A lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis.

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the workpiece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or "freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material.

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry.

A machinist is a tradesperson or trained professional who operates machine tools, and has the ability to set up tools such as milling machines, grinders, lathes, and drilling machines.

In machining, numerical control, also called computer numerical control (CNC), is the automated control of tools by means of a computer. It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers. CNC transforms a piece of material into a specified shape by following coded programmed instructions and without a manual operator directly controlling the machining operation.

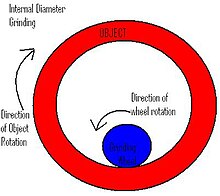

A grinding machine, often shortened to grinder, is a power tool used for grinding. It is a type of machining using an abrasive wheel as the cutting tool. Each grain of abrasive on the wheel's surface cuts a small chip from the workpiece via shear deformation.

The phrase speeds and feeds or feeds and speeds refers to two separate velocities in machine tool practice, cutting speed and feed rate. They are often considered as a pair because of their combined effect on the cutting process. Each, however, can also be considered and analyzed in its own right.

Grinding wheels are wheels that contain abrasive compounds for grinding and abrasive machining operations. Such wheels are also used in grinding machines.

A Tool and Cutter Grinder is used to sharpen milling cutters and tool bits along with a host of other cutting tools.

Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates.

Bryant is a brand of machine tools headquartered in Springfield, Vermont. Acquired by Fives in 2015, the Bryant product line specializes in the grinding field, building grinding machines with computer numerical control (CNC).

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. Centerless grinding differs from centered grinding operations in that no spindle or fixture is used to locate and secure the workpiece; the workpiece is secured between two rotary grinding wheels, and the speed of their rotation relative to each other determines the rate at which material is removed from the workpiece.

The Van Norman Machine Tool Company was an American machine tool builder from late in the 19th century until the mid-1980s. The company was based in Springfield, Massachusetts, USA. Its main areas of focus were milling machines and grinding machines. The company was acquired by Universal American Corporation during the early 1960s. Universal American later merged with Gulf and Western Industries.

Grinding is a type of abrasive machining process which uses a grinding wheel as cutting tool.

Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or grinding wheel against it along a controlled path. Honing is primarily used to improve the geometric form of a surface, but can also improve the surface finish.

Burnishing is the plastic deformation of a surface due to sliding contact with another object. It smooths the surface and makes it shinier. Burnishing may occur on any sliding surface if the contact stress locally exceeds the yield strength of the material. The phenomenon can occur both unintentionally as a failure mode, and intentionally as part of a metalworking or manufacturing process. It is a squeezing operation under cold working.

The rolling-elements of a rolling-element bearing ride on races. The large race that goes into a bore is called the outer race, and the small race that the shaft rides in is called the inner race.

In manufacturing, threading is the process of creating a screw thread. More screw threads are produced each year than any other machine element. There are many methods of generating threads, including subtractive methods ; deformative or transformative methods ; additive methods ; or combinations thereof.

Surface grinding is done on flat surfaces to produce a smooth finish.

Lewis Rasmus Heim was an American machinist and businessman who was the inventor of the Centerless Cylindrical Grinder, the Heim Joint Rod End Bearing and a pioneer of modern spherical, ball and roller bearings.