In telecommunications, RS-232 or Recommended Standard 232 is a standard originally introduced in 1960 for serial communication transmission of data. It formally defines signals connecting between a DTE such as a computer terminal, and a DCE, such as a modem. The standard defines the electrical characteristics and timing of signals, the meaning of signals, and the physical size and pinout of connectors. The current version of the standard is TIA-232-F Interface Between Data Terminal Equipment and Data Circuit-Terminating Equipment Employing Serial Binary Data Interchange, issued in 1997. The RS-232 standard had been commonly used in computer serial ports and is still widely used in industrial communication devices.

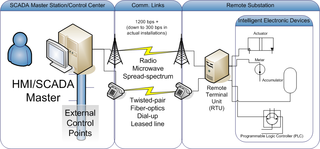

Supervisory control and data acquisition (SCADA) is a control system architecture comprising computers, networked data communications and graphical user interfaces for high-level supervision of machines and processes. It also covers sensors and other devices, such as programmable logic controllers, which interface with process plant or machinery.

Electronic test equipment is used to create signals and capture responses from electronic devices under test (DUTs). In this way, the proper operation of the DUT can be proven or faults in the device can be traced. Use of electronic test equipment is essential to any serious work on electronics systems.

DMX512 is a standard for digital communication networks that are commonly used to control lighting and effects. It was originally intended as a standardized method for controlling stage lighting dimmers, which, prior to DMX512, had employed various incompatible proprietary protocols. It quickly became the primary method for linking controllers to dimmers and special effects devices such as fog machines and intelligent lights.

A remote terminal unit (RTU) is a microprocessor-controlled electronic device that interfaces objects in the physical world to a distributed control system or SCADA system by transmitting telemetry data to a master system, and by using messages from the master supervisory system to control connected objects. Other terms that may be used for RTU are remote telemetry unit and remote telecontrol unit.

Modbus is a data communications protocol originally published by Modicon in 1979 for use with its programmable logic controllers (PLCs). Modbus has become a de facto standard communication protocol and is now a commonly available means of connecting industrial electronic devices.

RS-485, also known as TIA-485(-A) or EIA-485, is a standard, originally introduced in 1983, defining the electrical characteristics of drivers and receivers for use in serial communications systems. Electrical signaling is balanced, and multipoint systems are supported. The standard is jointly published by the Telecommunications Industry Association and Electronic Industries Alliance (TIA/EIA). Digital communications networks implementing the standard can be used effectively over long distances and in electrically noisy environments. Multiple receivers may be connected to such a network in a linear, multidrop bus. These characteristics make RS-485 useful in industrial control systems and similar applications.

An energy management system (EMS) is a system of computer-aided tools used by operators of electric utility grids to monitor, control, and optimize the performance of the generation or transmission system. Also, it can be used in small scale systems like microgrids. As electric vehicle (EV) charging becomes more popular smaller residential devices that manage when a EV can charge based on the total load vs total capacity of an electrical service are becoming popular.

A fieldbus is a member of a family of industrial digital communication networks used for real-time distributed control. Fieldbus profiles are standardized by the International Electrotechnical Commission (IEC) as IEC 61784/61158.

Industrial Ethernet (IE) is the use of Ethernet in an industrial environment with protocols that provide determinism and real-time control. Protocols for industrial Ethernet include EtherCAT, EtherNet/IP, PROFINET, POWERLINK, SERCOS III, CC-Link IE, and Modbus TCP. Many industrial Ethernet protocols use a modified Media Access Control (MAC) layer to provide low latency and determinism. Some microcontrollers such as Sitara provide industrial Ethernet support.

Power-system automation is the act of automatically controlling the power system via instrumentation and control devices. Substation automation refers to using data from Intelligent electronic devices (IED), control and automation capabilities within the substation, and control commands from remote users to control power-system devices.

Distributed Network Protocol 3 (DNP3) is a set of communications protocols used between components in process automation systems. Its main use is in utilities such as electric and water companies. Usage in other industries is not common. It was developed for communications between various types of data acquisition and control equipment. It plays a crucial role in SCADA systems, where it is used by SCADA Master Stations, Remote Terminal Units (RTUs), and Intelligent Electronic Devices (IEDs). It is primarily used for communications between a master station and RTUs or IEDs. ICCP, the Inter-Control Center Communications Protocol, is used for inter-master station communications. Competing standards include the older Modbus protocol and the newer IEC 61850 protocol.

A phasor measurement unit (PMU) is a device used to estimate the magnitude and phase angle of an electrical phasor quantity in the electricity grid using a common time source for synchronization. Time synchronization is usually provided by GPS or IEEE 1588 Precision Time Protocol, which allows synchronized real-time measurements of multiple remote points on the grid. PMUs are capable of capturing samples from a waveform in quick succession and reconstructing the phasor quantity, made up of an angle measurement and a magnitude measurement. The resulting measurement is known as a synchrophasor. These time synchronized measurements are important because if the grid’s supply and demand are not perfectly matched, frequency imbalances can cause stress on the grid, which is a potential cause for power outages.

An industrial control system (ICS) is an electronic control system and associated instrumentation used for industrial process control. Control systems can range in size from a few modular panel-mounted controllers to large interconnected and interactive distributed control systems (DCSs) with many thousands of field connections. Control systems receive data from remote sensors measuring process variables (PVs), compare the collected data with desired setpoints (SPs), and derive command functions that are used to control a process through the final control elements (FCEs), such as control valves.

Brake-by-wire technology in the automotive industry is the ability to control brakes through electronic means, without a mechanical connection that transfers force to the physical braking system from a driver input apparatus such as a pedal or lever.

IEC 60870 part 6 in electrical engineering and power system automation, is one of the IEC 60870 set of standards which define systems used for telecontrol in electrical engineering and power system automation applications. The IEC Technical Committee 57 have developed part 6 to provide a communication profile for sending basic telecontrol messages between two systems which is compatible with ISO standards and ITU-T recommendations.

IEC 60870 part 5 is one of the IEC 60870 set of standards which define systems used for telecontrol in electrical engineering and power system automation applications. Part 5 provides a communication profile for sending basic telecontrol messages between two systems, which uses permanent directly connected data circuits between the systems. The IEC Technical Committee 57 have developed a protocol standard for telecontrol, teleprotection, and associated telecommunications for electric power systems. The result of this work is IEC 60870-5. Five documents specify the base IEC 60870-5:

Operational technology (OT) is hardware and software that detects or causes a change, through the direct monitoring and/or control of industrial equipment, assets, processes and events. The term has become established to demonstrate the technological and functional differences between traditional information technology (IT) systems and industrial control systems environment, the so-called "IT in the non-carpeted areas".