Related Research Articles

Cast iron is a class of iron–carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured; white cast iron has carbide impurities which allow cracks to pass straight through, grey cast iron has graphite flakes which deflect a passing crack and initiate countless new cracks as the material breaks, and ductile cast iron has spherical graphite "nodules" which stop the crack from further progressing.

John "Iron-Mad" Wilkinson was an English industrialist who pioneered the manufacture of cast iron and the use of cast-iron goods during the Industrial Revolution. He was the inventor of a precision boring machine that could bore cast iron cylinders, such as cannon barrels and piston cylinders used in the steam engines of James Watt. His boring machine has been called the first machine tool. He also developed a blowing device for blast furnaces that allowed higher temperatures, increasing their efficiency, and helped sponsor the first iron bridge in Coalbrookdale. He is notable for his method of cannon boring, his techniques at casting iron and his work with the government of France to establish a cannon foundry.

Dudd (Dud) Dudley (1600–1684) was an English metallurgist, who fought on the Royalist side in the English Civil War as a soldier, military engineer, and supplier of munitions. He was one of the first Englishmen to smelt iron ore using coke.

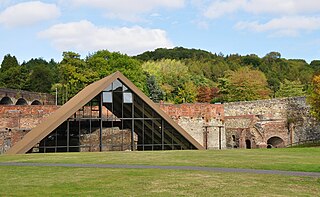

Coalbrookdale is a village in the Ironbridge Gorge in Shropshire, England, containing a settlement of great significance in the history of iron ore smelting. It lies within the civil parish called the Gorge.

Oakengates is a constituent town and civil parish in Telford and Wrekin, Shropshire, England. The towns parish population was recorded as 8,517 in the 2001 census.

The Madeley Wood Company was formed in 1756 when the Madeley Wood Furnaces, also called Bedlam Furnaces, were built beside the River Severn, one mile west of Blists Hill.

Abraham Darby III was an English ironmaster and Quaker. He was the third man of that name in several generations of an English Quaker family that played a pivotal role in the Industrial Revolution.

Abraham Darby, in his later life called Abraham Darby the Elder, now sometimes known for convenience as Abraham Darby I, was an English ironmaster and foundryman. Born into an English Quaker family that played an important role in the Industrial Revolution, Darby developed a method of producing pig iron in a blast furnace fuelled by coke rather than charcoal. This was a major step forward in the production of iron as a raw material for the Industrial Revolution.

Abraham Darby, in his lifetime called Abraham Darby the Younger, referred to for convenience as Abraham Darby II was the second man of that name in an English Quaker family that played an important role in the early years of the Industrial Revolution.

Horsehay is a suburban village on the western outskirts of Dawley, which, along with several other towns and villages, now forms part of the new town of Telford in Shropshire, England. Horsehay lies in the Dawley Hamlets parish, and on the northern edge of the Ironbridge Gorge area.

An ironmaster is the manager, and usually owner, of a forge or blast furnace for the processing of iron. It is a term mainly associated with the period of the Industrial Revolution, especially in Great Britain.

The Brymbo Steel Works was a former large steelworks in the village of Brymbo near Wrexham, Wales. In operation between 1796 and 1990, it was significant on account of its founder, one of whose original blast furnace stacks remains on the site.

Philip Foley was the youngest of the three surviving sons of the British ironmaster Thomas Foley. His father transferred all his ironworks in the Midlands to him in 1668 and 1669 for £60,000. He also settled an estate at Prestwood near Stourbridge on him on his marriage, to which Philip added the manor of Kinver.

The Wilden Ironworks was an ironworks in Wilden, Worcestershire, England. It operated for many years and was acquired by the Baldwin family, ancestors of British Prime Minister Stanley Baldwin.

Sir Clement Clerke, 1st Baronet was an important English entrepreneur, whose greatest achievement was the application of the reverberatory furnace (cupola) to smelting lead and copper, and to remelting pig iron for foundry purposes.

Thomas Baylies was a Quaker ironmaster first in England, then in Massachusetts.

Resolution was an early beam engine, installed between 1781–1782 at Coalbrookdale as a water-returning engine to power the blast furnaces and ironworks there. It was one of the last water-returning engines to be constructed, before the rotative beam engine made this type of engine obsolete.

The Goldney family were a wealthy English merchant trading family, most associated with Wiltshire and latterly Bristol. Later branches of the family became the Goldney baronets.

Richard Reynolds was an ironmaster, a partner in the ironworks in Coalbrookdale, Shropshire, at a significant time in the history of iron production. He was a Quaker and philanthropist.

William Reynolds was an ironmaster and a partner in the ironworks in Coalbrookdale in Shropshire, England. He was interested in advances in science and industry, and invented the inclined plane for canals.

References

- ↑ R. G. Schafer (ed.), A selection from the Records of Philip Foley's Stour Valley Iron Works 1669–74 (Worcs. Hist. Soc., n.s. 9, 1978), 94–5 and passim.

- ↑ P. W. King, 'Sir Clement Clerke and the Adoption of Coal in Metallurgy' Trans. Newcomen Soc. 73(1) (2001–2), 40.

- ↑ R. A. Mott, 'Coalbrookdale in the early years' Trans. Shrops. Arch. Soc. 56 (1957–60), 82–93; N. Cox, 'Imagination and innovation of an industrial pioneer: The first Abraham Darby' Ind. Arch. Rev. 12(2) (1990), 131.