Related Research Articles

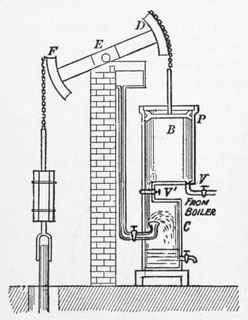

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from expanding gas in the cylinder to the crankshaft via a piston rod and/or connecting rod. In a pump, the function is reversed and force is transferred from the crankshaft to the piston for the purpose of compressing or ejecting the fluid in the cylinder. In some engines, the piston also acts as a valve by covering and uncovering ports in the cylinder.

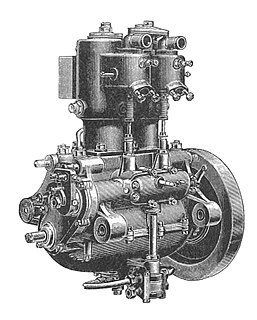

A reciprocating engine, also often known as a piston engine, is typically a heat engine that uses one or more reciprocating pistons to convert pressure into a rotating motion. This article describes the common features of all types. The main types are: the internal combustion engine, used extensively in motor vehicles; the steam engine, the mainstay of the Industrial Revolution; and the Stirling engine for niche applications. Internal combustion engines are further classified in two ways: either a spark-ignition (SI) engine, where the spark plug initiates the combustion; or a compression-ignition (CI) engine, where the air within the cylinder is compressed, thus heating it, so that the heated air ignites fuel that is injected then or earlier.

A two-strokeengine is a type of internal combustion engine that completes a power cycle with two strokes of the piston during one power cycle, this power cycle being completed in one revolution of the crankshaft. A four-stroke engine requires four strokes of the piston to complete a power cycle during two crankshaft revolutions. In a two-stroke engine, the end of the combustion stroke and the beginning of the compression stroke happen simultaneously, with the intake and exhaust functions occurring at the same time.

A petrol engine or gasoline engine is an internal combustion engine with spark-ignition, designed to run on petrol (gasoline) and similar volatile fuels.

The Napier Deltic engine is a British opposed-piston valveless, supercharged uniflow scavenged, two-stroke diesel engine used in marine and locomotive applications, designed and produced by D. Napier & Son. Unusually, the cylinders were disposed in a three-bank triangle, with a crankshaft at each corner of the triangle.

An opposed-piston engine is a piston engine in which each cylinder has a piston at both ends, and no cylinder head. Petrol and diesel opposed-piston engines have been used mostly in large-scale applications such as ships, military tanks, and factories.

William Hall Barnett, is described as a 'founder' in his 1836 patent, and an 'ironfounder' in his 1838 patent, and later as an engineer and gas engineer, working in Brighton, UK. He worked for many years for the Brighton and Hove General Gas Company.

A crankcase is the housing for the crankshaft in a reciprocating internal combustion engine. In most modern engines, the crankcase is integrated into the engine block.

The hot-bulb engine is a type of internal combustion engine in which fuel ignites by coming in contact with a red-hot metal surface inside a bulb, followed by the introduction of air (oxygen) compressed into the hot-bulb chamber by the rising piston. There is some ignition when the fuel is introduced, but it quickly uses up the available oxygen in the bulb. Vigorous ignition takes place only when sufficient oxygen is supplied to the hot-bulb chamber on the compression stroke of the engine.

A two-stroke diesel engine is an internal combustion engine that uses compression ignition, with a two-stroke combustion cycle. It was invented by Hugo Güldner in 1899.

A marine steam engine is a steam engine that is used to power a ship or boat. This article deals mainly with marine steam engines of the reciprocating type, which were in use from the inception of the steamboat in the early 19th century to their last years of large-scale manufacture during World War II. Reciprocating steam engines were progressively replaced in marine applications during the 20th century by steam turbines and marine diesel engines.

The Commer TS3 was a diesel engine fitted in Commer trucks built by the Rootes Group in the 1950s and 1960s. It was the first diesel engine used by the company.

Reciprocating engine cylinders are often classified by whether they are single- or double-acting, depending on how the working fluid acts on the piston.

A return connecting rod, return piston rod or double piston rod engine or back-acting engine is a particular layout for a steam engine.

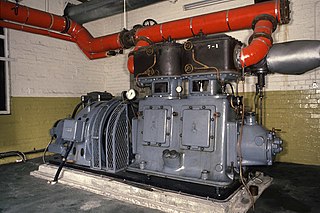

High-speed steam engines were one of the final developments of the stationary steam engine. They ran at a high speed, of several hundred rpm, which was needed by tasks such as electricity generation.

The Michel engine was an unusual form of opposed-piston engine. It was unique in that its cylinders, instead of being open-ended cylinders containing two pistons, were instead joined in a Y-shape and had three pistons working within them.

An internal combustion engine (ICE) is a heat engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is applied typically to pistons, turbine blades, a rotor, or a nozzle. This force moves the component over a distance, transforming chemical energy into useful work. This replaced the external combustion engine for applications where weight or size of the engine is important.

Stuart Turner Ltd is a British engineering company, based in Henley-on-Thames, Oxfordshire, England, founded by engineer Sidney Marmaduke Stuart Turner in 1906.

References

- 1 2 3 4 Irving, P E (1967). "Marine Engines". Vincent Marine Engine. Two Stroke Power Units. London: George Newnes. pp. 246–250.

- ↑ JK Siddorn. "Vincent marine engines". Archived from the original on 4 November 2012.

- 1 2 JK Siddorn (2 February 2010). "Vincent lifeboat engine and double acting pistons". Newsgroup: uk.rec.engines.stationary.

- ↑ Irving 1967 , p. 30

- ↑ Irving 1967 , pp. 35–37

- 1 2 3 4 5 6 JK Siddorn. "Vincent marine engines". Archived from the original on 4 November 2012.

- ↑ "Double marine engine genny1". JK Siddorn. Archived from the original on 4 November 2012.

- ↑ "Vincent Marine Engine". Stationary Engine Magazine (156). February 1987.

- ↑ "Vincent Amanda Water Scooter".

- ↑ "Vincent Amanda Jet Ski and Lawn Mower". 2 February 2011.