A column or pillar in architecture and structural engineering is a structural element that transmits, through compression, the weight of the structure above to other structural elements below. In other words, a column is a compression member. The term column applies especially to a large round support with a capital and a base or pedestal, which is made of stone, or appearing to be so. A small wooden or metal support is typically called a post. Supports with a rectangular or other non-round section are usually called piers.

A truss is an assembly of members such as beams, connected by nodes, that creates a rigid structure.

A beam is a structural element that primarily resists loads applied laterally across the beam's axis. Its mode of deflection is primarily by bending, as loads produce reaction forces at the beam's support points and internal bending moments, shear, stresses, strains, and deflections. Beams are characterized by their manner of support, profile, equilibrium conditions, length, and material.

In structural engineering, buckling is the sudden change in shape (deformation) of a structural component under load, such as the bowing of a column under compression or the wrinkling of a plate under shear. If a structure is subjected to a gradually increasing load, when the load reaches a critical level, a member may suddenly change shape and the structure and component is said to have buckled. Euler's critical load and Johnson's parabolic formula are used to determine the buckling stress of a column.

A hollow structural section (HSS) is a type of metal profile with a hollow cross section. The term is used predominantly in the United States, or other countries which follow US construction or engineering terminology.

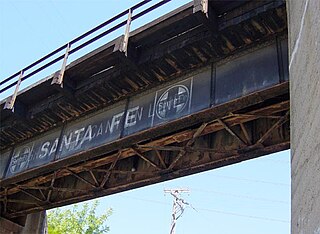

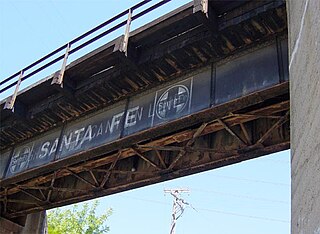

A plate girder bridge is a bridge supported by two or more plate girders.

Steel frame is a building technique with a "skeleton frame" of vertical steel columns and horizontal I-beams, constructed in a rectangular grid to support the floors, roof and walls of a building which are all attached to the frame. The development of this technique made the construction of the skyscraper possible. Steel frame has displaced its predecessor, the iron frame, in the early 20th century.

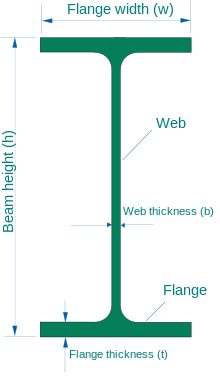

A girder is a beam used in construction. It is the main horizontal support of a structure which supports smaller beams. Girders often have an I-beam cross section composed of two load-bearing flanges separated by a stabilizing web, but may also have a box shape, Z shape, or other forms. Girders are commonly used to build bridges.

Specific modulus is a materials property consisting of the elastic modulus per mass density of a material. It is also known as the stiffness to weight ratio or specific stiffness. High specific modulus materials find wide application in aerospace applications where minimum structural weight is required. The dimensional analysis yields units of distance squared per time squared. The equation can be written as:

Structural steel is a category of steel used for making construction materials in a variety of shapes. Many structural steel shapes take the form of an elongated beam having a profile of a specific cross section. Structural steel shapes, sizes, chemical composition, mechanical properties such as strengths, storage practices, etc., are regulated by standards in most industrialized countries.

A girder bridge is a bridge that uses girders as the means of supporting its deck. The two most common types of modern steel girder bridges are plate and box.

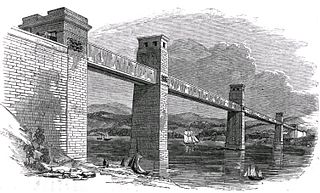

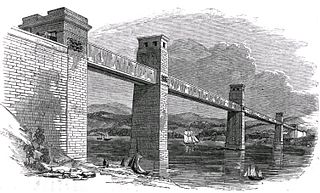

A box girder or tubular girder is a girder that forms an enclosed tube with multiple walls, as opposed to an I- or H-beam. Originally constructed of wrought iron joined by riveting, they are now made of rolled or welded steel, aluminium extrusions or prestressed concrete.

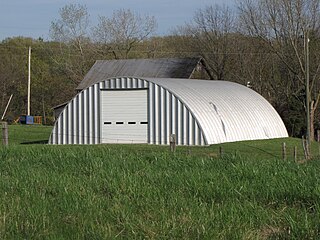

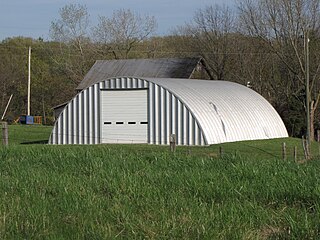

A steel building is a metal structure fabricated with steel for the internal support and for exterior cladding, as opposed to steel framed buildings which generally use other materials for floors, walls, and external envelope. Steel buildings are used for a variety of purposes including storage, work spaces and living accommodation. They are classified into specific types depending on how they are used.

Steel Design, or more specifically, Structural Steel Design, is an area of structural engineering used to design steel structures. These structures include schools, houses, bridges, commercial centers, tall buildings, warehouses, aircraft, ships and stadiums. The design and use of steel frames are commonly employed in the design of steel structures. More advanced structures include steel plates and shells.

Section modulus is a geometric property for a given cross-section used in the design of beams or flexural members. Other geometric properties used in design include area for tension and shear, radius of gyration for compression, and second moment of area and polar second moment of area for stiffness. Any relationship between these properties is highly dependent on the shape in question. Equations for the section moduli of common shapes are given below. There are two types of section moduli, the elastic section modulus and the plastic section modulus. The section moduli of different profiles can also be found as numerical values for common profiles in tables listing properties of such.

Cold-formed steel (CFS) is the common term for steel products shaped by cold-working processes carried out near room temperature, such as rolling, pressing, stamping, bending, etc. Stock bars and sheets of cold-rolled steel (CRS) are commonly used in all areas of manufacturing. The terms are opposed to hot-formed steel and hot-rolled steel.

Structural engineering depends upon a detailed knowledge of loads, physics and materials to understand and predict how structures support and resist self-weight and imposed loads. To apply the knowledge successfully structural engineers will need a detailed knowledge of mathematics and of relevant empirical and theoretical design codes. They will also need to know about the corrosion resistance of the materials and structures, especially when those structures are exposed to the external environment.

ASTM A992 steel is a structural steel alloy often used in the US for steel wide-flange and I beams. Like other carbon steels, the density of ASTM A992 steel is approximately 7850 kg/m3. ASTM A992 steel has the following minimum mechanical properties, according to ASTM specification A992/A992M. Tensile yield strength, 345 MPa (50 ksi); tensile ultimate strength, 450 MPa (65 ksi); strain to rupture in a 200-mm-long test specimen, 18%; strain to rupture in a 50-mm-long test specimen, 21%.

The structural channel, also known as a C-channel or Parallel Flange Channel (PFC), is a type of beam, used primarily in building construction and civil engineering. Its cross section consists of a wide "web", usually but not always oriented vertically, and two "flanges" at the top and bottom of the web, only sticking out on one side of the web. It is distinguished from I-beam or H-beam or W-beam type steel cross sections in that those have flanges on both sides of the web.

This glossary of structural engineering terms pertains specifically to structural engineering and its sub-disciplines. Please see glossary of engineering for a broad overview of the major concepts of engineering.