A jet engine is a type of reaction engine, discharging a fast-moving jet of heated gas that generates thrust by jet propulsion. While this broad definition may include rocket, water jet, and hybrid propulsion, the term jet engine typically refers to an internal combustion air-breathing jet engine such as a turbojet, turbofan, ramjet, or pulse jet. In general, jet engines are internal combustion engines.

The Pelton wheel or Pelton Turbine is an impulse-type water turbine invented by American inventor Lester Allan Pelton in the 1870s. The Pelton wheel extracts energy from the impulse of moving water, as opposed to water's dead weight like the traditional overshot water wheel. Many earlier variations of impulse turbines existed, but they were less efficient than Pelton's design. Water leaving those wheels typically still had high speed, carrying away much of the dynamic energy brought to the wheels. Pelton's paddle geometry was designed so that when the rim ran at half the speed of the water jet, the water left the wheel with very little speed; thus his design extracted almost all of the water's impulse energy—which made for a very efficient turbine.

A steam turbine is a machine that extracts thermal energy from pressurized steam and uses it to do mechanical work on a rotating output shaft. Its modern manifestation was invented by Charles Parsons in 1884. Fabrication of a modern steam turbine involves advanced metalwork to form high-grade steel alloys into precision parts using technologies that first became available in the 20th century; continued advances in durability and efficiency of steam turbines remains central to the energy economics of the 21st century.

A turbine is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. The work produced can be used for generating electrical power when combined with a generator. A turbine is a turbomachine with at least one moving part called a rotor assembly, which is a shaft or drum with blades attached. Moving fluid acts on the blades so that they move and impart rotational energy to the rotor. Early turbine examples are windmills and waterwheels.

A water turbine is a rotary machine that converts kinetic energy and potential energy of water into mechanical work.

The turbofan or fanjet is a type of airbreathing jet engine that is widely used in aircraft propulsion. The word "turbofan" is a combination of the preceding generation engine technology of the turbojet, and a reference to the additional fan stage added. It consists of a gas turbine engine which achieves mechanical energy from combustion, and a ducted fan that uses the mechanical energy from the gas turbine to force air rearwards. Thus, whereas all the air taken in by a turbojet passes through the combustion chamber and turbines, in a turbofan some of that air bypasses these components. A turbofan thus can be thought of as a turbojet being used to drive a ducted fan, with both of these contributing to the thrust.

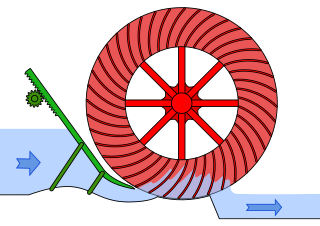

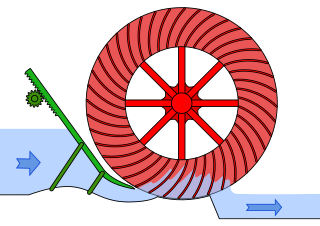

A cross-flow turbine, Bánki-Michell turbine, or Ossberger turbine is a water turbine developed by the Australian Anthony Michell, the Hungarian Donát Bánki and the German Fritz Ossberger. Michell obtained patents for his turbine design in 1903, and the manufacturing company Weymouth made it for many years. Ossberger's first patent was granted in 1933, and he manufactured this turbine as a standard product. Today, the company founded by Ossberger is the leading manufacturer of this type of turbine.

The turbojet is an airbreathing jet engine which is typically used in aircraft. It consists of a gas turbine with a propelling nozzle. The gas turbine has an air inlet which includes inlet guide vanes, a compressor, a combustion chamber, and a turbine. The compressed air from the compressor is heated by burning fuel in the combustion chamber and then allowed to expand through the turbine. The turbine exhaust is then expanded in the propelling nozzle where it is accelerated to high speed to provide thrust. Two engineers, Frank Whittle in the United Kingdom and Hans von Ohain in Germany, developed the concept independently into practical engines during the late 1930s.

The Francis turbine is a type of water turbine. It is an inward-flow reaction turbine that combines radial and axial flow concepts. Francis turbines are the most common water turbine in use today, and can achieve over 95% efficiency.

The Kaplan turbine is a propeller-type water turbine which has adjustable blades. It was developed in 1913 by Austrian professor Viktor Kaplan, who combined automatically adjusted propeller blades with automatically adjusted wicket gates to achieve efficiency over a wide range of flow and water level.

Lester Allan Pelton was an American inventor who contributed significantly to the development of hydroelectricity and hydropower in the American Old West as well as world-wide. In the late 1870s, he invented the Pelton water wheel, at that time the most efficient design of the impulse water turbine. Recognized as one of the fathers of hydroelectric power, he was awarded the Elliott Cresson Medal during his lifetime and is an inductee of the National Inventors Hall of Fame.

A propelling nozzle is a nozzle that converts the internal energy of a working gas into propulsive force; it is the nozzle, which forms a jet, that separates a gas turbine, or gas generator, from a jet engine.

Turbomachinery, in mechanical engineering, describes machines that transfer energy between a rotor and a fluid, including both turbines and compressors. While a turbine transfers energy from a fluid to a rotor, a compressor transfers energy from a rotor to a fluid.

Micro hydro is a type of hydroelectric power that typically produces from 5 kW to 100 kW of electricity using the natural flow of water. Installations below 5 kW are called pico hydro. These installations can provide power to an isolated home or small community, or are sometimes connected to electric power networks, particularly where net metering is offered. There are many of these installations around the world, particularly in developing nations as they can provide an economical source of energy without the purchase of fuel. Micro hydro systems complement solar PV power systems because in many areas water flow, and thus available hydro power, is highest in the winter when solar energy is at a minimum. Micro hydro is frequently accomplished with a pelton wheel for high head, low flow water supply. The installation is often just a small dammed pool, at the top of a waterfall, with several hundred feet of pipe leading to a small generator housing. In low head sites, generally water wheels and Archimedes' screws are used.

Specific speedNs, is used to characterize turbomachinery speed. Common commercial and industrial practices use dimensioned versions which are of equal utility. Specific speed is most commonly used in pump applications to define the suction specific speed —a quasi non-dimensional number that categorizes pump impellers as to their type and proportions. In Imperial units it is defined as the speed in revolutions per minute at which a geometrically similar impeller would operate if it were of such a size as to deliver one gallon per minute against one foot of hydraulic head. In metric units flow may be in l/s or m³/s and head in m, and care must be taken to state the units used.

Low-head hydropower refers to the development of hydroelectric power where the head is typically less than 20 metres, although precise definitions vary. Head is the vertical height measured between the hydro intake water level and the water level at the point of discharge. Using only a low head drop in a river or tidal flows to create electricity may provide a renewable energy source that will have a minimal impact on the environment. Since the generated power is a function of the head these systems are typically classed as small-scale hydropower, which have an installed capacity of less than 5MW.

The Poncelet wheel is a type of waterwheel invented by Jean-Victor Poncelet while working at the École d'Application in Metz. It roughly doubled the efficiency of existing undershot waterwheels through a series of detail improvements. The first Poncelet wheel was constructed in 1838, and the design quickly became common in France. Although the design was a great improvement on existing designs, further improvements in turbine design rendered the Poncelet wheel obsolete by the mid-century.

Francis turbine converts energy at high pressure heads which are not easily available and hence a turbine was required to convert the energy at low pressure heads, given that the quantity of water was large enough. It was easy to convert high pressure heads to power easily but difficult to do so for low pressure heads. Therefore, an evolution took place that converted the Francis turbine to Kaplan turbine, which generated power at even low pressure heads efficiently.

An axial turbine is a turbine in which the flow of the working fluid is parallel to the shaft, as opposed to radial turbines, where the fluid runs around a shaft, as in a watermill. An axial turbine has a similar construction as an axial compressor, but it operates in the reverse, converting flow of the fluid into rotating mechanical energy.

The water wall turbine is a water turbine designed to utilize hydrostatic pressure differences for low head hydropower generation. It supports bidirectional inflow operation using radial blades that rotate around a horizontal axis. The water wall turbine is suitable for energy extraction from tidal and freshwater currents. For tidal power installations, the turbine operates in both directions as the tide ebbs and flows.