Concrete is a composite material composed of fine and coarse aggregate bonded together with a fluid cement that hardens (cures) over time. Concrete is the second-most-used substance in the world after water, and is the most widely used building material. Its usage worldwide, ton for ton, is twice that of steel, wood, plastics, and aluminum combined. Globally, the ready-mix concrete industry, the largest segment of the concrete market, is projected to exceed $600 billion in revenue by 2025. This widespread use results in a number of environmental impacts. Most notably, the production process for cement produces large volumes of greenhouse gas emissions, leading to net 8% of global emissions. Other environmental concerns include widespread illegal sand mining, impacts on the surrounding environment such as increased surface runoff or urban heat island effect, and potential public health implications from toxic ingredients. Significant research and development is being done to try to reduce the emissions or make concrete a source of carbon sequestration, and increase recycled and secondary raw materials content into the mix to achieve a circular economy. Concrete is expected to be a key material for structures resilient to climate disasters, as well as a solution to mitigate the pollution of other industries, capturing wastes such as coal fly ash or bauxite tailings and residue.

Thermal insulation is the reduction of heat transfer between objects in thermal contact or in range of radiative influence. Thermal insulation can be achieved with specially engineered methods or processes, as well as with suitable object shapes and materials.

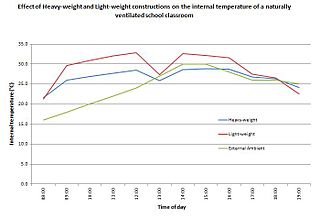

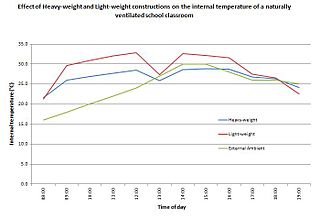

In building design, thermal mass is a property of the mass of a building which enables it to store heat, providing "inertia" against temperature fluctuations. It is sometimes known as the thermal flywheel effect. For example, when outside temperatures are fluctuating throughout the day, a large thermal mass within the insulated portion of a house can serve to "flatten out" the daily temperature fluctuations, since the thermal mass will absorb thermal energy when the surroundings are higher in temperature than the mass, and give thermal energy back when the surroundings are cooler, without reaching thermal equilibrium. This is distinct from a material's insulative value, which reduces a building's thermal conductivity, allowing it to be heated or cooled relatively separately from the outside, or even just retain the occupants' thermal energy longer.

An earth shelter, also called an earth house, earth bermed house, or underground house, is a structure with earth (soil) against the walls, on the roof, or that is entirely buried underground.

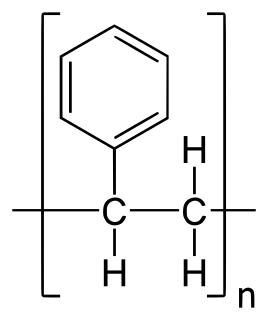

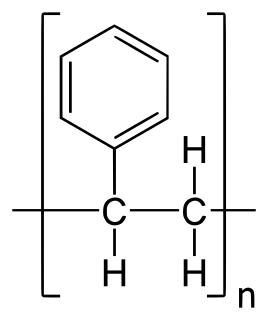

Polystyrene (PS) is a synthetic aromatic hydrocarbon polymer made from the monomer known as styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and brittle. It is an inexpensive resin per unit weight. It is a poor barrier to oxygen and water vapour and has a relatively low melting point. Polystyrene is one of the most widely used plastics, the scale of its production being several million tonnes per year. Polystyrene can be naturally transparent, but can be coloured with colourants. Uses include protective packaging, containers, lids, bottles, trays, tumblers, disposable cutlery, in the making of models, and as an alternative material for phonograph records.

In the context of construction, the R-value is a measure of how well a two-dimensional barrier, such as a layer of insulation, a window or a complete wall or ceiling, resists the conductive flow of heat. R-value is the temperature difference per unit of heat flux needed to sustain one unit of heat flux between the warmer surface and colder surface of a barrier under steady-state conditions.

Building material is material used for construction. Many naturally occurring substances, such as clay, rocks, sand, wood, and even twigs and leaves, have been used to construct buildings. Apart from naturally occurring materials, many man-made products are in use, some more and some less synthetic. The manufacturing of building materials is an established industry in many countries and the use of these materials is typically segmented into specific specialty trades, such as carpentry, insulation, plumbing, and roofing work. They provide the make-up of habitats and structures including homes.

A concrete masonry unit (CMU) is a standard-size rectangular block used in building construction. CMUs are some of the most versatile building products available because of the wide variety of appearances that can be achieved using them.

Insulating concrete form or insulated concrete form (ICF) is a system of formwork for reinforced concrete usually made with a rigid thermal insulation that stays in place as a permanent interior and exterior substrate for walls, floors, and roofs. The forms are interlocking modular units that are dry-stacked and filled with concrete. The units lock together somewhat like Lego bricks and create a form for the structural walls or floors of a building. ICF construction has become commonplace for both low rise commercial and high performance residential construction as more stringent energy efficiency and natural disaster resistant building codes are adopted.

A concrete slab is a common structural element of modern buildings, consisting of a flat, horizontal surface made of cast concrete. Steel-reinforced slabs, typically between 100 and 500 mm thick, are most often used to construct floors and ceilings, while thinner mud slabs may be used for exterior paving (see below).

Autoclaved aerated concrete (AAC) is a lightweight, precast, foam concrete building material suitable for producing concrete masonry unit like blocks. Composed of quartz sand, calcined gypsum, lime, cement, water and aluminum powder, AAC products are cured under heat and pressure in an autoclave. Invented in the mid-1920s, AAC simultaneously provides structure, insulation, and fire- and mold-resistance. Forms include blocks, wall panels, floor and roof panels, cladding (façade) panels and lintels.

Precast concrete is a construction product produced by casting concrete in a reusable mold or "form" which is then cured in a controlled environment, transported to the construction site and lifted into place. In contrast, cast-in-place concrete is poured into site-specific forms and cured on site. Precast stone is distinguished from precast concrete using a fine aggregate in the mixture, so the final product approaches the appearance of naturally occurring rock or stone. More recently expanded polystyrene is being used as the cores to precast wall panels. This is lightweight and has better thermal insulation.

Building insulation is any object in a building used as insulation for thermal management. While the majority of insulation in buildings is for thermal purposes, the term also applies to acoustic insulation, fire insulation, and impact insulation. Often an insulation material will be chosen for its ability to perform several of these functions at once.

Building insulation materials are the building materials which form the thermal envelope of a building or otherwise reduce heat transfer.

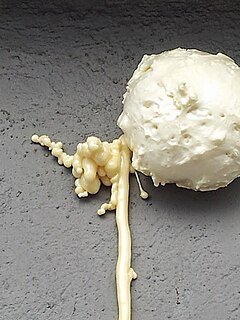

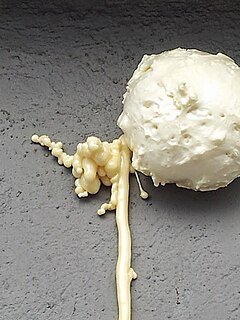

Spray foam is a chemical product created by two materials, isocyanate and polyol resin, which react when mixed with each other and expand up to 30-60 times its liquid volume after it is sprayed in place. This expansion makes it useful as a specialty packing material which forms to the shape of the product being packaged and produces a high thermal insulating value with virtually no air infiltration.

Rigid panel insulation, also referred to as continuous insulation, can be made from foam plastics such as polyurethane (PUR), polyisocyanurate (PIR), and polystyrene, or from fibrous materials such as fiberglass, rock and slag wool. Rigid panel continuous insulation is often used to provide a thermal break in the building envelope, thus reducing thermal bridging.

Hempcrete or hemplime is biocomposite material, a mixture of hemp hurds (shives) and lime, sand, or pozzolans, which is used as a material for construction and insulation. It is marketed under names like Hempcrete, Canobiote, Canosmose, Isochanvre and IsoHemp. Hempcrete is easier to work with than traditional lime mixes and acts as an insulator and moisture regulator. It lacks the brittleness of concrete and consequently does not need expansion joints. The result is a lightweight insulating material ideal for most climates as it combines insulation and thermal mass.

Wonderbag is a stand-alone, non-electric insulated bag designed to reduce the amount of fuel required in the cooking of food in developing countries. Instead of being placed on a stove for the duration of the cooking period, food is instead heated to a hot enough temperature then transferred to the Wonderbag, which uses the principle of thermal insulation to continue cooking, and keeps food warm without needing additional fire or heat. Working on the principle of thermal cooking, the Wonderbag is estimated to save up to 30% of the total fuel costs associated with cooking with Kerosene ("paraffin") alone. In developing countries there are numerous advantages for the product, as it immediately helps ease deforestation of natural reserves, and it frees up those who would spend their time gathering the extra wood for fire fuel.

Foam concrete, also known as Lightweight Cellular Concrete (LCC), Low Density Cellular Concrete (LDCC), and other terms is defined as a cement-based slurry, with a minimum of 20% foam entrained into the plastic mortar. As mostly no coarse aggregate is used for production of foam concrete the correct term would be called mortar instead of concrete; it may be called "foamed cement" as well. The density of foam concrete usually varies from 400 kg/m3 to 1600 kg/m3. The density is normally controlled by substituting fully or part of the fine aggregate with foam.

Waste light concrete (WLC) is a type of light weight concrete where the traditional construction aggregates are replaced by a mix of shredded waste materials and a special group of additives. Used in infrastructure and building construction.