A circular saw or a buzz saw, is a power-saw using a toothed or abrasive disc or blade to cut different materials using a rotary motion spinning around an arbor. A hole saw and ring saw also use a rotary motion but are different from a circular saw. Circular saws may also be loosely used for the blade itself. Circular saws were invented in the late 18th century and were in common use in sawmills in the United States by the middle of the 19th century.

A saw is a tool consisting of a tough blade, wire, or chain with a hard toothed edge used to cut through material. Various terms are used to describe toothed and abrasive saws.

Portable sawmills are sawmills small enough to be moved easily and set up in the field. They have existed for over 100 years but grew in popularity in the United States starting in the 1970s, when the 1973 oil crisis and the back-to-the-land movement had led to renewed interest in small woodlots and in self-sufficiency. Their popularity has grown exponentially since 1982, when the portable bandsaw mill was first commercialized.

Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing, which utilizes machine tools, in contrast to additive manufacturing, which uses controlled addition of material.

A saw filer is a person who maintains and repairs saws in a saw mill. A saw filer's work area in the mill is called the filing room.

A bandsaw is a power saw with a long, sharp blade consisting of a continuous band of toothed metal stretched between two or more wheels to cut material. They are used principally in woodworking, metalworking, and lumbering, but may cut a variety of materials. Advantages include uniform cutting action as a result of an evenly distributed tooth load, and the ability to cut irregular or curved shapes like a jigsaw. The minimum radius of a curve is determined by the width of the band and its kerf. Most bandsaws have two wheels rotating in the same plane, one of which is powered, although some may have three or four to distribute the load. The blade itself can come in a variety of sizes and tooth pitches, which enables the machine to be highly versatile and able to cut a wide variety of materials including wood, metal and plastic. Band saw is recommended for use in cutting metal as it produces much less toxic fumes and particulates when compared with angle grinder and reciprocating saw.

A hacksaw is a fine-toothed saw, originally and mainly made for cutting metal. The equivalent saw for cutting wood is usually called a bow saw.

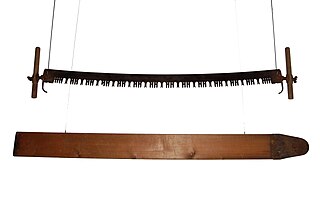

A crosscut saw is any saw designed for cutting wood perpendicular to (across) the wood grain. Crosscut saws may be small or large, with small teeth close together for fine work like woodworking or large for coarse work like log bucking, and can be a hand tool or power tool.

A miter saw or mitre saw is a saw used to make accurate crosscuts and miters in a workpiece by positioning a mounted blade onto a board. A miter saw in its earliest form was composed of a back saw in a miter box, but in modern implementation consists of a powered circular saw that can be positioned at a variety of angles and lowered onto a board positioned against a backstop called the fence.

A hole saw, also known as a hole cutter, is a saw blade of annular (ring) shape, whose annular kerf creates a hole in the workpiece without having to cut up the core material. It is used in a drill. Hole saws typically have a pilot drill bit (arbor) at their center to keep the saw teeth from walking. The fact that a hole saw creates the hole without needing to cut up the core often makes it preferable to twist drills or spade drills for relatively large holes (especially those larger than 25 millimetres. The same hole can be made faster and using less power.

The L. S. Starrett Company is an American manufacturer of tools and instruments used by machinists, tool and die makers, and the construction industry. The company was founded by businessman and inventor Laroy Sunderland Starrett in 1880. The company patented such items as the sliding combination square, bench vises, and a shoe hook fastener. It makes precision steel rules and tapes, calipers, micrometers, and dial indicators, among others. In addition, Starrett manufacturers a wide variety of saw products including bandsaws, hole saws, jigsaws, amongst other power tool accessories and cutting tools. More recently, they have expanded their high-end metrology equipment solutions including optical comparators, vision systems, laser measurement, force and material measurement testing.

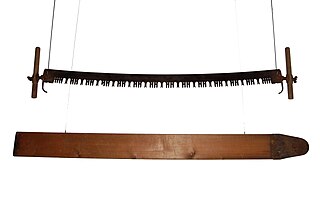

A wire saw is a saw that uses a metal wire or cable for mechanical cutting of bulk solid material such as stone, wood, glass, ferrites, concrete, metals, crystals etc.. Industrial wire saws are usually powered. There are also hand-powered survivalist wire saws suitable for cutting tree branches. Wire saws are classified as continuous or oscillating. Sometimes the wire itself is referred to as a "blade".

Stone veneer is a thin layer of any stone used as decorative facing material that is not meant to be load bearing. Stone cladding is a stone veneer, or simulated stone, applied to a building or other structure made of a material other than stone. Stone cladding is sometimes applied to concrete and steel buildings as part of their original architectural design.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

A surform tool features perforated sheet metal and resembles a food grater. A surform tool consists of a steel strip with holes punched out and the rim of each hole sharpened to form a cutting edge. The strip is mounted in a carriage or handle. Surform tools were called "cheese graters" decades before they entered the market as kitchen utensils used to grate cheese. Surform planes have been described as a cross between a rasp and a plane.

SawStop is an American table saw manufacturer headquartered in Tualatin, Oregon. The company was founded in 2000 to manufacture table saws that feature a patented automatic braking system that stops the blade upon contact with skin or flesh.

A jigsaw is a reciprocating saw that can cut irregular curves, such as stenciled designs, in wood, metal, or other materials.

'Shopsmith, Inc' is a US manufacturer of Shopsmith combination machines for woodworking. The brand has its origins in the ShopSmith 10ER launched in the late 1940s, an immediate success with do-it-yourself homeowners. Later the brand changed hands twice before becoming dormant in 1966. Shopsmith, Inc. was founded in 1972 to resume manufacture of ShopSmith parts and product with John R. Folkerth as the principal stockholder. In 2009 Shopsmith, Inc. went into bankruptcy, and reorganized as RLF Brands with his son Robert L. Folkerth as the owner. RLF sold the company in August 2023 to a new company also named Shopsmith, Inc. with Nicholas Cupps as the CEO and principal shareholder.

A swingblade sawmill utilizes a single circular sawblade which pivots about a 90 degree point, to saw in both vertical and horizontal planes. The single blade travels horizontally in one direction down the log, and returns in vertical position, thus removing a sawn piece of timber. The swingblade head unit is normally mounted on a moving frame that travels along a track or tracks, up and down a stationary log.

Republic Stamping and Enameling was an enamelware manufacturing company in Canton, Ohio. It operated from 1907 until 1952 when it was purchased by Ecko Products of Chicago. The company was founded by a group of investors led by Henry C. Milligan (1853–1940), an inventor who held several patents for improvements in enamelware manufacturing.