A carbon sink is any reservoir, natural or otherwise, that accumulates and stores some carbon-containing chemical compound for an indefinite period and thereby lowers the concentration of carbon dioxide (CO2) from the atmosphere.

Natural gas is a naturally occurring hydrocarbon gas mixture consisting of methane and commonly including varying amounts of other higher alkanes, and sometimes a small percentage of carbon dioxide, nitrogen, hydrogen sulfide, or helium. Natural gas is colorless and odorless, and explosive, so a sulfur-smell is usually added for early detection of leaks. Natural gas is formed when layers of decomposing plant and animal matter are exposed to intense heat and pressure under the surface of the Earth over millions of years. The energy that the plants originally obtained from the sun is stored in the form of chemical bonds in the gas. Natural gas is a fossil fuel.

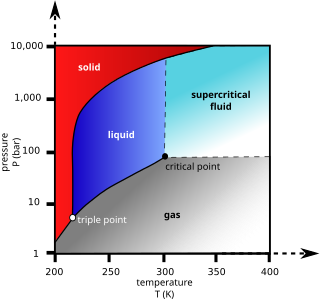

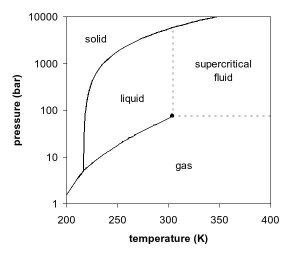

A supercritical fluid (SCF) is any substance at a temperature and pressure above its critical point, where distinct liquid and gas phases do not exist, but below the pressure required to compress it into a solid. It can effuse through porous solids like a gas, overcoming the mass transfer limitations that slow liquid transport through such materials. SCF are much superior to gases in their ability to dissolve materials like liquids or solids. In addition, close to the critical point, small changes in pressure or temperature result in large changes in density, allowing many properties of a supercritical fluid to be "fine-tuned".

Gas reinjection is the reinjection of natural gas into an underground reservoir, typically one already containing both natural gas and crude oil, in order to increase the pressure within the reservoir and thus induce the flow of crude oil or else sequester gas that cannot be exported. This is not to be confused with gas lift, where gas is injected into the annulus of the well rather than the reservoir. After the crude has been pumped out, the natural gas is once again recovered. Since many of the wells found around the world contain heavy crude, this process increases their production. The basic difference between light crude and heavy crude is its viscosity and pumpability—the lighter the crude the easier it is to pump. Recovery of hydrocarbons in a well is generally limited to 50% and 75–80%. Recycling of natural gas or other inert gases causes the pressure to rise in the well, thus causing more gas molecules to dissolve in the oil lowering its viscosity and thereby increasing the well's output. Air is not suitable for repressuring wells because it tends to cause deterioration of the oil, thus carbon dioxide or natural gas is used to repressure the well. The term 'gas-reinjection' is also sometimes referred to as repressuring—the term being used only to imply that the pressure inside the well is being increased to aid recovery.

Unconventional oil is petroleum produced or extracted using techniques other than the conventional method. Industry and governments across the globe are investing in unconventional oil sources due to the increasing scarcity of conventional oil reserves. Unconventional oil and gas have already made a dent in international energy linkages by reducing US energy import dependency.

Total organic carbon (TOC) is the amount of carbon found in an organic compound and is often used as a non-specific indicator of water quality or cleanliness of pharmaceutical manufacturing equipment. TOC may also refer to the amount of organic carbon in soil, or in a geological formation, particularly the source rock for a petroleum play; 2% is a rough minimum. For marine surface sediments average TOC content is 0.5% in the deep ocean, and 2% along the eastern margins.

Petroleum coke, abbreviated coke or petcoke, is a final carbon-rich solid material that derives from oil refining, and is one type of the group of fuels referred to as cokes. Petcoke is the coke that, in particular, derives from a final cracking process—a thermo-based chemical engineering process that splits long chain hydrocarbons of petroleum into shorter chains—that takes place in units termed coker units. Stated succinctly, coke is the "carbonization product of high-boiling hydrocarbon fractions obtained in petroleum processing ". Petcoke is also produced in the production of synthetic crude oil (syncrude) from bitumen extracted from Canada’s oil sands and from Venezuela's Orinoco oil sands.

Supercritical carbon dioxide is a fluid state of carbon dioxide where it is held at or above its critical temperature and critical pressure.

Carbon capture and storage (CCS) or carbon capture and sequestration is the process of capturing carbon dioxide before it enters the atmosphere, transporting it, and storing it for centuries or millennia. Usually the CO2 is captured from large point sources, such as a chemical plant or biomass power plant, and then stored in an underground geological formation. The aim is to prevent the release of CO2 from heavy industry with the intent of mitigating the effects of climate change. Although CO2 has been injected into geological formations for several decades for various purposes, including enhanced oil recovery, the long-term storage of CO2 is a relatively new concept. Carbon capture and utilization (CCU) and CCS are sometimes discussed collectively as carbon capture, utilization, and sequestration (CCUS). This is because CCS is a relatively expensive process yielding a product with an intrinsic low value. Hence, carbon capture makes economically more sense when being combined with a utilization process where the cheap CO2 can be used to produce high-value chemicals to offset the high costs of capture operations.

Enhanced oil recovery, also called tertiary recovery, is the extraction of crude oil from an oil field that cannot be extracted otherwise. EOR can extract 30% to 60% or more of a reservoir's oil, compared to 20% to 40% using primary and secondary recovery. According to the US Department of Energy, carbon dioxide and water are injected along with one of three EOR techniques: thermal injection, gas injection, and chemical injection. More advanced, speculative EOR techniques are sometimes called quaternary recovery.

Carbon sequestration is the process of storing carbon in a carbon pool. Carbon dioxide is naturally captured from the atmosphere through biological, chemical, and physical processes. These changes can be accelerated through changes in land use and agricultural practices, such as converting crop and livestock grazing land into land for non-crop fast growing plants. Artificial processes have been devised to produce similar effects, including large-scale, artificial capture and sequestration of industrially produced CO

2 using subsurface saline aquifers, reservoirs, ocean water, aging oil fields, or other carbon sinks, bio-energy with carbon capture and storage, biochar, ocean fertilization, enhanced weathering, and direct air capture when combined with storage.

Steam-assisted gravity drainage is an enhanced oil recovery technology for producing heavy crude oil and bitumen. It is an advanced form of steam stimulation in which a pair of horizontal wells is drilled into the oil reservoir, one a few metres above the other. High pressure steam is continuously injected into the upper wellbore to heat the oil and reduce its viscosity, causing the heated oil to drain into the lower wellbore, where it is pumped out. Dr. Roger Butler, engineer at Imperial Oil from 1955 to 1982, invented the steam assisted gravity drainage (SAGD) process in the 1970s. Butler "developed the concept of using horizontal pairs of wells and injected steam to develop certain deposits of bitumen considered too deep for mining". In 1983 Butler became director of technical programs for the Alberta Oil Sands Technology and Research Authority (AOSTRA), a crown corporation created by Alberta Premier Lougheed to promote new technologies for oil sands and heavy crude oil production. AOSTRA quickly supported SAGD as a promising innovation in oil sands extraction technology.

Carbon dioxide (CO2) flooding is a process whereby carbon dioxide is injected into oil reservoirs in order to increase output when extracting oil, especially in reservoirs where production rates have declined over time. The process was first attempted in 1977 in Scurrey County, Texas. Since then, the process has become extensively used in the Permian basin region of the US and is now more recently begun to be pursued in many different states, but still remains fairly uncommon outside of the United States.

Dissolved gas analysis (DGA) is an examination of electrical transformer oil contaminants. Insulating materials within electrical equipment liberate gases as they slowly break down over time. The composition and distribution of these dissolved gases are indicators of the effects of deterioration, such as pyrolysis or partial discharge, and the rate of gas generation indicates the severity. DGA is beneficial to a preventive maintenance program.

The extraction of petroleum is the process by which usable petroleum is drawn out from beneath the earth's surface location.

Enhanced coal bed methane recovery is a method of producing additional coalbed methane from a source rock, similar to enhanced oil recovery applied to oil fields. Carbon dioxide (CO2) injected into a bituminous coal bed would occupy pore space and also adsorb onto the carbon in the coal at approximately twice the rate of methane (CH4), allowing for potential enhanced gas recovery. This technique may be used in conjunction with carbon capture and storage in mitigation of global warming where the carbon dioxide that is sequestered is captured from the output of fossil fuel power plants.

A biogas upgrader is a facility that is used to concentrate the methane in biogas to natural gas standards. The system removes carbon dioxide, hydrogen sulphide, water and contaminants from the biogas. One technique for doing this uses amine gas treating. This purified biogas is also called biomethane. It can be used interchangeably with natural gas.

Heavy oil production is a developing technology for extracting heavy oil in industrial quantities. Estimated reserves of heavy oil are over 6 trillion barrels, three times that of conventional oil and gas.

The Weyburn-Midale Carbon Dioxide Project is, as of 2008, the world's largest carbon capture and storage project. It is located in Midale, Saskatchewan, Canada.

Navitas Land and Mineral Corporation is an oil and gas exploration, development and production firm headquartered in Madisonville, Kentucky. Founded in 2009, the company’s oil and gas recovery efforts are focused on the Illinois Basin, an area that encompasses Western Kentucky, Southern Illinois, and Southwestern Indiana.