A miner is a person who extracts ore, coal, chalk, clay, or other minerals from the earth through mining. There are two senses in which the term is used. In its narrowest sense, a miner is someone who works at the rock face; cutting, blasting, or otherwise working and removing the rock. In a broader sense, a "miner" is anyone working within a mine, not just a worker at the rock face.

A railroad car, railcar, railway wagon, railway carriage, railway truck, railwagon, railcarriage or railtruck, also called a train car, train wagon, train carriage or train truck, is a vehicle used for the carrying of cargo or passengers on a rail transport network. Such cars, when coupled together and hauled by one or more locomotives, form a train. Alternatively, some passenger cars are self-propelled in which case they may be either single railcars or make up multiple units.

A hopper car (US) or hopper wagon (UIC) is a type of railroad freight car that has opening doors on the underside or on the sides to discharge its cargo. They are used to transport loose solid bulk commodities such as coal, ore, grain, and track ballast. The hopper car was developed in parallel with the development of automated handling of such commodities, with automated loading and unloading facilities.

Bulk material handling is an engineering field that is centered on the design of equipment used for the handling of dry materials. Bulk materials are those dry materials which are powdery, granular or lumpy in nature, and are stored in heaps. Examples of bulk materials are minerals, ores, coal, cereals, woodchips, sand, gravel, clay, cement, ash, salt, chemicals, grain, sugar, flour and stone in loose bulk form. It can also relate to the handling of mixed wastes. Bulk material handling is an essential part of all industries that process bulk ingredients, including: food, beverage, confectionery, pet food, animal feed, tobacco, chemical, agricultural, polymer, plastic, rubber, ceramic, electronics, metals, minerals, paint, paper, textiles and more.

A rotary car dumper or wagon tippler (UK) is a mechanism used for unloading certain railroad cars such as hopper cars, gondolas or mine cars. It holds the rail car to a section of track and then rotates the track and car together to dump out the contents. Used with gondola cars, it is making open hopper cars obsolete. Because hopper cars require sloped chutes in order to direct the contents to the bottom dump doors (hatches) for unloading, gondola cars allow cars to be lower, thus lowering their center of gravity, while carrying the same gross rail load. Cars are equipped with rotary couplers to allow dumping them while they are still coupled; a "Double Rotary" gondola or hopper has rotary couplers on both ends to allow it to be unloaded while it remains coupled to stationary cars at each end.

The Bone Valley is a region of central Florida, encompassing portions of present-day Hardee, Hillsborough, Manatee, and Polk counties, in which phosphate is mined for use in the production of agricultural fertilizer. Florida currently contains the largest known deposits of phosphate in the United States.

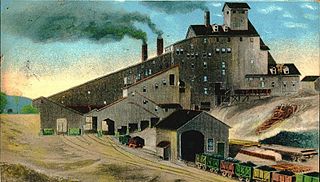

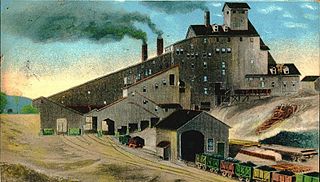

A coal breaker is a coal processing plant which breaks coal into various useful sizes. Coal breakers also remove impurities from the coal and deposit them into a culm dump. The coal breaker is a forerunner of the modern coal preparation plant.

A coal preparation plant is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more often than not, also loads coal into rail cars, barges, or ships.

The Cumberland Mine Railroad is a private carrier mine railroad serving the Cumberland Coal Resources mine near Waynesburg, Pennsylvania.

A minecart, mine cart, or mine car is a type of rolling stock found on a mine railway, used for transporting ore and materials procured in the process of traditional mining. Minecarts are seldom used in modern operations, having largely been superseded in underground operations by more efficient belt conveyor systems that allow machines such as longwall shearers and continuous miners to operate at their full capacity, and above ground by large dumpers.

The Duluth Works was an industrial steel and cement manufacturing complex located in Duluth, Minnesota, United States, in operation 1915 to 1987. The complex was operated by the United States Steel Corporation. Officially, the plant's purpose was to supply the growing Midwest with steel finished products. Unofficially, they were built as part of a "gentleman's agreement" between U.S. Steel and the State of Minnesota to not impose hefty iron ore taxes on U.S. Steel in exchange for a fully integrated steel plant within Minnesota, whose mines furnished 80% of the ore to U.S. Steel. The combined works of the steel and cement plant were the largest employers in Duluth and the fourth largest industrial complex in Minnesota.

Heyl & Patterson Equipment is an American specialist engineering company, founded in 1887 and based in Pittsburgh, Pennsylvania.

An open wagon forms a large group of railway goods wagons designed primarily for the transportation of bulk goods that are not moisture-retentive and can usually be tipped, dumped or shovelled. The International Union of Railways (UIC) distinguishes between ordinary wagons and special wagons (F/6). Open wagons often form a significant part of a railway company's goods wagon fleet; for example, forming just under 40% of the Deutsche Bahn's total goods wagon stock in Germany.

The South Waratah Colliery was a coal mine located at Charlestown, in New South Wales Australia.

The Reliance Tipple is the site of two coal tipples associated with coal production at Reliance, Wyoming. The first tipple was built in 1910 and used until 1936. The wood structure was built on a sandstone foundation and served Reliance Mines No. 1 through No. 6. The perishable portions of the earlier tipple have disappeared, leaving only the sandstone foundations and some artifacts buried in the tailings pile.

Duryea Yard is a railroad yard in the Wyoming Valley region of Northeastern Pennsylvania currently operated by the Reading Blue Mountain and Northern Railroad. Originally constructed in 1870 by Lehigh Valley Railroad as a turn-around and staging hub for coal transport from the Coal Region to Eastern big-city markets, the yard remains a hub for the energy extraction industry today.

Joy Global Inc. was a company that manufactured and serviced heavy equipment used in the extraction and haulage of coal and minerals in both underground and surface mining. The company had manufacturing facilities in Alabama, Pennsylvania, Texas, Wisconsin, Australia, Canada, China, France, South Africa, Poland and the United Kingdom. In 2017, Joy Global was acquired by Komatsu Limited and was renamed Komatsu Mining Corp.

A coaling tower, coal stage, coaling plant or coaling station is a facility used to load coal as fuel into railway steam locomotives. Coaling towers were often sited at motive power depots or locomotive maintenance shops.

The Transylvanian Mining Railway was a local interest narrow-gauge railway which was the first mining railway in Transylvania. This railway was built to ease the transportation of the iron ore mined from the iron ore mines from Ghelari to the blast furnace in Govăjdia and the ironworks from Hunedoara. This railway was also known as the "Hunedoara-Ghelari Local Interest Railway", "CFI Hunedoara", "Mocănița Hunedoara", "Calea Ferată Minieră Ardeleană", "Erdélyi Bányavasút" in Hungarian. The line was 10 km (6.2 mi) long from Hunedoara to Govăjdia and another 6 km (3.7 mi) from Govăjdia to the Retișoara terminus. This line was used by mixed trains that carried both iron ore and passengers from Ghelari to Govăjdia and Hunedoara's ironworks. They also transported dolomite and limestone from the limestone quarries near Govăjdia to the ironworks.

Acland No. 2 Colliery is a heritage-listed former mine at 2 Francis Street, Acland, Toowoomba Region, Queensland, Australia. It was added to the Queensland Heritage Register on 29 June 2007.