Corrugated fiberboard, corrugated cardboard, or corrugated is a type of packaging material consisting of a fluted corrugated sheet and one or two flat linerboards. It is made on "flute lamination machines" or "corrugators" and is used for making corrugated boxes. The corrugated medium sheet and the linerboard(s) are made of kraft containerboard, a paperboard material usually over 0.25 millimetres (0.01 in) thick.

A chisel is a wedged hand tool with a characteristically shaped cutting edge on the end of its blade, for carving or cutting a hard material. The tool can be used by hand, struck with a mallet, or applied with mechanical power. The handle and blade of some types of chisel are made of metal or wood with a sharp edge in it.

Metalworking is the process of shaping and reshaping metals in order to create useful objects, parts, assemblies, and large scale structures. As a term, it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges, down to precise engine parts and delicate jewelry.

A table saw is a woodworking tool, consisting of a circular saw blade, mounted on an arbor, that is driven by an electric motor. The drive mechanism is mounted below a table that provides support for the material, usually wood, being cut, with the blade protruding up through the table into the material.

Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing, which utilizes machine tools, in contrast to additive manufacturing, which uses controlled addition of material.

A file is a tool used to remove fine amounts of material from a workpiece. It is common in woodworking, metalworking, and other similar trade and hobby tasks. Most are hand tools, made of a case hardened steel bar of rectangular, square, triangular, or round cross-section, with one or more surfaces cut with sharp, generally parallel teeth. A narrow, pointed tang is common at one end, to which a handle may be fitted.

Drilling is a cutting process where a drill bit is spun to cut a hole of circular cross-section in solid materials. The drill bit is usually a rotary cutting tool, often multi-point. The bit is pressed against the work-piece and rotated at rates from hundreds to thousands of revolutions per minute. This forces the cutting edge against the work-piece, cutting off chips (swarf) from the hole as it is drilled.

A reamer is a type of rotary cutting tool used in metalworking. Precision reamers are designed to enlarge the size of a previously formed hole by a small amount but with a high degree of accuracy to leave smooth sides. There are also non-precision reamers which are used for more basic enlargement of holes or for removing burrs. The process of enlarging the hole is called reaming. There are many different types of reamer and they may be designed for use as a hand tool or in a machine tool, such as a milling machine or drill press.

A miter saw or mitre saw is a saw used to make accurate crosscuts and miters in a workpiece by positioning a mounted blade onto a board. A miter saw in its earliest form was composed of a back saw in a miter box, but in modern implementation consists of a powered circular saw that can be positioned at a variety of angles and lowered onto a board positioned against a backstop called the fence.

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process.

Grinding wheels are wheels that contain abrasive compounds for grinding and abrasive machining operations. Such wheels are also used in grinding machines.

Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates.

In machining, a metal lathe or metalworking lathe is a large class of lathes designed for precisely machining relatively hard materials. They were originally designed to machine metals; however, with the advent of plastics and other materials, and with their inherent versatility, they are used in a wide range of applications, and a broad range of materials. In machining jargon, where the larger context is already understood, they are usually simply called lathes, or else referred to by more-specific subtype names. These rigid machine tools remove material from a rotating workpiece via the movements of various cutting tools, such as tool bits and drill bits.

An end mill is a type of milling cutter, a cutting tool used in industrial milling applications. It is distinguished from the drill bit in its application, geometry, and manufacture. While a drill bit can only cut in the axial direction, most milling bits can cut in the radial direction. Not all mills can cut axially; those designed to cut axially are known as end mills.

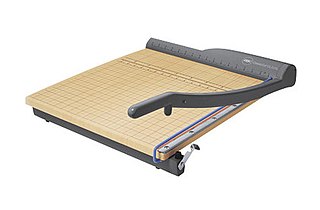

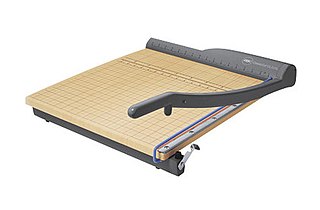

A paper cutter, also known as a paper guillotine or simply a guillotine, is a tool often found in offices and classrooms. It is designed to administer straight cuts to single sheets or large stacks of paper at once.

A core sample is a cylindrical section of (usually) a naturally-occurring substance. Most core samples are obtained by drilling with special drills into the substance, such as sediment or rock, with a hollow steel tube, called a core drill. The hole made for the core sample is called the "core hole". A variety of core samplers exist to sample different media under different conditions; there is continuing development in the technology. In the coring process, the sample is pushed more or less intact into the tube. Removed from the tube in the laboratory, it is inspected and analyzed by different techniques and equipment depending on the type of data desired.

Snips, also known as shears, are hand tools used to cut sheet metal and other tough webs. It is a cutting tool. Workers use various types of snips, with the cutting edges being straight or curved to various degrees. The style of edge employed will depend if a straight sheer or some type of shapes cut is necessary. There are two broad categories: tinner's snips, which are similar to common scissors, and compound-action snips, which use a compound leverage handle system to increase the mechanical advantage.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

Blanking and piercing are shearing processes in which a punch and die are used to produce parts from coil or sheet stock. Blanking produces the outside features of the component, while piercing produces internal holes or shapes. The web is created after multiple components have been produced and is considered scrap material. The "slugs" produced by piercing internal features are also considered scrap. The terms "piercing" and "punching" can be used interchangeably.

Drafting tools may be used for measurement and layout of drawings, or to improve the consistency and speed of creation of standard drawing elements. Tools such as pens and pencils mark the drawing medium. Other tools such as straight edges, assist the operator in drawing straight lines, or assist the operator in drawing complicated shapes repeatedly. Various scales and the protractor are used to measure the lengths of lines and angles, allowing accurate scale drawing to be carried out. The compass is used to draw arcs and circles. A drawing board was used to hold the drawing media in place; later boards included drafting machines that sped the layout of straight lines and angles. Tools such as templates and lettering guides assisted in the drawing of repetitive elements such as circles, ellipses, schematic symbols and text. Other auxiliary tools were used for special drawing purposes or for functions related to the preparation and revision of drawings. The tools used for manual technical drawing have been displaced by the advent of computer-aided drawing, drafting and design (CADD).