduced Micropol, a new process for electrolytic polishing.[1]

Theresa Mary Vandecar Brassard was an American metallographer.

Friedrich Emil Heyn was a German metallurgist who introduced the quantitative metallurgy and is considered a pioneer of metallography techniques including the intercept method where the number of grains cutting a known length of random line segment is used to characterize the fine grain structure of metal alloys.

Léon Alexandre Guillet was a French metallurgist who studied the properties of metal alloys and developed martensitic and austenitic stainless steels. He served as a professor of metallurgy at the École Centrale Paris where he was a director from 1923 and played a key role in putting materials research on a scientific footing.

S. Paramasivan was an Indian chemist who served at the Madras Museum and at the Archaeological Survey of India as an archaeological chemist and was a pioneer of electrolytic restoration of bronze artefacts and chemical conservation techniques. He studied ancient painting techniques, metallurgy, and investigated some applications of nuclear physics in archaeology.

References

- ↑ Jacquet, Pierre A. (1956). "Electrolytic and chemical polishing". Metallurgical Reviews. 1 (1): 157–238. doi:10.1179/mtlr.1956.1.1.157. ISSN 0076-6690.

- ↑ Jacquet, P. A. (1935). "Electrolytic Method for obtaining Bright Copper Surfaces". Nature. 135 (3426): 1076. doi: 10.1038/1351076c0 . ISSN 0028-0836.

- ↑ Jacquet, P.A. (1962). "Le polissage électrolytique daims les techniques. réalisations et perspectives". Revue de Métallurgie. 59 (12): 1055–1069. doi:10.1051/metal/196259121055. ISSN 0035-1563.

- ↑ Jacquet, P. A.; A. Van Effenterre (1957). "Méthode non destructive d'examens macro et micrographiques superficiels". Revue de Métallurgie. 54 (2): 107–125. doi:10.1051/metal/195754020107. S2CID 114572864.

- 1 2 Lacombe, P. (1968). "Pierre Jacquet (1906–1967)". Metallography. 1 (1): 1–3. doi:10.1016/0026-0800(68)90012-8.

- ↑ "2019 Jacquet-Lucas Award for Excellence in Metallography". Metallography, Microstructure, and Analysis. 9 (1): 97–98. 2020. doi:10.1007/s13632-020-00618-5. ISSN 2192-9262. S2CID 210953851.