A calorimeter is an object used for calorimetry, or the process of measuring the heat of chemical reactions or physical changes as well as heat capacity. Differential scanning calorimeters, isothermal micro calorimeters, titration calorimeters and accelerated rate calorimeters are among the most common types. A simple calorimeter just consists of a thermometer attached to a metal container full of water suspended above a combustion chamber. It is one of the measurement devices used in the study of thermodynamics, chemistry, and biochemistry.

Humidity is the concentration of water vapor present in the air. Water vapor, the gaseous state of water, is generally invisible to the human eye. Humidity indicates the likelihood for precipitation, dew, or fog to be present.

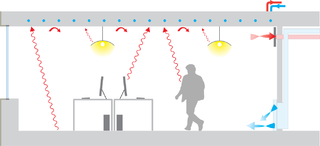

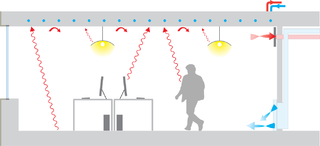

Heat transfer is a discipline of thermal engineering that concerns the generation, use, conversion, and exchange of thermal energy (heat) between physical systems. Heat transfer is classified into various mechanisms, such as thermal conduction, thermal convection, thermal radiation, and transfer of energy by phase changes. Engineers also consider the transfer of mass of differing chemical species, either cold or hot, to achieve heat transfer. While these mechanisms have distinct characteristics, they often occur simultaneously in the same system.

In the context of construction, the R-value is a measure of how well a two-dimensional barrier, such as a layer of insulation, a window or a complete wall or ceiling, resists the conductive flow of heat. R-value is the temperature difference per unit of heat flux needed to sustain one unit of heat flux between the warmer surface and colder surface of a barrier under steady-state conditions. The measure is therefore equally relevant for lowering energy bills for heating in the winter, for cooling in the summer, and for general comfort.

A hygrometer is an instrument which measures the humidity of air or some other gas: that is, how much water vapor it contains. Humidity measurement instruments usually rely on measurements of some other quantities such as temperature, pressure, mass, a mechanical or electrical change in a substance as moisture is absorbed. By calibration and calculation, these measured quantities can lead to a measurement of humidity. Modern electronic devices use the temperature of condensation, or they sense changes in electrical capacitance or resistance to measure humidity differences. A crude hygrometer was invented by Leonardo da Vinci in 1480. Major leaps came forward during the 1600s; Francesco Folli invented a more practical version of the device, while Robert Hooke improved a number of meteorological devices including the hygrometer. A more modern version was created by Swiss polymath Johann Heinrich Lambert in 1755. Later, in the year 1783, Swiss physicist and Geologist Horace Bénédict de Saussure invented the first hygrometer using human hair to measure humidity.

Infrared thermography (IRT), thermal video and/or thermal imaging, is a process where a thermal camera captures and creates an image of an object by using infrared radiation emitted from the object in a process, which are examples of infrared imaging science. Thermographic cameras usually detect radiation in the long-infrared range of the electromagnetic spectrum and produce images of that radiation, called thermograms. Since infrared radiation is emitted by all objects with a temperature above absolute zero according to the black body radiation law, thermography makes it possible to see one's environment with or without visible illumination. The amount of radiation emitted by an object increases with temperature; therefore, thermography allows one to see variations in temperature. When viewed through a thermal imaging camera, warm objects stand out well against cooler backgrounds; humans and other warm-blooded animals become easily visible against the environment, day or night. As a result, thermography is particularly useful to the military and other users of surveillance cameras.

A radiant barrier is a type of building material that reflects thermal radiation and reduces heat transfer. Because thermal energy is also transferred by conduction and convection, in addition to radiation, radiant barriers are often supplemented with thermal insulation that slows down heat transfer by conduction or convection.

The emissivity of the surface of a material is its effectiveness in emitting energy as thermal radiation. Thermal radiation is electromagnetic radiation that most commonly includes both visible radiation (light) and infrared radiation, which is not visible to human eyes. A portion of the thermal radiation from very hot objects is easily visible to the eye.

The concept of mean radiant temperature (MRT) is used to quantify the exchange of radiant heat between a human and their surrounding environment, with a view to understanding the influence of surface temperatures on personal comfort. Mean radiant temperature has been both qualitatively defined and quantitatively evaluated for both indoor and outdoor environments.

An infrared thermometer is a thermometer which infers temperature from a portion of the thermal radiation sometimes called black-body radiation emitted by the object being measured. They are sometimes called laser thermometers as a laser is used to help aim the thermometer, or non-contact thermometers or temperature guns, to describe the device's ability to measure temperature from a distance. By knowing the amount of infrared energy emitted by the object and its emissivity, the object's temperature can often be determined within a certain range of its actual temperature. Infrared thermometers are a subset of devices known as "thermal radiation thermometers".

Underfloor heating and cooling is a form of central heating and cooling that achieves indoor climate control for thermal comfort using hydronic or electrical heating elements embedded in a floor. Heating is achieved by conduction, radiation and convection. Use of underfloor heating dates back to the Neoglacial and Neolithic periods.

Building insulation is material used in a building to reduce the flow of thermal energy. While the majority of insulation in buildings is for thermal purposes, the term also applies to acoustic insulation, fire insulation, and impact insulation. Often an insulation material will be chosen for its ability to perform several of these functions at once.

Thermal comfort is the condition of mind that expresses satisfaction with the thermal environment and is assessed by subjective evaluation. The human body can be viewed as a heat engine where food is the input energy. The human body will release excess heat into the environment, so the body can continue to operate. The heat transfer is proportional to temperature difference. In cold environments, the body loses more heat to the environment and in hot environments the body does not release enough heat. Both the hot and cold scenarios lead to discomfort. Maintaining this standard of thermal comfort for occupants of buildings or other enclosures is one of the important goals of HVAC design engineers.

Multi-layer insulation (MLI) is thermal insulation composed of multiple layers of thin sheets and is often used on spacecraft and cryogenics. Also referred to as superinsulation, MLI is one of the main items of the spacecraft thermal design, primarily intended to reduce heat loss by thermal radiation. In its basic form, it does not appreciably insulate against other thermal losses such as heat conduction or convection. It is therefore commonly used on satellites and other applications in vacuum where conduction and convection are much less significant and radiation dominates. MLI gives many satellites and other space probes the appearance of being covered with gold foil which is the effect of the amber-coloured Kapton layer deposited over the silver Aluminized mylar.

The Pirani gauge is a robust thermal conductivity gauge used for the measurement of the pressures in vacuum systems. It was invented in 1906 by Marcello Pirani.

A heat flux sensor is a transducer that generates an electrical signal proportional to the total heat rate applied to the surface of the sensor. The measured heat rate is divided by the surface area of the sensor to determine the heat flux.

Clothing insulation is the thermal insulation provided by clothing.

Radiant heating and cooling is a category of HVAC technologies that exchange heat by both convection and radiation with the environments they are designed to heat or cool. There are many subcategories of radiant heating and cooling, including: "radiant ceiling panels", "embedded surface systems", "thermally active building systems", and infrared heaters. According to some definitions, a technology is only included in this category if radiation comprises more than 50% of its heat exchange with the environment; therefore technologies such as radiators and chilled beams are usually not considered radiant heating or cooling. Within this category, it is practical to distinguish between high temperature radiant heating, and radiant heating or cooling with more moderate source temperatures. This article mainly addresses radiant heating and cooling with moderate source temperatures, used to heat or cool indoor environments. Moderate temperature radiant heating and cooling is usually composed of relatively large surfaces that are internally heated or cooled using hydronic or electrical sources. For high temperature indoor or outdoor radiant heating, see: Infrared heater. For snow melt applications see: Snowmelt system.

ANSI/ASHRAE Standard 55: Thermal Environmental Conditions for Human Occupancy is an American National Standard published by ASHRAE that establishes the ranges of indoor environmental conditions to achieve acceptable thermal comfort for occupants of buildings. It was first published in 1966, and since 2004 has been updated every three to six years. The most recent version of the standard was published in 2020.

Clothing physiology is a branch of science that studies the interaction between clothing and the human body, with a particular focus on how clothing affects the physiological and psychological responses of individuals to different environmental conditions. The goal of clothing physiology research is to develop a better understanding of how clothing can be designed to optimize comfort, performance, and protection for individuals in various settings, including outdoor recreation, occupational environments, and medical contexts.