A valve is a device or natural object that regulates, directs or controls the flow of a fluid by opening, closing, or partially obstructing various passageways. Valves are technically fittings, but are usually discussed as a separate category. In an open valve, fluid flows in a direction from higher pressure to lower pressure. The word is derived from the Latin valva, the moving part of a door, in turn from volvere, to turn, roll.

Laboratory glassware refers to a variety of equipment used in scientific work, and traditionally made of glass. Glass can be blown, bent, cut, molded, and formed into many sizes and shapes, and is therefore common in chemistry, biology, and analytical laboratories. Many laboratories have training programs to demonstrate how glassware is used and to alert first–time users to the safety hazards involved with using glassware.

A burette is a graduated glass tube with a tap at one end, for delivering known volumes of a liquid, especially in titrations. It is a long, graduated glass tube, with a stopcock at its lower end and a tapered capillary tube at the stopcock's outlet. The flow of liquid from the tube to the burette tip is controlled by the stopcock valve.

A check valve, non-return valve, reflux valve, retention valve, foot valve, or one-way valve is a valve that normally allows fluid to flow through it in only one direction.

A tap is a valve controlling the release of a fluid.

A gate valve, also known as a sluice valve, is a valve that opens by lifting a barrier (gate) out of the path of the fluid. Gate valves require very little space along the pipe axis and hardly restrict the flow of fluid when the gate is fully opened. The gate faces can be parallel but are most commonly wedge-shaped.

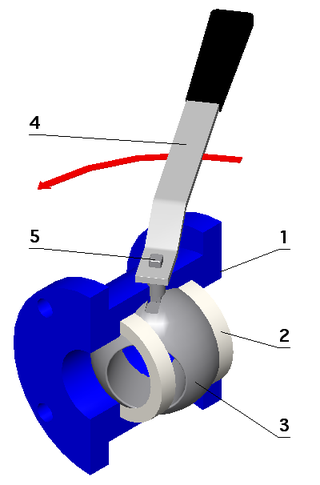

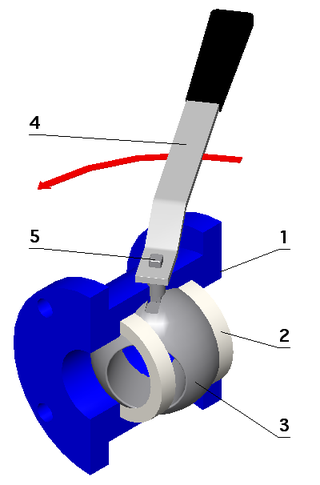

A ball valve is a flow control device which uses a hollow, perforated, and pivoting ball to control fluid flowing through it. It is open when the hole through the middle of the ball is in line with the flow inlet, and closed when it is pivoted 90 degrees by the valve handle, blocking the flow. The handle lies flat in alignment with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve's status. The shut position 1/4 turn could be in either clockwise or counter-clockwise direction.

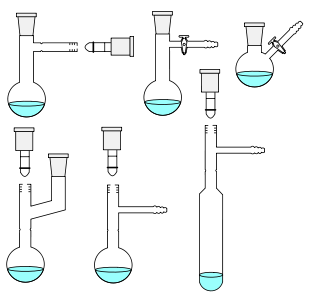

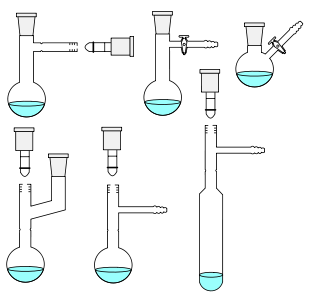

Laboratory flasks are vessels or containers that fall into the category of laboratory equipment known as glassware. In laboratory and other scientific settings, they are usually referred to simply as flasks. Flasks come in a number of shapes and a wide range of sizes, but a common distinguishing aspect in their shapes is a wider vessel "body" and one narrower tubular sections at the top called necks which have an opening at the top. Laboratory flask sizes are specified by the volume they can hold, typically in metric units such as milliliters or liters. Laboratory flasks have traditionally been made of glass, but can also be made of plastic.

A globe valve, different from ball valve, is a type of valve used for regulating flow in a pipeline, consisting of a movable plug or disc element and a stationary ring seat in a generally spherical body.

A hermetic seal is any type of sealing that makes a given object airtight. The term originally applied to airtight glass containers, but as technology advanced it applied to a larger category of materials, including rubber and plastics. Hermetic seals are essential to the correct and safe functionality of many electronic and healthcare products. Used technically, it is stated in conjunction with a specific test method and conditions of use. Colloquially, the exact requirements of such a seal varies with the application.

A needle valve is a type of valve with a small port and a threaded, needle-shaped plunger. It allows precise regulation of flow, although it is generally only capable of relatively low flow rates.

In internal combustion engines with carburetors, a choke valve or choke modifies the air pressure in the intake manifold, thereby altering the air–fuel ratio entering the engine. Choke valves are generally used in naturally aspirated engines to supply a richer fuel mixture when starting the engine. Most choke valves in engines are butterfly valves mounted upstream of the carburetor jet to produce a higher partial vacuum, which increases the fuel draw.

A stopcock is a form of valve used to control the flow of a liquid or gas. The term is not precise and is applied to many different types of valve. The only consistent attribute is that the valve is designed to completely stop the flow when closed fully.

Round-bottom flasks are types of flasks having spherical bottoms used as laboratory glassware, mostly for chemical or biochemical work. They are typically made of glass for chemical inertness; and in modern days, they are usually made of heat-resistant borosilicate glass. There is at least one tubular section known as the neck with an opening at the tip. Two- or three-necked flasks are common as well. Round bottom flasks come in many sizes, from 5 mL to 20 L, with the sizes usually inscribed on the glass. In pilot plants even larger flasks are encountered.

The Schlenk line is a commonly used chemistry apparatus developed by Wilhelm Schlenk. It consists of a dual manifold with several ports. One manifold is connected to a source of purified inert gas, while the other is connected to a vacuum pump. The inert-gas line is vented through an oil bubbler, while solvent vapors and gaseous reaction products are prevented from contaminating the vacuum pump by a liquid-nitrogen or dry-ice/acetone cold trap. Special stopcocks or Teflon taps allow vacuum or inert gas to be selected without the need for placing the sample on a separate line.

A Schlenk flask, or Schlenk tube, is a reaction vessel typically used in air-sensitive chemistry, invented by Wilhelm Schlenk. It has a side arm fitted with a PTFE or ground glass stopcock, which allows the vessel to be evacuated or filled with gases. These flasks are often connected to Schlenk lines, which allow both operations to be done easily.

Ground glass joints are used in laboratories to quickly and easily fit leak-tight apparatus together from interchangeable commonly available parts. For example, a round bottom flask, Liebig condenser, and oil bubbler with ground glass joints may be rapidly fitted together to reflux a reaction mixture. This is a large improvement compared with older methods of custom-made glassware, which was time-consuming and expensive, or the use of less chemical resistant and heat resistant corks or rubber bungs and glass tubes as joints, which took time to prepare as well.

Air-free techniques refer to a range of manipulations in the chemistry laboratory for the handling of compounds that are air-sensitive. These techniques prevent the compounds from reacting with components of air, usually water and oxygen; less commonly carbon dioxide and nitrogen. A common theme among these techniques is the use of a fine (100–10−3 Torr) or high (10−3–10−6 Torr) vacuum to remove air, and the use of an inert gas: preferably argon, but often nitrogen.

Cannula transfer or cannulation is a set of air-free techniques used with a Schlenk line, in transferring liquid or solution samples between reaction vessels via cannulae, avoiding atmospheric contamination. While the syringes are not the same as cannulae, the techniques remain relevant.