A flange is a protruded ridge, lip or rim, either external or internal, that serves to increase strength ; for easy attachment/transfer of contact force with another object ; or for stabilizing and guiding the movements of a machine or its parts. The term "flange" is also used for a kind of tool used to form flanges.

Rebar, known when massed as reinforcing steel or reinforcement steel, is a steel bar or mesh of steel wires used as a tension device in reinforced concrete and reinforced masonry structures to strengthen and aid the concrete under tension. Concrete is strong under compression, but has weak tensile strength. Rebar significantly increases the tensile strength of the structure. Rebar's surface is often "deformed" with ribs, lugs or indentations to promote a better bond with the concrete and reduce the risk of slippage.

A truss is an assembly of members such as beams, connected by nodes, that creates a rigid structure.

Seismic retrofitting is the modification of existing structures to make them more resistant to seismic activity, ground motion, or soil failure due to earthquakes. With better understanding of seismic demand on structures and with our recent experiences with large earthquakes near urban centers, the need of seismic retrofitting is well acknowledged. Prior to the introduction of modern seismic codes in the late 1960s for developed countries and late 1970s for many other parts of the world, many structures were designed without adequate detailing and reinforcement for seismic protection. In view of the imminent problem, various research work has been carried out. State-of-the-art technical guidelines for seismic assessment, retrofit and rehabilitation have been published around the world – such as the ASCE-SEI 41 and the New Zealand Society for Earthquake Engineering (NZSEE)'s guidelines. These codes must be regularly updated; the 1994 Northridge earthquake brought to light the brittleness of welded steel frames, for example.

Residual stresses are stresses that remain in a solid material after the original cause of the stresses has been removed. Residual stress may be desirable or undesirable. For example, laser peening imparts deep beneficial compressive residual stresses into metal components such as turbine engine fan blades, and it is used in toughened glass to allow for large, thin, crack- and scratch-resistant glass displays on smartphones. However, unintended residual stress in a designed structure may cause it to fail prematurely.

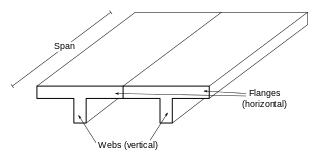

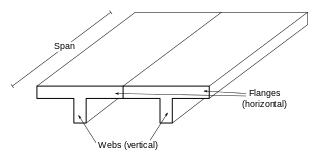

An I-beam, also known as H-beam, w-beam, universal beam (UB), rolled steel joist (RSJ), or double-T, is a beam with an I or H-shaped cross-section. The horizontal elements of the I are flanges, and the vertical element is the "web". I-beams are usually made of structural steel and are used in construction and civil engineering.

In structural engineering, a rigid frame is the load-resisting skeleton constructed with straight or curved members interconnected by mostly rigid connections, which resist movements induced at the joints of members. Its members can take bending moment, shear, and axial loads.

Anchor bolts are used to connect structural and non-structural elements to concrete. The connection can be made by a variety of different components: anchor bolts, steel plates, or stiffeners. Anchor bolts transfer different types of load: tension forces and shear forces.

Steel design, or more specifically, structural steel design, is an area of structural engineering used to design steel structures. These structures include schools, houses, bridges, commercial centers, tall buildings, warehouses, aircraft, ships and stadiums. The design and use of steel frames are commonly employed in the design of steel structures. More advanced structures include steel plates and shells.

Butt welding is when two pieces of metal are placed end-to-end without overlap and then welded along the joint. Importantly, in a butt joint, the surfaces of the workpieces being joined are on the same plane and the weld metal remains within the planes of the surfaces.

A steel plate shear wall (SPSW) consists of steel infill plates bounded by boundary elements.

A T-beam, used in construction, is a load-bearing structure of reinforced concrete, wood or metal, with a T-shaped cross section. The top of the T-shaped cross section serves as a flange or compression member in resisting compressive stresses. The web of the beam below the compression flange serves to resist shear stress and to provide greater separation for the coupled forces of bending.

Cold-formed steel (CFS) is the common term for steel products shaped by cold-working processes carried out near room temperature, such as rolling, pressing, stamping, bending, etc. Stock bars and sheets of cold-rolled steel (CRS) are commonly used in all areas of manufacturing. The terms are opposed to hot-formed steel and hot-rolled steel.

Process duct work conveys large volumes of hot, dusty air from processing equipment to mills, baghouses to other process equipment. Process duct work may be round or rectangular. Although round duct work costs more to fabricate than rectangular duct work, it requires fewer stiffeners and is favored in many applications over rectangular ductwork.

ASTM A992 steel is a structural steel alloy often used in the US for steel wide-flange and I beams. Like other carbon steels, the density of ASTM A992 steel is approximately 7850 kg/m3. ASTM A992 steel has the following minimum mechanical properties, according to ASTM specification A992/A992M. Tensile yield strength, 345 MPa (50 ksi); tensile ultimate strength, 450 MPa (65 ksi); strain to rupture in a 200-mm-long test specimen, 18%; strain to rupture in a 50-mm-long test specimen, 21%.

A buckling-restrained brace (BRB) is a structural brace in a building, designed to allow the building to withstand cyclical lateral loadings, typically earthquake-induced loading. It consists of a slender steel core, a concrete casing designed to continuously support the core and prevent buckling under axial compression, and an interface region that prevents undesired interactions between the two. Braced frames that use BRBs – known as buckling-restrained braced frames, or BRBFs – have significant advantages over typical braced frames.

The structural channel, also known as a C-channel or Parallel Flange Channel (PFC), is a type of beam, used primarily in building construction and civil engineering. Its cross section consists of a wide "web", usually but not always oriented vertically, and two "flanges" at the top and bottom of the web, only sticking out on one side of the web. It is distinguished from I-beam or H-beam or W-beam type steel cross sections in that those have flanges on both sides of the web.

This glossary of structural engineering terms pertains specifically to structural engineering and its sub-disciplines. Please see glossary of engineering for a broad overview of the major concepts of engineering.

Adhesive bonding is a process by which two members of equal or dissimilar composition are joined. It is used in place of, or to complement other joining methods such mechanical fasting by the use nails, rivets, screws or bolts and many welding processes. The use of adhesives provides many advantages over welding and mechanical fastening in steel construction; however, many challenges still exist that have made the use of adhesives in structural steel components very limited.

John William Fisher is a professor emeritus of civil engineering.