Related Research Articles

In physics, sputtering is a phenomenon in which microscopic particles of a solid material are ejected from its surface, after the material is itself bombarded by energetic particles of a plasma or gas. It occurs naturally in outer space, and can be an unwelcome source of wear in precision components. However, the fact that it can be made to act on extremely fine layers of material is utilised in science and industry—there, it is used to perform precise etching, carry out analytical techniques, and deposit thin film layers in the manufacture of optical coatings, semiconductor devices and nanotechnology products. It is a physical vapor deposition technique.

Isotope separation is the process of concentrating specific isotopes of a chemical element by removing other isotopes. The use of the nuclides produced is varied. The largest variety is used in research. By tonnage, separating natural uranium into enriched uranium and depleted uranium is the largest application. In the following text, mainly uranium enrichment is considered. This process is crucial in the manufacture of uranium fuel for nuclear power plants, and is also required for the creation of uranium-based nuclear weapons. Plutonium-based weapons use plutonium produced in a nuclear reactor, which must be operated in such a way as to produce plutonium already of suitable isotopic mix or grade.

Process engineering is the understanding and application of the fundamental principles and laws of nature that allow humans to transform raw material and energy into products that are useful to society, at an industrial level. By taking advantage of the driving forces of nature such as pressure, temperature and concentration gradients, as well as the law of conservation of mass, process engineers can develop methods to synthesize and purify large quantities of desired chemical products. Process engineering focuses on the design, operation, control, optimization and intensification of chemical, physical, and biological processes. Process engineering encompasses a vast range of industries, such as agriculture, automotive, biotechnical, chemical, food, material development, mining, nuclear, petrochemical, pharmaceutical, and software development. The application of systematic computer-based methods to process engineering is "process systems engineering".

An industrial process control or simply process control in continuous production processes is a discipline that uses industrial control systems and control theory to achieve a production level of consistency, economy and safety which could not be achieved purely by human manual control. It is implemented widely in industries such as automotive, mining, dredging, oil refining, pulp and paper manufacturing, chemical processing and power generating plants.

In the physical sciences, a partition coefficient (P) or distribution coefficient (D) is the ratio of concentrations of a compound in a mixture of two immiscible solvents at equilibrium. This ratio is therefore a comparison of the solubilities of the solute in these two liquids. The partition coefficient generally refers to the concentration ratio of un-ionized species of compound, whereas the distribution coefficient refers to the concentration ratio of all species of the compound.

Particle image velocimetry (PIV) is an optical method of flow visualization used in education and research. It is used to obtain instantaneous velocity measurements and related properties in fluids. The fluid is seeded with tracer particles which, for sufficiently small particles, are assumed to faithfully follow the flow dynamics. The fluid with entrained particles is illuminated so that particles are visible. The motion of the seeding particles is used to calculate speed and direction of the flow being studied.

A deaerator is a device that removes oxygen and other dissolved gases from liquids and pumpable compounds. Deaerators are considered water treatment equipment.

Pinch analysis is a methodology for minimising energy consumption of chemical processes by calculating thermodynamically feasible energy targets and achieving them by optimising heat recovery systems, energy supply methods and process operating conditions. It is also known as process integration, heat integration, energy integration or pinch technology.

In granulometry, the particle-size distribution (PSD) of a powder, or granular material, or particles dispersed in fluid, is a list of values or a mathematical function that defines the relative amount, typically by mass, of particles present according to size. Significant energy is usually required to disintegrate soil, etc. particles into the PSD that is then called a grain size distribution.

Cost-effective minimum water network is a holistic framework for water conservation which considers all conceivable methods to save water based on the water management hierarchy.

Water pinch analysis (WPA) originates from the concept of heat pinch analysis. WPA is a systematic technique for reducing water consumption and wastewater generation through integration of water-using activities or processes. WPA was first introduced by Wang and Smith. Since then, it has been widely used as a tool for water conservation in industrial process plants. Water Pinch Analysis has recently been applied for urban/domestic buildings. It was extended in 1998 by Nick Hallale at the University of Cape Town, who developed it as a special case of mass exchange networks for capital cost targeting.

A hydrologic model is a simplification of a real-world system that aids in understanding, predicting, and managing water resources. Both the flow and quality of water are commonly studied using hydrologic models.

Fault detection, isolation, and recovery (FDIR) is a subfield of control engineering which concerns itself with monitoring a system, identifying when a fault has occurred, and pinpointing the type of fault and its location. Two approaches can be distinguished: A direct pattern recognition of sensor readings that indicate a fault and an analysis of the discrepancy between the sensor readings and expected values, derived from some model. In the latter case, it is typical that a fault is said to be detected if the discrepancy or residual goes above a certain threshold. It is then the task of fault isolation to categorize the type of fault and its location in the machinery. Fault detection and isolation (FDI) techniques can be broadly classified into two categories. These include model-based FDI and signal processing based FDI.

Pharmaceutical manufacturing is the process of industrial-scale synthesis of pharmaceutical drugs as part of the pharmaceutical industry. The process of drug manufacturing can be broken down into a series of unit operations, such as milling, granulation, coating, tablet pressing, and others.

Hydrogen pinch analysis (HPA) is a hydrogen management method that originates from the concept of heat pinch analysis. HPA is a systematic technique for reducing hydrogen consumption and hydrogen generation through integration of hydrogen-using activities or processes in the petrochemical industry, petroleum refineries hydrogen distribution networks and hydrogen purification.

Water chemistry analyses are carried out to identify and quantify the chemical components and properties of water samples. The type and sensitivity of the analysis depends on the purpose of the analysis and the anticipated use of the water. Chemical water analysis is carried out on water used in industrial processes, on waste-water stream, on rivers and stream, on rainfall and on the sea. In all cases the results of the analysis provides information that can be used to make decisions or to provide re-assurance that conditions are as expected. The analytical parameters selected are chosen to be appropriate for the decision making process or to establish acceptable normality. Water chemistry analysis is often the groundwork of studies of water quality, pollution, hydrology and geothermal waters. Analytical methods routinely used can detect and measure all the natural elements and their inorganic compounds and a very wide range of organic chemical species using methods such as gas chromatography and mass spectrometry. In water treatment plants producing drinking water and in some industrial processes using products with distinctive taste and odours, specialised organoleptic methods may be used to detect smells at very low concentrations.

A spray is a dynamic collection of drops dispersed in a gas. The process of forming a spray is known as atomization. A spray nozzle is the device used to generate a spray. The two main uses of sprays are to distribute material over a cross-section and to generate liquid surface area. There are thousands of applications in which sprays allow material to be used most efficiently. The spray characteristics required must be understood in order to select the most appropriate technology, optimal device and size.

Vibratory Fluidized Bed (VFB) is a type of fluidized bed where the mechanical vibration enhances the performance of fluidization process. Since the first discovery of vibratory fluidized bed, its vibration properties proves to be more efficient in dealing with fine particles which appears to be very difficult to achieve with normal fluidized bed. Even though numerous publications and its popularity in industrial applications, the knowledge about vibratory dynamics and properties are very limited. Future research and development are needed to further improve this technology to bring it to another level.

Robustness, the ability to withstand failures and perturbations, is a critical attribute of many complex systems including complex networks.

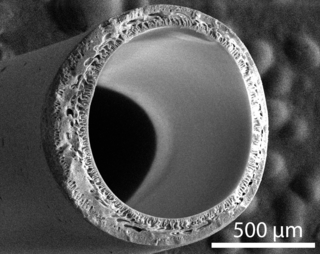

Hollow fiber membranes (HFMs) are a class of artificial membranes containing a semi-permeable barrier in the form of a hollow fiber. Originally developed in the 1960s for reverse osmosis applications, hollow fiber membranes have since become prevalent in water treatment, desalination, cell culture, medicine, and tissue engineering. Most commercial hollow fiber membranes are packed into cartridges which can be used for a variety of liquid and gaseous separations.

References

- ↑ Water cascade analysis technique for minimum flowrate targeting

- ↑ Manan, Z. A.; Tan, Y. L.; Foo, C. Y. (2004). "Targeting the Minimum Water Flowrate Using Water Cascade Analysis Technique". AIChE Journal. 50 (12): 3169–3183. doi:10.1002/aic.10235.

- ↑ Time dependent water cascade analysis

- ↑ Chwan Yee Foo, Dominic; Abdul Manan, Zainuddin (2006). "Setting the Minimum Utility Gas Flowrate Targets Using Cascade Analysis Technique". Industrial & Engineering Chemistry Research. 45 (17): 5986–5995. doi:10.1021/ie051322k.