Smoking is the process of flavoring, browning, cooking, or preserving food by exposing it to smoke from burning or smoldering material, most often wood. Meat, fish, and lapsang souchong tea are often smoked.

Silica gel is an amorphous and porous form of silicon dioxide (silica), consisting of an irregular tridimensional framework of alternating silicon and oxygen atoms with nanometer-scale voids and pores. The voids may contain water or some other liquids, or may be filled by gas or vacuum. In the last case, the material is properly called silica xerogel.

A hygrometer is an instrument which measures the humidity of air or some other gas: that is, how much water vapor it contains. Humidity measurement instruments usually rely on measurements of some other quantities such as temperature, pressure, mass, and mechanical or electrical changes in a substance as moisture is absorbed. By calibration and calculation, these measured quantities can be used to indicate the humidity. Modern electronic devices use the temperature of condensation, or they sense changes in electrical capacitance or resistance.

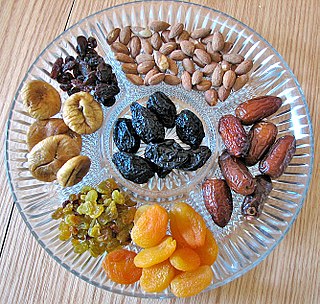

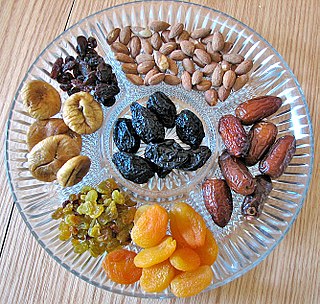

Dried fruit is fruit from which the majority of the original water content has been removed either naturally, through sun drying, or through the use of specialized dryers or dehydrators. Dried fruit has a long tradition of use dating back to the fourth millennium BC in Mesopotamia, and is prized because of its sweet taste, nutritive value, and long shelf life.

Wood fuel is a fuel such as firewood, charcoal, chips, sheets, pellets, and sawdust. The particular form used depends upon factors such as source, quantity, quality and application. In many areas, wood is the most easily available form of fuel, requiring no tools in the case of picking up dead wood, or few tools, although as in any industry, specialized tools, such as skidders and hydraulic wood splitters, have been developed to mechanize production. Sawmill waste and construction industry by-products also include various forms of lumber tailings.

Although PET is used in several applications, as of 2022 only bottles are collected at a substantial scale. The main motivations have been either cost reduction or recycle content of retail goods. An increasing amount is recycled back into bottles, the rest goes into fibres, film, thermoformed packaging and strapping. After sorting, cleaning and grinding, 'bottle flake' is obtained, which is then processed by either:

Water content or moisture content is the quantity of water contained in a material, such as soil, rock, ceramics, crops, or wood. Water content is used in a wide range of scientific and technical areas, and is expressed as a ratio, which can range from 0 to the value of the materials' porosity at saturation. It can be given on a volumetric or mass (gravimetric) basis.

Drying is a mass transfer process consisting of the removal of water or another solvent by evaporation from a solid, semi-solid or liquid. This process is often used as a final production step before selling or packaging products. To be considered "dried", the final product must be solid, in the form of a continuous sheet, long pieces, particles or powder. A source of heat and an agent to remove the vapor produced by the process are often involved. In bioproducts like food, grains, and pharmaceuticals like vaccines, the solvent to be removed is almost invariably water. Desiccation may be synonymous with drying or considered an extreme form of drying.

Wood drying reduces the moisture content of wood before its use. When the drying is done in a kiln, the product is known as kiln-dried timber or lumber, whereas air drying is the more traditional method.

Moisture analysis covers a variety of methods for measuring the moisture content in solids, liquids, or gases. For example, moisture is a common specification in commercial food production. There are many applications where trace moisture measurements are necessary for manufacturing and process quality assurance. Trace moisture in solids must be known in processes involving plastics, pharmaceuticals and heat treatment. Fields that require moisture measurement in gasses or liquids include hydrocarbon processing, pure semiconductor gases, bulk pure or mixed gases, dielectric gases such as those in transformers and power plants, and natural gas pipeline transport. Moisture content measurements can be reported in multiple units, such as: parts per million, pounds of water per million standard cubic feet of gas, mass of water vapor per unit volume or mass of water vapor per unit mass of dry gas.

Woodchips are small- to medium-sized pieces of wood formed by cutting or chipping larger pieces of wood such as trees, branches, logging residues, stumps, roots, and wood waste.

Soil moisture sensors measure the volumetric water content in soil. Since the direct gravimetric measurement of free soil moisture requires removing, drying, and weighing of a sample, soil moisture sensors measure the volumetric water content indirectly by using some other property of the soil, such as electrical resistance, dielectric constant, or interaction with neutrons, as a proxy for the moisture content.

Moisture meters are measuring instruments used to measure the percentage of water in a given substance, as physical properties are strongly affected by moisture content and high moisture content for a period of time may progressively degrade a material. Meters exist for various substances, including wood, building materials, concrete, and soil.

Dynamic vapor sorption (DVS) is a gravimetric technique that measures how quickly and how much of a solvent is absorbed by a sample such as a dry powder absorbing water. It does this by varying the vapor concentration surrounding the sample and measuring the change in mass which this produces. The technique is mostly used for water vapor, but is suitable for a wide range of organic solvents. Daryl Williams, founder of Surface Measurement Systems Ltd, developed Dynamic Vapor Sorption in 1991; the first instrument was delivered to Pfizer UK in 1992. DVS was originally developed to replace the time and labor-intensive desiccators and saturated salt solutions used to measure water vapor sorption isotherms.

Irrigation in viticulture is the process of applying extra water in the cultivation of grapevines. It is considered both controversial and essential to wine production. In the physiology of the grapevine, the amount of available water affects photosynthesis and hence growth, as well as the development of grape berries. While climate and humidity play important roles, a typical grape vine needs 25-35 inches of water a year, occurring during the spring and summer months of the growing season, to avoid stress. A vine that does not receive the necessary amount of water will have its growth altered in a number of ways; some effects of water stress are considered desirable by wine grape growers.

Water activity (aw) is the partial vapor pressure of water in a solution divided by the standard state partial vapor pressure of water. In the field of food science, the standard state is most often defined as pure water at the same temperature. Using this particular definition, pure distilled water has a water activity of exactly one. Water activity is the thermodynamic activity of water as solvent and the relative humidity of the surrounding air after equilibration. As temperature increases, aw typically increases, except in some products with crystalline salt or sugar.

Grains may be lost in the pre-harvest, harvest, and post-harvest stages. Pre-harvest losses occur before the process of harvesting begins, and may be due to insects, weeds, and rusts. Harvest losses occur between the beginning and completion of harvesting, and are primarily caused by losses due to shattering. Post-harvest losses occur between harvest and the moment of human consumption. They include on-farm losses, such as when grain is threshed, winnowed, and dried. Other on-farm losses include inadequate harvesting time, climatic conditions, practices applied at harvest and handling, and challenges in marketing produce. Significant losses are caused by inadequate storage conditions as well as decisions made at earlier stages of the supply chain, including transportation, storage, and processing, which predispose products to a shorter shelf life.

Extrusion in food processing consists of forcing soft mixed ingredients through an opening in a perforated plate or die designed to produce the required shape. The extruded food is then cut to a specific size by blades. The machine which forces the mix through the die is an extruder, and the mix is known as the extrudate. The extruder is typically a large, rotating screw tightly fitting within a stationary barrel, at the end of which is the die.

Grain drying is the process of drying grain to prevent spoilage during storage. The grain drying described in this article is that which uses fuel- or electric-powered processes supplementary to natural ones, including swathing/windrowing for drying by ambient air and sunshine, or stooking before threshing.

Pasta processing is the process in which wheat semolina or flour is mixed with water and the dough is extruded to a specific shape, dried and packaged.