Inline skates are a type of roller skate used for inline skating. Unlike typical roller skates, which have two front and two rear wheels, inline skates typically have two to five wheels arranged in a single line. Some, especially those for recreation, have a rubber "stop" or "brake" block attached to the rear of one or occasionally both of the skates so that the skater can slow down or stop by leaning back on the foot with the brake skate.

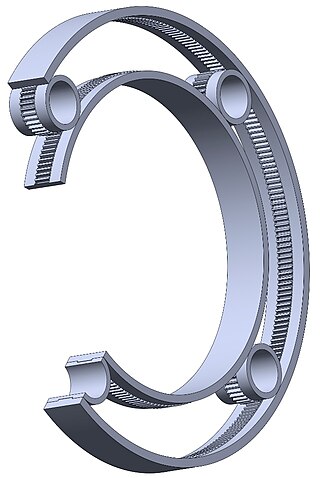

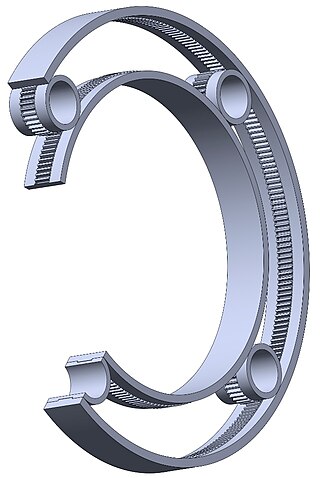

A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races.

Fluid bearings are bearings in which the load is supported by a thin layer of rapidly moving pressurized liquid or gas between the bearing surfaces. Since there is no contact between the moving parts, there is no sliding friction, allowing fluid bearings to have lower friction, wear and vibration than many other types of bearings. Thus, it is possible for some fluid bearings to have near-zero wear if operated correctly.

A bearing is a machine element that constrains relative motion to only the desired motion and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or the directions of the loads (forces) applied to the parts.

Inline speed skating is the roller sport of racing on inline skates. The sport may also be called inline racing, or speed skating by participants. Although it primarily evolved from racing on traditional roller skates, the sport is similar enough to ice speed skating that many competitors are known to switch between inline and ice speed skating according to the season.

A flexure bearing is a category of flexure which is engineered to be compliant in one or more angular degrees of freedom. Flexure bearings are often part of compliant mechanisms. Flexure bearings serve much of the same function as conventional bearings or hinges in applications which require angular compliance. However, flexures require no lubrication and exhibit very low or no friction.

In mechanical engineering, a rolling-element bearing, also known as a rolling bearing, is a bearing which carries a load by placing rolling elements between two concentric, grooved rings called races. The relative motion of the races causes the rolling elements to roll with very little rolling resistance and with little sliding.

A thrust bearing is a particular type of rotary bearing. Like other bearings they permanently rotate between parts, but they are designed to support a predominantly axial load.

Rolling is a type of motion that combines rotation and translation of that object with respect to a surface, such that, if ideal conditions exist, the two are in contact with each other without sliding.

Rolling resistance, sometimes called rolling friction or rolling drag, is the force resisting the motion when a body rolls on a surface. It is mainly caused by non-elastic effects; that is, not all the energy needed for deformation of the wheel, roadbed, etc., is recovered when the pressure is removed. Two forms of this are hysteresis losses, and permanent (plastic) deformation of the object or the surface. Note that the slippage between the wheel and the surface also results in energy dissipation. Although some researchers have included this term in rolling resistance, some suggest that this dissipation term should be treated separately from rolling resistance because it is due to the applied torque to the wheel and the resultant slip between the wheel and ground, which is called slip loss or slip resistance. In addition, only the so-called slip resistance involves friction, therefore the name "rolling friction" is to an extent a misnomer.

Chain drive is a way of transmitting mechanical power from one place to another. It is often used to convey power to the wheels of a vehicle, particularly bicycles and motorcycles. It is also used in a wide variety of machines besides vehicles.

Tapered roller bearings are rolling element bearings that can support axial forces as well as radial forces.

A needle roller bearing is a special type of roller bearing which uses long, thin cylindrical rollers resembling needles. Ordinary roller bearings' rollers are only slightly longer than their diameter, but needle bearings typically have rollers that are at least four times longer than their diameter. Like all bearings, they are used to reduce the friction of a rotating surface.

A linear-motion bearing or linear slide is a bearing designed to provide free motion in one direction. There are many different types of linear motion bearings.

A spherical bearing is a bearing that permits rotation about a central point in two orthogonal directions. Typically these bearings support a rotating shaft in the bore of the inner ring that must move not only rotationally, but also at an angle. It can either be a plain bearing or roller bearing.

Rolamite is a technology for very low friction bearings developed by Sandia National Laboratories in the 1960s. It is the only elementary machine discovered in the twentieth century and can be used in various ways such as a component in switches, thermostats, valves, pumps, and clutches, among others.

A mechanical watch is a watch that uses a clockwork mechanism to measure the passage of time, as opposed to quartz watches which function using the vibration modes of a piezoelectric quartz tuning fork, or radio watches, which are quartz watches synchronized to an atomic clock via radio waves. A mechanical watch is driven by a mainspring which must be wound either periodically by hand or via a self-winding mechanism. Its force is transmitted through a series of gears to power the balance wheel, a weighted wheel which oscillates back and forth at a constant rate. A device called an escapement releases the watch's wheels to move forward a small amount with each swing of the balance wheel, moving the watch's hands forward at a constant rate. The escapement is what makes the 'ticking' sound which is heard in an operating mechanical watch. Mechanical watches evolved in Europe in the 17th century from spring powered clocks, which appeared in the 15th century.

A slewing bearing or slew[ing] ring is a rotational rolling-element bearing that typically supports a heavy but slow-turning or slowly-oscillating loads in combination, often a horizontal platform such as a conventional crane, a swing yarder, or the wind-facing platform of a horizontal-axis (yaw) windmill. In other orientations they are used in materials handling grapples, forklift attachments, welding turnover jigs and so on.

A spherical roller bearing is a rolling-element bearing that permits rotation with low friction, and permits angular misalignment. Typically these bearings support a rotating shaft in the bore of the inner ring that may be misaligned in respect to the outer ring. The misalignment is possible due to the spherical internal shape of the outer ring and spherical rollers. Despite what their name may imply, spherical roller bearings are not truly spherical in shape. The rolling elements of spherical roller bearings are mainly cylindrical in shape, but have a profile that makes them appear like cylinders that have been slightly over-inflated.

A gear bearing is a type of rolling-element bearing similar to an epicyclic gear. Gear bearings consist of a number of smaller 'satellite' gears which revolve around the center of the bearing along a track on the outsides of the internal and satellite gears, and on the inside of the external gear. Each gear is in between two concentric rings. Therefore, the widths of the satellite gears must all be the same.