Concrete is a composite material composed of aggregate bonded together with a fluid cement that cures to a solid over time. Concrete is the second-most-used substance in the world after water, and is the most widely used building material. Its usage worldwide, ton for ton, is twice that of steel, wood, plastics, and aluminium combined.

Masonry is the craft of building a structure with brick, stone, or similar material, including mortar plastering which are often laid in, bound, and pasted together by mortar. The term masonry can also refer to the building units themselves.

A road is a thoroughfare for the conveyance of traffic that mostly has an improved surface for use by vehicles and pedestrians. Unlike streets, whose primary function is to serve as public spaces, the main function of roads is transportation.

Water content or moisture content is the quantity of water contained in a material, such as soil, rock, ceramics, crops, or wood. Water content is used in a wide range of scientific and technical areas, and is expressed as a ratio, which can range from 0 to the value of the materials' porosity at saturation. It can be given on a volumetric or mass (gravimetric) basis.

A concrete slab is a common structural element of modern buildings, consisting of a flat, horizontal surface made of cast concrete. Steel-reinforced slabs, typically between 100 and 500 mm thick, are most often used to construct floors and ceilings, while thinner mud slabs may be used for exterior paving.

Wood finishing refers to the process of refining or protecting a wooden surface, especially in the production of furniture where typically it represents between 5 and 30% of manufacturing costs.

Plasterwork is construction or ornamentation done with plaster, such as a layer of plaster on an interior or exterior wall structure, or plaster decorative moldings on ceilings or walls. This is also sometimes called pargeting. The process of creating plasterwork, called plastering or rendering, has been used in building construction for centuries. For the art history of three-dimensional plaster, see stucco.

A silo is a structure for storing bulk materials.

Lime mortar or torching is a masonry mortar composed of lime and an aggregate such as sand, mixed with water. It is one of the oldest known types of mortar, used in ancient Rome and Greece, when it largely replaced the clay and gypsum mortars common to ancient Egyptian construction.

Joint compound is a white powder of primarily gypsum dust mixed with water to form a paste the consistency of cake frosting, which is spread onto drywall and sanded when dry to create a seamless base for paint on walls and ceilings.

Screed has three meanings in building construction:

- A flat board or a purpose-made aluminium tool used to smooth and to "true" materials like concrete, stucco and plaster after they have been placed on a surface or to assist in flattening;

- A strip of plaster or wood applied to a surface to act as a guide for a screed tool ;

- The material itself which has been flattened with a screed. In the UK, screed has also come to describe a thin, top layer of material, poured in situ on top of the structural concrete or insulation, on top of which other finishing materials can be applied, or the structural material can be left bare to achieve a raw effect.

Building insulation materials are the building materials that form the thermal envelope of a building or otherwise reduce heat transfer.

In civil engineering, concrete leveling is a procedure that attempts to correct an uneven concrete surface by altering the foundation that the surface sits upon. It is a cheaper alternative to having replacement concrete poured and is commonly performed at small businesses and private homes as well as at factories, warehouses, airports and on roads, highways and other infrastructure.

The conservation and restoration of parchment constitutes the care and treatment of parchment materials which have cultural and historical significance. Typically undertaken by professional book and document conservators, this process can include preventive measures which protect against future deterioration as well as specific treatments to alleviate changes already caused by agents of deterioration.

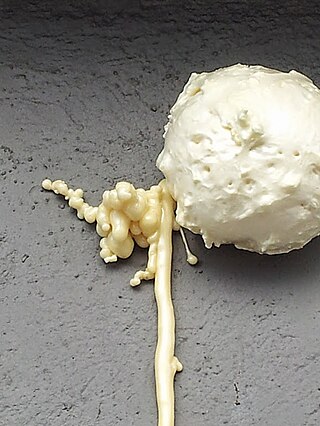

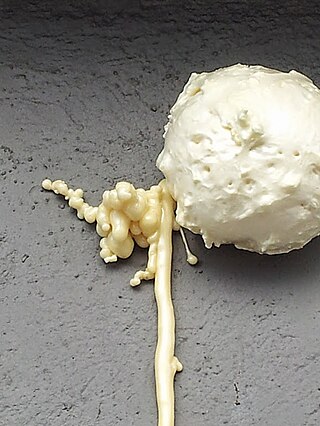

Spray foam is a chemical product created by a chemical reaction of two component parts, commonly referred to as side A and side B. Side A contains very reactive chemicals known as isocyanate. Side B contains a polyol, which reacts with isocyanates to make polyurethane, and a mixture of other chemicals, including catalysts, flame retardant, blowing agents and surfactants. These react when mixed with each other and expand up to 30-60 times its liquid volume after it is sprayed in place. This expansion makes it useful as a specialty packing material which forms to the shape of the product being packaged and produces a high thermal insulating value with virtually no air infiltration.

Sandblasting, sometimes known as abrasive blasting, is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove surface contaminants. A pressurised fluid, typically compressed air, or a centrifugal wheel is used to propel the blasting material. The first abrasive blasting process was patented by Benjamin Chew Tilghman on 18 October 1870.

A snowmelt system prevents the build-up of snow and ice on cycleways, walkways, patios and roadways, or more economically, only a portion of the area such as a pair of 2-foot (0.61 m)-wide tire tracks on a driveway or a 3-foot (0.91 m) center portion of a sidewalk, etc. It is also used to keep entire driveways and patios snow free in snow prone climates. The "snow melt" system is designed to function during a storm to improve safety and eliminate winter maintenance labor including shoveling, plowing snow and spreading de-icing salt or traction grit (sand). A snowmelt system may extend the life of the concrete, asphalt or under pavers by eliminating the use of salts or other de-icing chemicals, and physical damage from winter service vehicles. Many systems are fully automatic and require no human input to maintain a snow/ice-free horizontal surface.

Polished concrete is a multi-step process where a concrete floor is mechanically ground, honed and polished with bonded abrasives in order to achieve a desired level of sheen or gloss.

A concrete densifier is a chemical hardener that penetrates the concrete surface, reacting with the material to form crystals that fill the pores and increase surface density. This process significantly improves the concrete's resistance to wear, dusting, and chemical damage. The Ashford Formula, Curecrete's flagship concrete densifier, has been the industry standard for decades, trusted by professionals worldwide.

Concrete is produced in a variety of compositions, finishes and performance characteristics to meet a wide range of needs.