A screwdriver is a tool, manual or powered, used for driving screws. A typical simple screwdriver has a handle and a shaft, ending in a tip the user puts into the screw head before turning the handle. This form of the screwdriver has been replaced in many workplaces and homes with a more modern and versatile tool, a power drill, as they are quicker, easier, and also can drill holes. The shaft is usually made of tough steel to resist bending or twisting. The tip may be hardened to resist wear, treated with a dark tip coating for improved visual contrast between tip and screw—or ridged or treated for additional 'grip'. Handles are typically wood, metal, or plastic and usually hexagonal, square, or oval in cross-section to improve grip and prevent the tool from rolling when set down. Some manual screwdrivers have interchangeable tips that fit into a socket on the end of the shaft and are held in mechanically or magnetically. These often have a hollow handle that contains various types and sizes of tips, and a reversible ratchet action that allows multiple full turns without repositioning the tip or the user's hand.

A torque wrench is a tool used to apply a specific torque to a fastener such as a nut, bolt, or lag screw. It is usually in the form of a socket wrench with special internal mechanisms.

A drill string on a drilling rig is a column, or string, of drill pipe that transmits drilling fluid and torque to the drill bit. The term is loosely applied to the assembled collection of the smuggler pool, drill collars, tools and drill bit. The drill string is hollow so that drilling fluid can be pumped down through it and circulated back up the annulus.

Bolted joints are one of the most common elements in construction and machine design. They consist of fasteners that capture and join other parts, and are secured with the mating of screw threads.

A socket wrench is a type of spanner, that uses a closedsocket format, rather than a typical open wrench/spanner to turn a fastener, typically in the form of a nut or bolt.

A hose clamp is a device used to attach and seal a hose onto a fitting such as a barb or nipple.

A collet is a subtype of chuck that forms a collar around an object to be held and exerts a strong clamping force on the object when it is tightened, usually by means of a tapered outer collar. It may be used to hold a workpiece or a tool.

A chuck is a specialized type of clamp used to hold an object with radial symmetry, especially a cylinder. In a drill or a mill, a chuck holds the rotating tool; in a lathe, it holds the rotating workpiece.

A machine taper is a system for securing cutting tools or toolholders in the spindle of a machine tool or power tool. A male member of conical form fits into the female socket, which has a matching taper of equal angle.

A set screw, also known as a blind screw or a grub screw, is a type of screw generally used as a detent to secure an object within or against another object, usually without using a nut. The most common examples are securing a pulley or gear to a shaft. Set screws are usually headless, meaning that the screw is fully threaded and has no head projecting past the thread's major diameter. If a set screw does have a head, the thread will extend all the way to the head. A set screw is almost always driven with an internal-wrenching drive, such as a hex socket (Allen), star (Torx), square socket (Robertson), or a slot. The set screw passes through a threaded hole in the outer object and is tightened against the inner object to prevent it from moving relative to the outer object. It exerts compressional or clamping force through the bottom tip that projects through the hole.

A jackscrew, or screw jack, is a type of jack that is operated by turning a leadscrew. It is commonly used to lift moderately and heavy weights, such as vehicles; to raise and lower the horizontal stabilizers of aircraft; and as adjustable supports for heavy loads, such as the foundations of houses.

A metal lathe or metalworking lathe is a large class of lathes designed for precisely machining relatively hard materials. They were originally designed to machine metals; however, with the advent of plastics and other materials, and with their inherent versatility, they are used in a wide range of applications, and a broad range of materials. In machining jargon, where the larger context is already understood, they are usually simply called lathes, or else referred to by more-specific subtype names. These rigid machine tools remove material from a rotating workpiece via the movements of various cutting tools, such as tool bits and drill bits.

A C-clamp or G-clamp or G-cramp is a type of clamp device typically used to hold a wood or metal work piece, and often used in, but are not limited to, carpentry and welding. Often believed that these clamps are called "C" clamps because of their C-shaped frame, or also often called C-clamps or G-clamps because including the screw part, they are shaped like an uppercase letter G. However, in fact, they were originally called a carriage maker's clamp, or Carriage Clamp.

A screw is a mechanism that converts rotational motion to linear motion, and a torque to a linear force. It is one of the six classical simple machines. The most common form consists of a cylindrical shaft with helical grooves or ridges called threads around the outside. The screw passes through a hole in another object or medium, with threads on the inside of the hole that mesh with the screw's threads. When the shaft of the screw is rotated relative to the stationary threads, the screw moves along its axis relative to the medium surrounding it; for example rotating a wood screw forces it into wood. In screw mechanisms, either the screw shaft can rotate through a threaded hole in a stationary object, or a threaded collar such as a nut can rotate around a stationary screw shaft. Geometrically, a screw can be viewed as a narrow inclined plane wrapped around a cylinder.

A sex bolt,, is a type of fastener (nut) that has a barrel-shaped flange and protruding boss that is internally threaded. The bolts sits within the components being fastened, the flange provides the bearing surface. The sex bolt and accompanying machine screw sit flush on either side of the surfaces being fastened. It is normally chosen because of its low profile compared to other nuts. The sex bolt often has a built-in feature, such as a slot, to aid in tightening the fastener. Some sex bolts, more commonly known as "architectural bolts", have knurled barrels to allow one-sided assembly. "Binding posts" are similar to architectural bolts in that they are designed to be assembled from one side, but they have teeth on the flanged surface to keep them fixed.

The Meillerwagen was a German World War II trailer used to transport a V-2 rocket from the 'transloading point' of the Technical Troop Area to the launching point, to erect the missile on the Brennstand, and to act as the service gantry for fuelling and launch preparation.

In stagecraft, a c-clamp can refer to a number of different pieces of hardware, depending on its intended use.

A tripod head is the part of a tripod system that attaches the supported device to the tripod legs, and allows the orientation of the device to be manipulated or locked down. Modular or stand-alone tripod heads can be used on a wide range of tripods, allowing the user to choose which type of head best suits their needs. Integrated heads are built directly onto the tripod legs, reducing the cost of the tripod system.

A bolt is a form of threaded fastener with an external male thread requiring a matching pre-formed female thread such as a nut. Bolts are very closely related to screws.

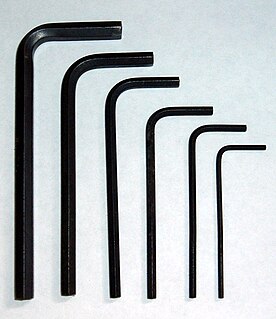

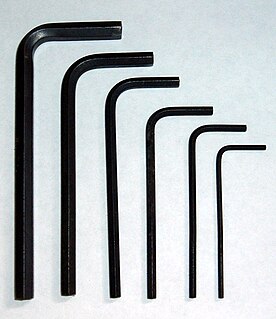

A hex key is a simple driver for screws that have heads with internal hexagonal recesses (sockets).