In physics, cryogenics is the production and behaviour of materials at very low temperatures.

Refrigeration is any of various types of cooling of a space, substance, or system to lower and/or maintain its temperature below the ambient one. Refrigeration is an artificial, or human-made, cooling method.

The following is a timeline of low-temperature technology and cryogenic technology. It also lists important milestones in thermometry, thermodynamics, statistical physics and calorimetry, that were crucial in development of low temperature systems.

Freezing food preserves it from the time it is prepared to the time it is eaten. Since early times, farmers, fishermen, and trappers have preserved grains and produce in unheated buildings during the winter season. Freezing food slows decomposition by turning residual moisture into ice, inhibiting the growth of most bacterial species. In the food commodity industry, there are two processes: mechanical and cryogenic. The freezing kinetics is important to preserve the food quality and texture. Quicker freezing generates smaller ice crystals and maintains cellular structure. Cryogenic freezing is the quickest freezing technology available due to the ultra low liquid nitrogen temperature −196 °C (−320 °F).

A reefer ship is a refrigerated cargo ship typically used to transport perishable cargo, which require temperature-controlled handling, such as fruits, meat, vegetables, dairy products, and similar items.

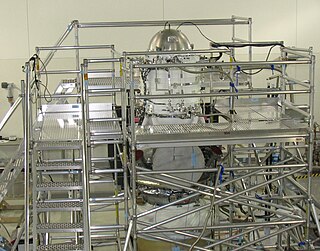

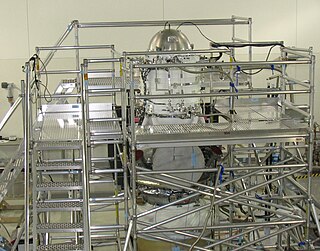

A cryostat is a device used to maintain low cryogenic temperatures of samples or devices mounted within the cryostat. Low temperatures may be maintained within a cryostat by using various refrigeration methods, most commonly using cryogenic fluid bath such as liquid helium. Hence it is usually assembled into a vessel, similar in construction to a vacuum flask or Dewar. Cryostats have numerous applications within science, engineering, and medicine.

A refrigerator, commonly fridge, is a commercial and home appliance consisting of a thermally insulated compartment and a heat pump that transfers heat from its inside to its external environment so that its inside is cooled to a temperature below the room temperature. Refrigeration is an essential food storage technique around the world. The low temperature reduces the reproduction rate of bacteria, so the refrigerator lowers the rate of spoilage. A refrigerator maintains a temperature a few degrees above the freezing point of water. The optimal temperature range for perishable food storage is 3 to 5 °C. A freezer is a specialized refrigerator, or portion of a refrigerator, that maintains its contents’ temperature below the freezing point of water. The refrigerator replaced the icebox, which had been a common household appliance for almost a century and a half. The United States Food and Drug Administration recommends that the refrigerator be kept at or below 4 °C (40 °F) and that the freezer be regulated at −18 °C (0 °F).

A refrigerator car is a refrigerated boxcar (U.S.), a piece of railroad rolling stock designed to carry perishable freight at specific temperatures. Refrigerator cars differ from simple insulated boxcars and ventilated boxcars, neither of which are fitted with cooling apparatus. Reefers can be ice-cooled, come equipped with any one of a variety of mechanical refrigeration systems, or use carbon dioxide or liquid nitrogen as a cooling agent. Milk cars may or may not include a cooling system, but are equipped with high-speed trucks and other modifications that allow them to travel with passenger trains.

A cold chain is a supply chain that uses refrigeration to maintain perishable goods, such as pharmaceuticals, produce or other goods that are temperature-sensitive. Common goods, sometimes called cool cargo, distributed in cold chains include fresh agricultural produce, seafood, frozen food, photographic film, chemicals, and pharmaceutical products. The objective of a cold chain is to preserve the integrity and quality of goods such as pharmaceutical products or perishable good from production to consumption.

An icemaker, ice generator, or ice machine may refer to either a consumer device for making ice, found inside a home freezer; a stand-alone appliance for making ice, or an industrial machine for making ice on a large scale. The term "ice machine" usually refers to the stand-alone appliance.

An absorption refrigerator is a refrigerator that uses a heat source to provide the energy needed to drive the cooling process. Solar energy, burning a fossil fuel, waste heat from factories, and district heating systems are examples of heat sources that can be used. An absorption refrigerator uses two coolants: the first coolant performs evaporative cooling and then is absorbed into the second coolant; heat is needed to reset the two coolants to their initial states. Absorption refrigerators are commonly used in recreational vehicles (RVs), campers, and caravans because the heat required to power them can be provided by a propane fuel burner, by a low-voltage DC electric heater or by a mains-powered electric heater. Absorption refrigerators can also be used to air-condition buildings using the waste heat from a gas turbine or water heater in the building. Using waste heat from a gas turbine makes the turbine very efficient because it first produces electricity, then hot water, and finally, air-conditioning—trigeneration.

Vapour-compression refrigeration or vapor-compression refrigeration system (VCRS), in which the refrigerant undergoes phase changes, is one of the many refrigeration cycles and is the most widely used method for air conditioning of buildings and automobiles. It is also used in domestic and commercial refrigerators, large-scale warehouses for chilled or frozen storage of foods and meats, refrigerated trucks and railroad cars, and a host of other commercial and industrial services. Oil refineries, petrochemical and chemical processing plants, and natural gas processing plants are among the many types of industrial plants that often utilize large vapor-compression refrigeration systems. Cascade refrigeration systems may also be implemented using two compressors.

A semi-trailer is a trailer without a front axle. The combination of a semi-trailer and a tractor truck is called a semi-trailer truck.

A refrigerator truck or chiller lorry, is a van or truck designed to carry perishable freight at low temperatures. Most long-distance refrigerated transport by truck is done in articulated trucks pulling refrigerated hardside (box) semi-trailers, although insulated curtainsiders are common in some countries. Occasionally, refrigerated trailers have been used as temporary morgues, and second-hand refrigerated trailers are frequently sold for use in tiny home conversions due to their insulation and existing status as a vehicle.

Thermo King is an American manufacturer of transport temperature control systems for refrigerator trucks and trailers, refrigerated containers and refrigerated railway cars along with heating, ventilation and air conditioning systems for bus and passenger rail applications. Headquartered in the Minneapolis suburb of Bloomington, Minnesota. Thermo King is a subsidiary of Trane Technologies.

A containerized housing unit, usually abbreviated as CHU is an ISO shipping container pre-fabricated into a living quarters. Such containers can be transported by container ships, railroad cars, planes, and trucks that are capable of transporting intermodal freight transport cargo.

A refrigerated van is a railway goods wagon with cooling equipment. Today they are designated by the International Union of Railways (UIC) as Class I.

A shipping container is a container with strength suitable to withstand shipment, storage, and handling. Shipping containers range from large reusable steel boxes used for intermodal shipments to the ubiquitous corrugated boxes. In the context of international shipping trade, "container" or "shipping container" is virtually synonymous with "intermodal freight container", a container designed to be moved from one mode of transport to another without unloading and reloading.

The International Institute of Refrigeration (IIR), is an independent intergovernmental science and technology-based organization which promotes knowledge of refrigeration and associated technologies and applications on a global scale that improve quality of life in a cost-effective and environmentally sustainable manner, including:

Urban freight distribution is the system and process by which goods are collected, transported, and distributed within urban environments. The urban freight system can include seaports, airports, manufacturing facilities, and warehouse/distribution centers that are connected by a network of railroads, rail yards, pipelines, highways, and roadways that enable goods to get to their destinations.