Teesside is a built-up area around the River Tees in North East England, split between County Durham and North Yorkshire. The area contains the towns of Middlesbrough, Stockton-on-Tees, Billingham, Redcar, Thornaby-on-Tees, and Ingleby Barwick. Teesside's economy was once dominated by heavy manufacturing until deindustrialisation in the latter half of the 20th century. Chemical production continues to contribute significantly to Teesside's economy.

John "Iron-Mad" Wilkinson was an English industrialist who pioneered the manufacture of cast iron and the use of cast-iron goods during the Industrial Revolution. He was the inventor of a precision boring machine that could bore cast iron cylinders, such as cannon barrels and piston cylinders used in the steam engines of James Watt. His boring machine has been called the first machine tool. He also developed a blowing device for blast furnaces that allowed higher temperatures, increasing their efficiency, and helped sponsor the first iron bridge in Coalbrookdale. He is notable for his method of cannon boring, his techniques at casting iron and his work with the government of France to establish a cannon foundry.

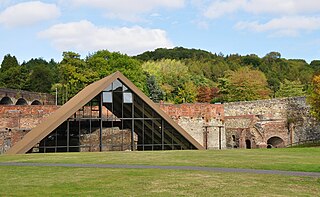

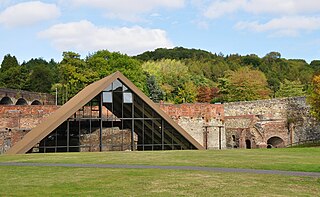

Coalbrookdale is a village in the Ironbridge Gorge and the Telford and Wrekin borough of Shropshire, England, containing a settlement of great significance in the history of iron ore smelting. It lies within the civil parish called the Gorge.

The Wealden iron industry was located in the Weald of south-eastern England. It was formerly an important industry, producing a large proportion of the bar iron made in England in the 16th century and most British cannon until about 1770. Ironmaking in the Weald used ironstone from various clay beds, and was fuelled by charcoal made from trees in the heavily wooded landscape. The industry in the Weald declined when ironmaking began to be fuelled by coke made from coal, which does not occur accessibly in the area.

Broseley is a market town in Shropshire, England, with a population of 4,929 at the 2011 Census and an estimate of 5,022 in 2019. The River Severn flows to its north and east. The first iron bridge in the world was built in 1779 across the Severn, linking Broseley with Coalbrookdale and Madeley. This contributed to the early industrial development in the Ironbridge Gorge, which is now part of a World Heritage Site.

Dorman Long & Co was a UK steel producer, later diversifying into bridge building. The company was once listed on the London Stock Exchange.

Abraham Darby, in his later life called Abraham Darby the Elder, now sometimes known for convenience as Abraham Darby I, was a British ironmaster and foundryman. Born into an English Quaker family that played an important role in the Industrial Revolution, Darby developed a method of producing pig iron in a blast furnace fuelled by coke rather than charcoal. This was a major step forward in the production of iron as a raw material for the Industrial Revolution.

Hopewell Furnace National Historic Site in southeastern Berks County, near Elverson, Pennsylvania, is an example of an American 19th century rural iron plantation, whose operations were based around a charcoal-fired cold-blast iron blast furnace. The significant restored structures include the furnace group (blast furnace, water wheel, blast machinery, cast house and charcoal house), as well as the ironmaster's house, a company store, the blacksmith's shop, a barn and several worker's houses.

The Brymbo Steel Works was a former large steelworks in the village of Brymbo near Wrexham, Wales. In operation between 1796 and 1990, it was significant on account of its founder, one of whose original blast furnace stacks remains on the site.

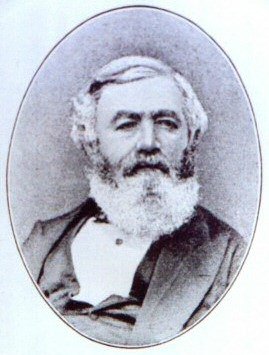

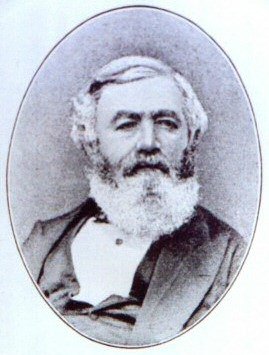

Henry William Ferdinand Bolckow, originally Heinrich Wilhelm Ferdinand Bölckow, was a Victorian industrialist and Member of Parliament, acknowledged as being one of the founders of modern Middlesbrough.

John Vaughan, known as Jacky, was born in Worcester on "St Thomas' Day" in 1799, the son of Welsh parents. He worked his way up the iron industry, becoming an ironmaster and co-founder of the largest of all the Victorian iron and steel companies, Bolckow Vaughan. Where Henry Bolckow provided the investment and business expertise, Vaughan contributed technical knowledge, in a long-lasting and successful partnership that transformed Middlesbrough from a small town to the centre of ironmaking in Britain.

The Teesside Steelworks was a large steelworks that formed a continuous stretch along the south bank of the River Tees from the towns of Middlesbrough to Redcar in North Yorkshire, England. At its height there were 91 blast furnaces within a 10-mile radius of the area. By the end of the 1970s there was only one left on Teesside. Opened in 1979 and located near the mouth of the River Tees, the Redcar blast furnace was the second largest in Europe.

Peter Grubb Jr. (1740–1786), Patriot and second son of Peter and Martha Bates Grubb, was a second-generation member of the Grubb Family Iron Dynasty along with his older brother Curtis Grubb. They operated the Cornwall Ironworks, making significant contributions to the American Revolutionary War effort.

The Warwick Furnace Farms is a historic district that is located in northern Chester County, Pennsylvania, United States that includes the ruins of an early iron furnace that was owned by Anna Rutter Nutt, widow of Samuel Nutt.

Losh, Wilson and Bell, later Bells, Goodman, then Bells, Lightfoot and finally Bell Brothers, was a leading Northeast England manufacturing company, founded in 1809 by the partners William Losh, Thomas Wilson, and Thomas Bell.

Bolckow, Vaughan & Co., Ltd was an English ironmaking and mining company founded in 1864, based on the partnership since 1840 of its two founders, Henry Bolckow and John Vaughan. The firm drove the dramatic growth of Middlesbrough and the production of coal and iron in the north-east of England in the 19th century. The two founding partners had an exceptionally close working relationship which lasted until Vaughan's death.

The Reading Furnace Historic District is a national historic district that is located in Warwick Township and East Nantmeal Township, Chester County, Pennsylvania.

Captain Samuel Van Leer was a military officer from Pennsylvania who served as a captain in the Continental Army during the American Revolutionary War and as a lieutenant in the Chester County Light Horse Volunteers from 1781 to 1785. After his retirement from the military, he owned the Reading Furnace ironworks.

Anthony Wayne Van Leer was an American ironmaster and owner of the Cumberland Furnace in Dickson County, Tennessee. He was a member of the influential Van Leer family, the son of Samuel Van Leer, captain in the Continental Army during the American Revolutionary War and nephew of General Anthony Wayne. The town of Vanleer, Tennessee is named after him.

Isaac Van Leer was a Pennsylvania ironmaster and owned the Hibernia Furnace, Springton Forge and historic Hibernia House in West Caln Township, Pennsylvania. He was a member of the influential Van Leer family and was the son of Samuel Van Leer, a captain in the Continental Army during the American Revolutionary War.