In firearms terminology, an action is the functional mechanism of a breech-loading firearm that handles the ammunition cartridges, or the method by which that mechanism works. Actions are technically not present on muzzleloaders, as all those are single-shot firearms with a closed off breech with the powder and projectile manually loaded from the muzzle. Instead, the muzzleloader ignition mechanism is referred to as the lock.

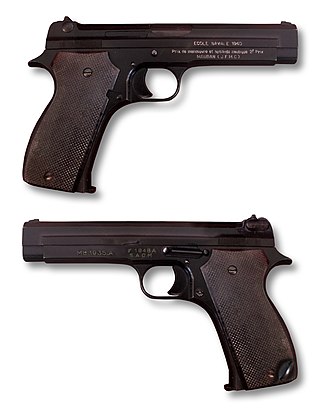

The Browning Hi-Power is a single-action, semi-automatic pistol available in the 9×19mm Parabellum and .40 S&W calibers. It was based on a design by American firearms inventor John Browning, and completed by Dieudonné Saive at FN Herstal. Browning died in 1926, several years before the design was finalized. FN Herstal named it the "High Power" in allusion to the 13-round magazine capacity, almost twice that of other designs at the time, such as the Walther P38 or Colt M1911.

A semi-automatic pistol is a handgun that automatically ejects and loads cartridges in its chamber after every shot fired. Only one round of ammunition is fired each time the trigger is pulled, as the pistol's fire control group disconnects the trigger mechanism from the firing pin/striker until the trigger has been released and reset.

The Beretta 92G-SD and 96G-SD Special Duty handguns are semi-automatic, locked-breech delayed recoil-operated, double/single-action pistols, fitted with the heavy, wide Brigadier slide, chambered for the 9×19mm Parabellum cartridge (92G-SD) and the .40 S&W cartridge (96G-SD), framed with the addition of the tactical equipment rail, designed and manufactured by Beretta.

The .357 SIG is a bottlenecked rimless centrefire handgun cartridge developed by the Swiss-German firearms manufacturer SIG Sauer, in cooperation with ammunition manufacturer Federal Premium. The cartridge is used by a number of law enforcement agencies.

The SIG Sauer P220 is a semi-automatic pistol designed in 1975 by the SIG Arms AG division of Schweizerische Industrie Gesellschaft, and produced by J. P. Sauer & Sohn, in Eckernförde. It is currently manufactured by both SIG Sauer companies: SIG Sauer GMBH, of Eckernförde, Germany; and SIG Sauer, Inc., of New Hampshire, United States.

Blowback is a system of operation for self-loading firearms that obtains energy from the motion of the cartridge case as it is pushed to the rear by expanding gas created by the ignition of the propellant charge.

A breechblock is the part of the firearm action that closes the breech of a breech loading weapon before or at the moment of firing. It seals the breech and contains the pressure generated by the ignited propellant. Retracting the breechblock allows the chamber to be loaded with a cartridge.

The USP is a semi-automatic pistol developed in Germany by Heckler & Koch GmbH (H&K) as a replacement for the P7 series of handguns.

Rotating bolt is a method of locking the breech of a firearm closed for firing. Johann Nicolaus von Dreyse developed the first rotating bolt firearm, the "Dreyse needle gun", in 1836. The Dreyse locked using the bolt handle rather than lugs on the bolt head like the Mauser M 98 or M16. The first rotating bolt rifle with two lugs on the bolt head was the Lebel Model 1886 rifle. The concept has been implemented on most firearms chambered for high-powered cartridges since the 20th century.

Locked breech is the design of a breech-reloading firearm's action. This is important in understanding how a self-reloading firearm works. In the simplest terms, the locked breech is one way to slow down the opening of the breech of a self-reloading firearm when fired. The source of power for the movement is recoil.

The Colt Model 1900 is a short-recoil operated "self-loading", or semi-automatic .38 caliber handgun introduced by Colt's Manufacturing Company at the turn of the 20th century. The M1900 was the first firearm to be chambered in .38 ACP and was the first handgun to utilize short-recoil operation.

Limp wristing is a phenomenon commonly encountered by semi-automatic pistol shooters, where the shooter's grip is not firm enough and the wrist is not held firm/straight enough to keep the frame of the firearm from traveling rearward while the bolt or slide of the firearm cycles. This condition often results in a failure to complete the operating cycle, properly termed a malfunction, but commonly termed a "jam". This phenomenon can affect metal or poly framed firearms equally. Both semi-automatic rifles and semi-automatic shotguns, if fired without the stock held against the shoulder correctly, may also be prone to limp wristing. Of the important variables involved in this type of malfunction, bullet and gas momentum, slide and barrel mass, recoil spring pre-load and spring rate, and shooting hand and arm mass are much more important than the compliance (limpness) of the wrist.

The following are terms related to firearms and ammunition topics.

FN HP-DA is a 9mm semi-automatic pistol developed by Belgian Fabrique Nationale arms factory in Herstal. In North American markets, it was marketed as the Browning BDA and is also referred to as Browning DA and Browning Hi-Power BDA.

Recoil operation is an operating mechanism used to implement locked-breech autoloading firearms. Recoil operated firearms use the energy of recoil to cycle the action, as opposed to gas operation or blowback operation using the pressure of the propellant gas.

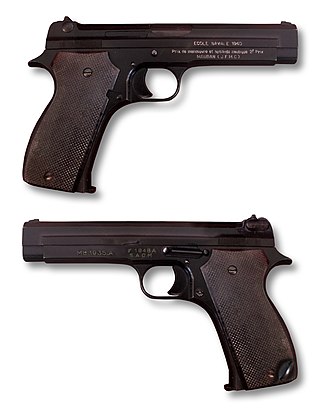

Charles Gabriel Petter was a Swiss firearms designer. He is best known as the designer of the Pistolet automatique modèle 1935A. He also designed a submachine gun that was patented and formally adopted into French service in 1939, but never produced.

The Remington R51 is a semi-automatic pistol announced in late 2013 by Remington Arms and was available to the market in January 2014. The R51 is a modernized version of the John Pedersen-designed Remington Model 51 pistol now chambered in 9×19mm +P caliber. Remington announced plans to offer the pistol in .40 S&W and other calibers. However, no other chamberings were offered by the time of Remington's bankruptcy in 2018.

The SIG Sauer P365 is a striker-fired subcompact semi-automatic pistol manufactured by SIG Sauer, intended for everyday carry. It is offered with Tritium XRAY3 Day/Night Sights and two 10-round magazines; one flush fit and the other with an extended finger tab, and a stainless steel frame with polymer grip module. It is primarily chambered in 9×19mm Parabellum and is rated for +P ammunition while utilizing offset double-stack magazines. A variant chambered in .380 ACP was introduced in February 2022. The P365, which replaced the P290RS, is produced in Newington, New Hampshire. In both 2018 and 2019, it was the best selling handgun in the United States.

The Pistolet automatique modèle 1935A commonly known by the abbreviation the SACM pistol, is a semi-automatic pistol designed by Charles Petter, chambered for the 7.65mm Longue cartridge. It was developed to compete in the 1935–1937 French military trials conducted by the Commission d’Experiences Techniques de Versailles to select a new sidearm.