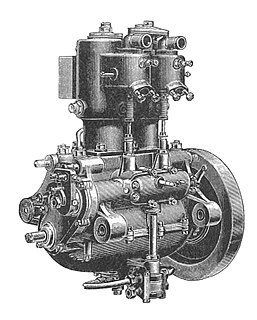

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from expanding gas in the cylinder to the crankshaft via a piston rod and/or connecting rod. In a pump, the function is reversed and force is transferred from the crankshaft to the piston for the purpose of compressing or ejecting the fluid in the cylinder. In some engines, the piston also acts as a valve by covering and uncovering ports in the cylinder.

An end-face mechanical seal, or a mechanical end-face seal, also referred to as a mechanical face seal but usually simply as a mechanical seal, is a type of seal utilised in rotating equipment, such as pumps, mixers, blowers, and compressors. When a pump operates, the liquid could leak out of the pump between the rotating shaft and the stationary pump casing. Since the shaft rotates, preventing this leakage can be difficult. Earlier pump models used mechanical packing to seal the shaft. Since World War II, mechanical seals have replaced packing in many applications.

A gasket is a mechanical seal which fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression.

A bottle cap seals the top opening of a bottle. A cap is typically colourfully decorated with the logo of the brand of beverage. Plastic caps are used for plastic bottles, while metal with plastic backing is used for glass; the metal is usually steel. Plastic caps may have a pour spout. Flip-Top caps like Flapper closures provide controlled dispensing of dry products. Caps for plastic bottles are often made of a different type of plastic from the bottle.

A gate valve, also known as a sluice valve, is a valve which opens by lifting gate out of the path of the fluid. Gate valves require very little space along the pipe axis and hardly restrict the flow of fluid when the gate is fully opened. The gate faces can be parallel, but are most commonly wedge-shaped.

Viton is a brand of FKM, a synthetic rubber and fluoropolymer elastomer commonly used in O-rings, chemical-resistant gloves, and other molded or extruded goods. The name is a registered trademark of The Chemours Company.

A mechanical seal is a device that helps join systems or mechanisms together by preventing leakage, containing pressure, or excluding contamination. The effectiveness of a seal is dependent on adhesion in the case of sealants and compression in the case of gaskets.

A Bridgman seal, invented by and named after Percy Williams Bridgman, can be used to seal a pressure chamber and compress its contents to high pressures, without the seal leaking and releasing the pressure

Hydraulic machines are machinery and tools that use liquid fluid power to do simple work, operated by the use of hydraulics, where a liquid is the powering medium. In heavy equipment and other types of machine, hydraulic fluid is transmitted throughout the machine to various hydraulic motors and hydraulic cylinders and becomes pressurised according to the resistance present. The fluid is controlled directly or automatically by control valves and distributed through hoses and tubes.

A beadlock or bead lock is a mechanical device that secures the bead of a tire to the wheel of a vehicle. Tires and wheels are designed so that, when the tire is inflated, the tire pressure pushes the bead of the tire against the inside of the wheel rim so that the tire stays on the wheel and the two rotate together. In situations where tire pressure is insufficient to hold the bead of the tire in place, a beadlock is needed.

A piston ring is a split ring that fits into a groove on the outer diameter of a piston in a reciprocating engine such as an internal combustion engine or steam engine.

A hydraulic seal is a relatively soft, non-metallic ring, captured in a groove or fixed in a combination of rings, forming a seal assembly, to block or separate fluid in reciprocating motion applications. Hydraulic seals are vital in machinery. Their use is critical in providing a way for fluid power to be converted to linear motion.

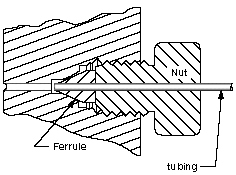

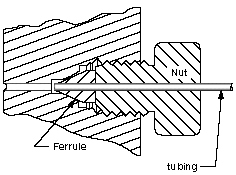

A fitting is used in pipe systems to connect the straight pipe or tubing sections, adapt to different sizes or shapes and for other purposes, such as regulating fluid flow. "Plumbing" is generally used to describe the conveyance of water, gas, or liquid waste in domestic or commercial environments; "piping" is often used to describe the high-performance conveyance of fluids in specialized applications. "Tubing" is sometimes used for lighter-weight piping, especially that flexible enough to be supplied in coiled form.

The oil pump in an internal combustion engine circulates engine oil under pressure to the rotating bearings, the sliding pistons and the camshaft of the engine. This lubricates the bearings, allows the use of higher-capacity fluid bearings and also assists in cooling the engine.

A junk head is a form of piston engine cylinder head, where the head is formed by a dummy piston mounted inside the top of the cylinder. In most other engine designs, the cylinder head is mounted on top of the cylinder block. That form has also been termed a "poultice head".

A monobloc or en bloc engine is an internal-combustion piston engine where some of the major components are formed, usually by casting, as a single integral unit, rather than being assembled later. This has the advantages of improving mechanical stiffness, and also improving the reliability of the sealing between them.

A dry-seal Wiggins gasholder is a device designed to hold gas.

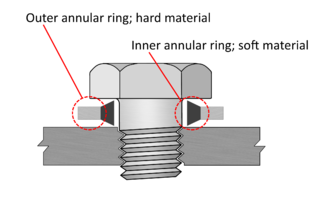

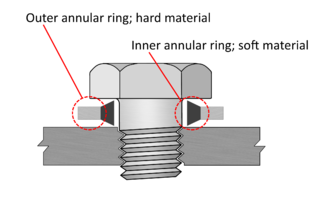

A bonded seal is a type of washer used to provide a seal around a screw or bolt. Originally made by Dowty Group, they are also known as Dowty seals or Dowty washers. Now widely manufactured, they are available in a range of standard sizes and materials