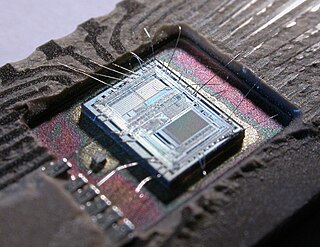

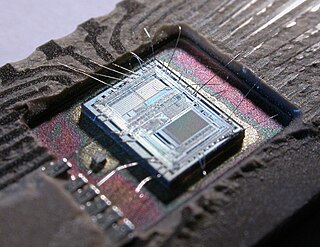

A field-programmable gate array (FPGA) is an integrated circuit designed to be configured by a customer or a designer after manufacturing – hence the term field-programmable. The FPGA configuration is generally specified using a hardware description language (HDL), similar to that used for an application-specific integrated circuit (ASIC). Circuit diagrams were previously used to specify the configuration, but this is increasingly rare due to the advent of electronic design automation tools.

A microcontroller is a small computer on a single VLSI integrated circuit (IC) chip. A microcontroller contains one or more CPUs along with memory and programmable input/output peripherals. Program memory in the form of ferroelectric RAM, NOR flash or OTP ROM is also often included on chip, as well as a small amount of RAM. Microcontrollers are designed for embedded applications, in contrast to the microprocessors used in personal computers or other general purpose applications consisting of various discrete chips.

An embedded system is a computer system—a combination of a computer processor, computer memory, and input/output peripheral devices—that has a dedicated function within a larger mechanical or electronic system. It is embedded as part of a complete device often including electrical or electronic hardware and mechanical parts. Because an embedded system typically controls physical operations of the machine that it is embedded within, it often has real-time computing constraints. Embedded systems control many devices in common use today. In 2009, it was estimated that ninety-eight percent of all microprocessors manufactured were used in embedded systems.

In computer engineering, a hardware description language (HDL) is a specialized computer language used to describe the structure and behavior of electronic circuits, and most commonly, digital logic circuits.

A system on a chip or system-on-chip is an integrated circuit that integrates most or all components of a computer or other electronic system. These components almost always include a central processing unit (CPU), memory interfaces, on-chip input/output devices, input/output interfaces, and secondary storage interfaces, often alongside other components such as radio modems and a graphics processing unit (GPU) – all on a single substrate or microchip. It may contain digital, analog, mixed-signal, and often radio frequency signal processing functions.

Reconfigurable computing is a computer architecture combining some of the flexibility of software with the high performance of hardware by processing with very flexible high speed computing fabrics like field-programmable gate arrays (FPGAs). The principal difference when compared to using ordinary microprocessors is the ability to make substantial changes to the datapath itself in addition to the control flow. On the other hand, the main difference from custom hardware, i.e. application-specific integrated circuits (ASICs) is the possibility to adapt the hardware during runtime by "loading" a new circuit on the reconfigurable fabric.

Rapid application development (RAD), also called rapid application building (RAB), is both a general term for adaptive software development approaches, and the name for James Martin's method of rapid development. In general, RAD approaches to software development put less emphasis on planning and more emphasis on an adaptive process. Prototypes are often used in addition to or sometimes even instead of design specifications.

Mechatronics, also called mechatronics engineering, is an interdisciplinary branch of engineering that focuses on the integration of mechanical, electrical and electronic engineering systems, and also includes a combination of robotics, electronics, computer science, telecommunications, systems, control, and product engineering.

Software prototyping is the activity of creating prototypes of software applications, i.e., incomplete versions of the software program being developed. It is an activity that can occur in software development and is comparable to prototyping as known from other fields, such as mechanical engineering or manufacturing.

Hardware acceleration is the use of computer hardware designed to perform specific functions more efficiently when compared to software running on a general-purpose central processing unit (CPU). Any transformation of data that can be calculated in software running on a generic CPU can also be calculated in custom-made hardware, or in some mix of both.

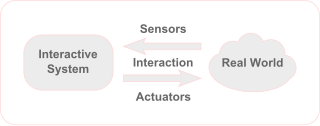

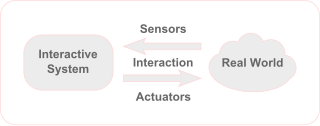

Physical computing involves interactive systems that can sense and respond to the world around them. While this definition is broad enough to encompass systems such as smart automotive traffic control systems or factory automation processes, it is not commonly used to describe them. In a broader sense, physical computing is a creative framework for understanding human beings' relationship to the digital world. In practical use, the term most often describes handmade art, design or DIY hobby projects that use sensors and microcontrollers to translate analog input to a software system, and/or control electro-mechanical devices such as motors, servos, lighting or other hardware.

In integrated circuit design, hardware emulation is the process of imitating the behavior of one or more pieces of hardware with another piece of hardware, typically a special purpose emulation system. The emulation model is usually based on a hardware description language source code, which is compiled into the format used by emulation system. The goal is normally debugging and functional verification of the system being designed. Often an emulator is fast enough to be plugged into a working target system in place of a yet-to-be-built chip, so the whole system can be debugged with live data. This is a specific case of in-circuit emulation.

Hardware-in-the-loop (HIL) simulation, HWIL, or HITL, is a technique that is used in the development and testing of complex real-time embedded systems. HIL simulation provides an effective testing platform by adding the complexity of the process-actuator system, known as a plant, to the test platform. The complexity of the plant under control is included in testing and development by adding a mathematical representation of all related dynamic systems. These mathematical representations are referred to as the "plant simulation". The embedded system to be tested interacts with this plant simulation.

Model-based design (MBD) is a mathematical and visual method of addressing problems associated with designing complex control, signal processing and communication systems. It is used in many motion control, industrial equipment, aerospace, and automotive applications. Model-based design is a methodology applied in designing embedded software.

EICASLAB is a software suite providing a laboratory for automatic control design and time-series forecasting developed as final output of the European ACODUASIS Project IPS-2001-42068 funded by the European Community within the Innovation Programme. The Project - during its lifetime - aimed at delivering in the robotic field the scientific breakthrough of a new methodology for the automatic control design.

In computing, an emulator is hardware or software that enables one computer system to behave like another computer system. An emulator typically enables the host system to run software or use peripheral devices designed for the guest system. Emulation refers to the ability of a computer program in an electronic device to emulate another program or device.

In computer engineering, computer architecture is a set of rules and methods that describe the functionality, organization, and implementation of computer systems. The architecture of a system refers to its structure in terms of separately specified components of that system and their interrelationships.

dSPACE GmbH, located in Paderborn, Germany, is one of the world's leading providers of tools for developing electronic control units.

Simcenter Amesim is a commercial simulation software for the modeling and analysis of multi-domain systems. It is part of systems engineering domain and falls into the mechatronic engineering field.

Predictive engineering analytics (PEA) is a development approach for the manufacturing industry that helps with the design of complex products. It concerns the introduction of new software tools, the integration between those, and a refinement of simulation and testing processes to improve collaboration between analysis teams that handle different applications. This is combined with intelligent reporting and data analytics. The objective is to let simulation drive the design, to predict product behavior rather than to react on issues which may arise, and to install a process that lets design continue after product delivery.