Labour economics, or labor economics, seeks to understand the functioning and dynamics of the markets for wage labour. Labour is a commodity that is supplied by labourers, usually in exchange for a wage paid by demanding firms. Because these labourers exist as parts of a social, institutional, or political system, labour economics must also account for social, cultural and political variables.

Accuracy and precision are two measures of observational error:

Cost accounting is defined by the Institute of Management Accountants as "a systematic set of procedures for recording and reporting measurements of the cost of manufacturing goods and performing services in the aggregate and in detail. It includes methods for recognizing, allocating, aggregating and reporting such costs and comparing them with standard costs". Often considered a subset of managerial accounting, its end goal is to advise the management on how to optimize business practices and processes based on cost efficiency and capability. Cost accounting provides the detailed cost information that management needs to control current operations and plan for the future.

A sweatshop or sweat factory is a crowded workplace with very poor or illegal working conditions, including little to no breaks, inadequate work space, insufficient lighting and ventilation, or uncomfortably or dangerously high or low temperatures. The work may be difficult, tiresome, dangerous, climatically challenging, or underpaid. Employees in sweatshops may work long hours with unfair wages, regardless of laws mandating overtime pay or a minimum wage; child labor laws may also be violated. Women make up 85 to 90% of sweatshop workers and may be forced by employers to take birth control and routine pregnancy tests to avoid supporting maternity leave or providing health benefits.

Baron Gaspard Clair François Marie Riche de Prony was a French mathematician and engineer, who worked on hydraulics. He was born at Chamelet, Beaujolais, France and died in Asnières-sur-Seine, France.

Activity-based costing (ABC) is a costing method that identifies activities in an organization and assigns the cost of each activity to all products and services according to the actual consumption by each. Therefore, this model assigns more indirect costs (overhead) into direct costs compared to conventional costing.

Repeatability or test–retest reliability is the closeness of the agreement between the results of successive measurements of the same measure, when carried out under the same conditions of measurement. In other words, the measurements are taken by a single person or instrument on the same item, under the same conditions, and in a short period of time. A less-than-perfect test–retest reliability causes test–retest variability. Such variability can be caused by, for example, intra-individual variability and inter-observer variability. A measurement may be said to be repeatable when this variation is smaller than a predetermined acceptance criterion.

A time and motion study is a business efficiency technique combining the Time Study work of Frederick Winslow Taylor with the Motion Study work of Frank and Lillian Gilbreth. It is a major part of scientific management (Taylorism). After its first introduction, time study developed in the direction of establishing standard times, while motion study evolved into a technique for improving work methods. The two techniques became integrated and refined into a widely accepted method applicable to the improvement and upgrading of work systems. This integrated approach to work system improvement is known as methods engineering and it is applied today to industrial as well as service organizations, including banks, schools and hospitals.

Maynard operation sequence technique (MOST) is a predetermined motion time system that is used primarily in industrial settings to set the standard time in which a worker should perform a task. To calculate this, a task is broken down into individual motion elements, and each is assigned a numerical time value in units known as time measurement units, or TMUs, where 100,000 TMUs is equivalent to one hour. All the motion element times are then added together and any allowances are added, and the result is the standard time. It is more common in Asia whereas the original and more sophisticated Methods Time Measurement technique, better known as MTM, is a global standard.

Operations management is concerned with designing and controlling the production of goods and services, ensuring that businesses are efficient in using resources to meet customer requirements.

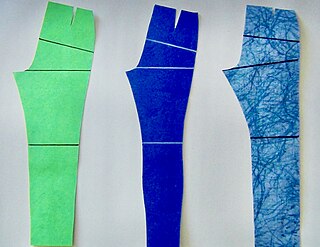

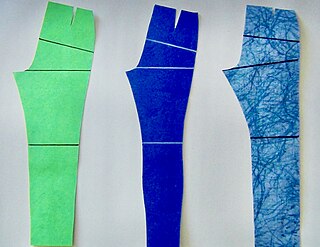

In sewing and fashion design, a pattern is the template from which the parts of a garment are traced onto woven or knitted fabrics before being cut out and assembled. Patterns are usually made of paper, and are sometimes made of sturdier materials like paperboard or cardboard if they need to be more robust to withstand repeated use. The process of making or cutting patterns is sometimes compounded to the one-word patternmaking, but it can also be written pattern making or pattern cutting.

In industrial engineering, the standard time is the time required by an average skilled operator, working at a normal pace, to perform a specified task using a prescribed method. It includes appropriate allowances to allow the person to recover from fatigue and, where necessary, an additional allowance to cover contingent elements which may occur but have not been observed.

Methods-Time Measurement (MTM) is a predetermined motion time system that is used primarily in industrial settings to analyze the methods used to perform any manual operation or task and, as a product of that analysis, to set the standard time in which a worker should complete that task.

Made-to-measure (MTM) typically refers to custom clothing that is cut and sewn using a standard-sized base pattern. Suits and sport coats are the most common garments made-to-measure. The fit of a made-to-measure garment is expected to be superior to that of a ready-to-wear garment because made-to-measure garments are constructed to fit each customer individually based on a few body measurements to customize the pre-existing pattern. Made-to-measure garments always involve some form of standardization in the pattern and manufacturing, whereas bespoke tailoring is entirely made from scratch based on a customer's specifications with far more attention to minute fit details and using multiple fittings during the construction process. All else being equal, a made-to-measure garment will be more expensive than a ready-to-wear garment but cheaper than a bespoke one. "Custom made" most often refers to MTM.

Work measurement is the application of techniques which is designed to establish the time for an average worker to carry out a specified manufacturing task at a defined level of performance. It is concerned with the duration of time it takes to complete a work task assigned to a specific job. It means the time taken to complete one unit of work or operation it also that the work should completely complete in a complete basis under certain circumstances which take into account of accountants time

Industrial engineering is an engineering profession that is concerned with the optimization of complex processes, systems, or organizations by developing, improving and implementing integrated systems of people, money, knowledge, information and equipment. Industrial engineering is central to manufacturing operations.

Work sampling is the statistical technique used for determining the proportion of time spent by workers in various defined categories of activity. It is as important as all other statistical techniques because it permits quick analysis, recognition, and enhancement of job responsibilities, tasks, performance competencies, and organizational work flows. Other names used for it are 'activity sampling', 'occurrence sampling', and 'ratio delay study'.

Performance rating is the step in the work measurement in which the analyst observes the worker's performance and records a value representing that performance relative to the analyst's concept of standard performance.

Clothing industry or garment industry summarizes the types of trade and industry along the production and value chain of clothing and garments, starting with the textile industry, embellishment using embroidery, via the fashion industry to apparel retailers up to trade with second-hand clothes and textile recycling. The producing sectors build upon a wealth of clothing technology some of which, like the loom, the cotton gin, and the sewing machine heralded industrialization not only of the previous textile manufacturing practices. Clothing industries are also known as allied industries, fashion industries, garment industries, or soft goods industries.