Structural engineering is a sub-discipline of civil engineering in which structural engineers are trained to design the 'bones and joints' that create the form and shape of human-made structures. Structural engineers also must understand and calculate the stability, strength, rigidity and earthquake-susceptibility of built structures for buildings and nonbuilding structures. The structural designs are integrated with those of other designers such as architects and building services engineer and often supervise the construction of projects by contractors on site. They can also be involved in the design of machinery, medical equipment, and vehicles where structural integrity affects functioning and safety. See glossary of structural engineering.

Limit State Design (LSD), also known as Load And Resistance Factor Design (LRFD), refers to a design method used in structural engineering. A limit state is a condition of a structure beyond which it no longer fulfills the relevant design criteria. The condition may refer to a degree of loading or other actions on the structure, while the criteria refer to structural integrity, fitness for use, durability or other design requirements. A structure designed by LSD is proportioned to sustain all actions likely to occur during its design life, and to remain fit for use, with an appropriate level of reliability for each limit state. Building codes based on LSD implicitly define the appropriate levels of reliability by their prescriptions.

In structural engineering, buckling is the sudden change in shape (deformation) of a structural component under load, such as the bowing of a column under compression or the wrinkling of a plate under shear. If a structure is subjected to a gradually increasing load, when the load reaches a critical level, a member may suddenly change shape and the structure and component is said to have buckled. Euler's critical load and Johnson's parabolic formula are used to determine the buckling stress of a column.

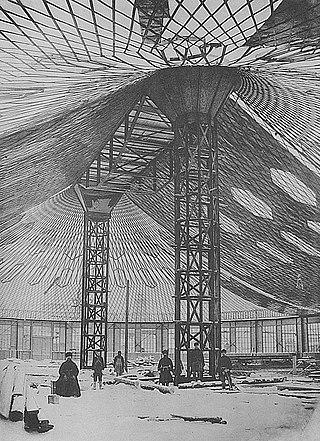

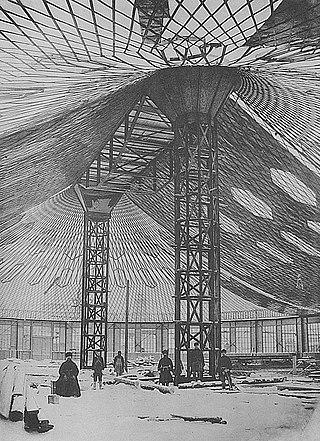

In structural engineering, a tensile structure is a construction of elements carrying only tension and no compression or bending. The term tensile should not be confused with tensegrity, which is a structural form with both tension and compression elements. Tensile structures are the most common type of thin-shell structures.

Permissible stress design is a design philosophy used by mechanical engineers and civil engineers.

An I-beam is any of various structural members with an Ɪ- or H-shaped cross-section. Technical terms for similar items include H-beam, I-profile, universal column (UC), w-beam, universal beam (UB), rolled steel joist (RSJ), or double-T. I-beams are typically made of structural steel and serve a wide variety of construction uses.

In structural engineering, a rigid frame is the load-resisting skeleton constructed with straight or curved members interconnected by predominantly rigid connections, which resist movements induced at the joints of members. Its members can resist bending moment, shear, and axial loads.

Structural steel is a category of steel used for making construction materials in a variety of shapes. Many structural steel shapes take the form of an elongated beam having a profile of a specific cross section. Structural steel shapes, sizes, chemical composition, mechanical properties such as strengths, storage practices, etc., are regulated by standards in most industrialized countries.

Portal frame is a construction technique where vertical supports are connected to horizontal beams or trusses via fixed joints with designed-in moment-resisting capacity. The result is wide spans and open floors.

A36 steel is a common structural steel alloy used in the United States. The A36 standard was established by the ASTM International. The standard was published in 1960 and has been updated several times since. Prior to 1960, the dominant standards for structural steel in North America were A7 and A9. Note that SAE/AISI A7 and A9 tool steels are not the same as the obsolete ASTM A7 and A9 structural steels.

Allowable Strength Design (ASD) is a term used by the American Institute of Steel Construction (AISC) in the 14th Edition of the Manual of Steel Construction.

In solid mechanics and structural engineering, section modulus is a geometric property of a given cross-section used in the design of beams or flexural members. Other geometric properties used in design include: area for tension and shear, radius of gyration for compression, and second moment of area and polar second moment of area for stiffness. Any relationship between these properties is highly dependent on the shape in question. There are two types of section modulus, elastic and plastic:

Tension members are structural elements that are subjected to axial tensile forces. Examples of tension members are bracing for buildings and bridges, truss members, and cables in suspended roof systems.

Cold-formed steel (CFS) is the common term for steel products shaped by cold-working processes carried out near room temperature, such as rolling, pressing, stamping, bending, etc. Stock bars and sheets of cold-rolled steel (CRS) are commonly used in all areas of manufacturing. The terms are opposed to hot-formed steel and hot-rolled steel.

Process duct work conveys large volumes of hot, dusty air from processing equipment to mills, baghouses to other process equipment. Process duct work may be round or rectangular. Although round duct work costs more to fabricate than rectangular duct work, it requires fewer stiffeners and is favored in many applications over rectangular ductwork.

Direct tension indicators, or DTIs, are single-use mechanical load cells used to indicate when the required tension has been achieved in structural fastener assemblies.

A buckling-restrained brace (BRB) is a structural brace in a building, designed to allow the building to withstand cyclical lateral loadings, typically earthquake-induced loading. It consists of a slender steel core, a concrete casing designed to continuously support the core and prevent buckling under axial compression, and an interface region that prevents undesired interactions between the two. Braced frames that use BRBs – known as buckling-restrained braced frames, or BRBFs – have significant advantages over typical braced frames.

SDC Verifier is a commercial finite element analysis post-processor software with a calculation core for checking structures according to different standards, either predefined or self programmed, and final report generation with all checks. The goal is to automate routine work and speed up a verification of the engineering projects. It works as an addon for popular FEA software Ansys, Femap and Simcenter 3D.

This glossary of structural engineering terms pertains specifically to structural engineering and its sub-disciplines. Please see Glossary of engineering for a broad overview of the major concepts of engineering.

Adhesive bonding is a process by which two members of equal or dissimilar composition are joined. It is used in place of, or to complement other joining methods such mechanical fasting by the use nails, rivets, screws or bolts and many welding processes. The use of adhesives provides many advantages over welding and mechanical fastening in steel construction; however, many challenges still exist that have made the use of adhesives in structural steel components very limited.