A truss is an assembly of members such as beams, connected by nodes, that creates a rigid structure.

A beam is a structural element that primarily resists loads applied laterally across the beam's axis. Its mode of deflection is primarily by bending, as loads produce reaction forces at the beam's support points and internal bending moments, shear, stresses, strains, and deflections. Beams are characterized by their manner of support, profile, equilibrium conditions, length, and material.

A hollow structural section (HSS) is a type of metal profile with a hollow cross section. The term is used predominantly in the United States, or other countries which follow US construction or engineering terminology.

A plate girder bridge is a bridge supported by two or more plate girders.

An I-beam is any of various structural members with an Ɪ- or H-shaped cross-section. Technical terms for similar items include H-beam, I-profile, universal column (UC), w-beam, universal beam (UB), rolled steel joist (RSJ), or double-T. I-beams are typically made of structural steel and serve a wide variety of construction uses.

Steel frame is a building technique with a "skeleton frame" of vertical steel columns and horizontal I-beams, constructed in a rectangular grid to support the floors, roof and walls of a building which are all attached to the frame. The development of this technique made the construction of the skyscraper possible. Steel frame has displaced its predecessor, the iron frame, in the early 20th century.

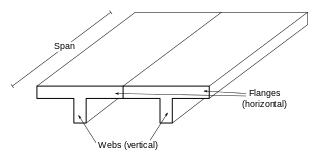

A girder is a beam used in construction. It is the main horizontal support of a structure which supports smaller beams. Girders often have an I-beam cross section composed of two load-bearing flanges separated by a stabilizing web, but may also have a box shape, Z shape, or other forms. Girders are commonly used to build bridges.

A purlin is a longitudinal, horizontal, structural member in a roof. In traditional timber framing there are three basic types of purlin: purlin plate, principal purlin, and common purlin.

Structural steel is a category of steel used for making construction materials in a variety of shapes. Many structural steel shapes take the form of an elongated beam having a profile of a specific cross section. Structural steel shapes, sizes, chemical composition, mechanical properties such as strengths, storage practices, etc., are regulated by standards in most industrialized countries.

A girder bridge is a bridge that uses girders as the means of supporting its deck. The two most common types of modern steel girder bridges are plate and box.

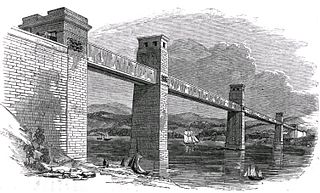

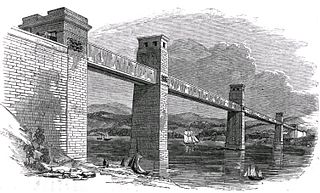

A box girder or tubular girder is a girder that forms an enclosed tube with multiple walls, as opposed to an Ɪ- or H-beam. Originally constructed of wrought iron joined by riveting, they are now made of rolled or welded steel, aluminium extrusions or prestressed concrete.

The rail profile is the cross sectional shape of a railway rail, perpendicular to its length.

A vehicle frame, also historically known as its chassis, is the main supporting structure of a motor vehicle to which all other components are attached, comparable to the skeleton of an organism.

Section modulus is a geometric property of a given cross-section used in the design of beams or flexural members. Other geometric properties used in design include: area for tension and shear, radius of gyration for compression, and second moment of area and polar second moment of area for stiffness. Any relationship between these properties is highly dependent on the shape in question. There are two types of section modulus, elastic and plastic:

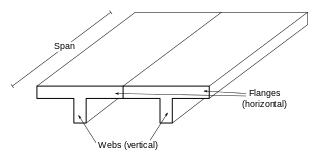

A T-beam, used in construction, is a load-bearing structure of reinforced concrete, wood or metal, with a capital 'T'-shaped cross section. The top of the T-shaped cross section serves as a flange or compression member in resisting compressive stresses. The web of the beam below the compression flange serves to resist shear stress. When used for highway bridges the beam incorporates reinforcing bars in the bottom of the beam to resist the tensile stresses which occur during bending.

Cold-formed steel (CFS) is the common term for steel products shaped by cold-working processes carried out near room temperature, such as rolling, pressing, stamping, bending, etc. Stock bars and sheets of cold-rolled steel (CRS) are commonly used in all areas of manufacturing. The terms are opposed to hot-formed steel and hot-rolled steel.

A bolt is an externally helical threaded fastener capable of being tightened or released by a twisting force (torque) to a matching nut. The bolt has an external male thread requiring a matching nut with a pre-formed female thread.

A balloon flange girder is a form of vertical I-beam wrought iron plate girder, where the top flange, instead of being a simple flat plate, is extended into a hollow tube. When a girder is subjected to a positive bending moment the top flange acts in compression making a flat plate flange more susceptible to local buckling than the balloon flange is.

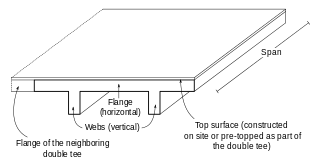

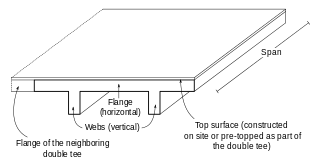

A double tee or double-T beam is a load-bearing structure that resembles two T-beams connected to each other side by side. The strong bond of the flange and the two webs creates a structure that is capable of withstanding high loads while having a long span. The typical sizes of double tees are up to 15 feet (4.6 m) for flange width, up to 5 feet (1.5 m) for web depth, and up to 80 feet (24 m) or more for span length. Double tees are pre-manufactured from prestressed concrete which allows construction time to be shortened.

This glossary of structural engineering terms pertains specifically to structural engineering and its sub-disciplines. Please see glossary of engineering for a broad overview of the major concepts of engineering.