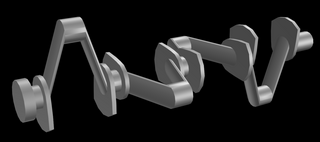

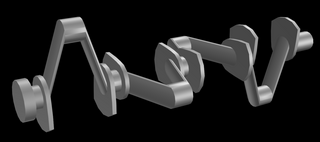

A crankshaft is a mechanical component used in a piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating shaft containing one or more crankpins, that are driven by the pistons via the connecting rods.

A V6 engine is a six-cylinder piston engine where the cylinders share a common crankshaft and are arranged in a V configuration.

A connecting rod, also called a 'con rod', is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the reciprocating motion of the piston into the rotation of the crankshaft. The connecting rod is required to transmit the compressive and tensile forces from the piston. In its most common form, in an internal combustion engine, it allows pivoting on the piston end and rotation on the shaft end.

A W12 engine is a twelve-cylinder piston engine where either three banks of four cylinders, or four banks of three cylinders are arranged in a W configuration around a common crankshaft.

The Ariès was a French automobile manufactured by La Société des Automobile Ariès in Asnières-sur-Seine. The firm was founded in 1902 by Baron Charles Petiet. The decision to end production was taken in 1937. Around 20,000 vehicles were produced in total.

The VR6 engine is a 6-cylinder engine configuration developed by VW. The name VR6 comes from the combination of German words “Verkürzt” and “Reihenmotor” meaning “shortened inline engine”. It was developed specifically for transverse engine installations and FWD vehicles. The VR6 is a highly compact engine, thanks to the narrower angle of 10.5 to 15-degrees between cylinder banks, as opposed to the traditional V6 angles ranging from 45 to 90-degrees. The compact design is cheaper to manufacture, since only one cylinder head is required for all 6 cylinders, much like a traditional inline-6 engine.

A W16 engine is a sixteen-cylinder piston engine with four banks of four cylinders in a W configuration.

The Ford flathead V8 is a V8 engine with a flat cylinder head designed by the Ford Motor Company and built by Ford and various licensees. During the engine's first decade of production, when overhead-valve engines were used by only a small minority of makes, it was usually known simply as the Ford V‑8, and the first car model in which it was installed, the Model 18, was often called simply the "Ford V-8", after its new engine. Although the V8 configuration was not new when the Ford V8 was introduced in 1932, the latter was a market first in the respect that it made an 8-cylinder affordable and a V engine affordable to the emerging mass market consumer for the first time. It was the first independently designed and built V8 engine produced by Ford for mass production, and it ranks as one of the company's most important developments. A fascination with ever-more-powerful engines was perhaps the most salient aspect of the American car and truck market for a half century, from 1923 until 1973. The engine was intended to be used for big passenger cars and trucks; it was installed in such until 1953, making the engine's 21-year production run for the U.S. consumer market longer than the 19-year run of the Ford Model T engine for that market. The engine was on Ward's list of the 10 best engines of the 20th century. It was a staple of hot rodders in the 1950s, and it remains famous in the classic car hobbies even today, despite the huge variety of other popular V8s that followed.

The Bugatti Type 32, commonly called the Tank de Tours, was a streamlined racing car built in 1923. It was built to compete in the French Grand Prix, which was held on July 2 in Tours on the same year.

Engine balance refers to how the inertial forces produced by moving parts in an internal combustion engine or steam engine are neutralised with counterweights and balance shafts, to prevent unpleasant and potentially damaging vibration. The strongest inertial forces occur at crankshaft speed and balance is mandatory, while forces at twice crankshaft speed can become significant in some cases.

The crossplane or cross-plane is a crankshaft design for piston engines with a 90° angle between the crank throws. The crossplane crankshaft is the most popular configuration used in V8 road cars.

A main bearing is a bearing in a piston engine which holds the crankshaft in place and allows it to rotate within the engine block.

A crankpin or crank pin, also known as a rod bearing journal, is a mechanical device in an engine which connects the crankshaft to the connecting rod for each cylinder. It has a cylindrical surface, to allow the crankpin to rotate relative to the "big end" of the connecting rod.

A big bang engine has an unconventional firing order designed so that some of the power strokes occur simultaneously or in close succession. This is achieved by changing the ignition timing, changing or re-timing the camshaft, and sometimes in combination with a change in crankpin angle. The goal is to change the power delivery characteristics of the engine. A regular firing multi-cylinder engine fires at approximately even intervals, giving a smooth-running engine. Because a big-bang engine has uneven power delivery, they tend to run rougher and generate more vibration than an even-firing engine.

The Rover 16/50 and Rover 16 are mid-sized cars which were produced by Rover from 1926 to 1929 and non-continuously from 1936 to 1947 respectively.

The Austin 15-20 is the smaller-engined of the almost identical pair of new cars announced by Herbert Austin in February 1906. A very complete catalogue with detailed specifications was issued at the same time. As well as the engine's smaller bore the 15-20 differed from the 25-30 by being only available with a live rear axle and not chain-drive. Otherwise the specifications were the same, the very minor differences are detailed below.

A tunnel crankcase, tunnel crankshaft or disc-webbed crankshaft is a design feature of a piston engine where the main bearings that support the crankshaft within the crankcase form the largest diameter of any part of the crankshaft and are larger than the crank webs. This requires a crankcase with a large tunnel instead of cross web supports for narrower main bearings, hence the name.

The Renault 100 hp, or 12B, aircraft engine from 1912 was a twelve-cylinder, air cooled 60° vee engine built by the French Renault company.

The De Dion-Bouton 130 hp aircraft engine, also referred to as De Dion-Bouton 12B, was a twelve-cylinder, air cooled vee aircraft engine that has been built by De Dion-Bouton.

The Renault 50/60 hp aircraft engines were a series of air cooled 90° V-8 engines with a bore and stroke of 90 mm × 120 mm built by the French Renault company in the years from 1908 to about 1911.