Bessemer is a city in Jefferson County, Alabama, United States and a southwestern suburb of Birmingham. The population was 26,019 at the 2020 census. It is within the Birmingham–Hoover, AL Metropolitan Statistical Area, of which Jefferson County is the center. It developed rapidly as an industrial city in the late 19th and early 20th centuries.

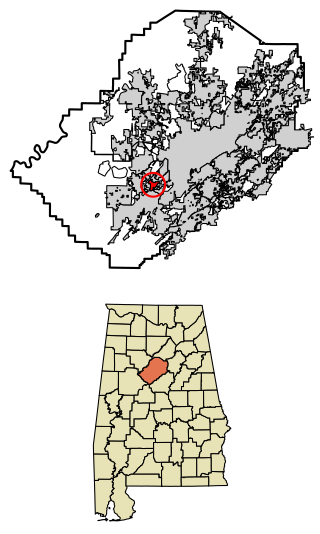

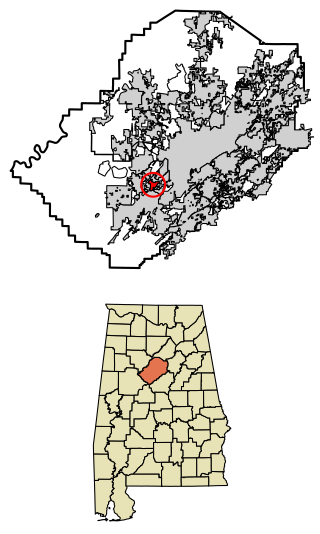

Brighton is a city near Birmingham, Alabama, United States and located just east of Hueytown. At the 2020 census, the population was 2,337. It is part of the Birmingham-Hoover Metropolitan Statistical Area, which in 2010 had a population of about 1,128,047, approximately one-quarter of Alabama's population.

Hueytown is a city in western Jefferson County, Alabama, United States. It is part of the Birmingham metropolitan area, and was part of the heavy industry development in this area in the 20th century. The population was 16,776 at the 2020 census.

Red Mountain is a long ridge running southwest-northeast and dividing Jones Valley from Shades Valley south of Birmingham, Alabama. It is part of the Ridge-and-Valley region of the Appalachian Mountains. The Red Mountain Formation of hard Silurian rock strata lies exposed in several long crests, and was named "Red Mountain" because of the rust-stained rock faces and prominent seams of red hematite iron ore. The mountain was the site of several mines that supplied iron ore to Birmingham's iron furnaces. Most of Birmingham's television and radio stations have transmission towers located on Red Mountain.

Sloss Furnaces is a National Historic Landmark in Birmingham, Alabama in the United States. It operated as a pig iron-producing blast furnace from 1882 to 1971. After closing, it became one of the first industrial sites in the U.S. to be preserved and restored for public use. In 1981, the furnaces were designated a National Historic Landmark by the United States Department of the Interior.

Republic Steel is an American steel manufacturer that was once the country's third largest steel producer. It was founded as the Republic Iron and Steel Company in Youngstown, Ohio in 1899. After rising to prominence during the early 20th Century, Republic suffered heavy economic losses and was eventually bought out before re-emerging in the early 2000s as a subsidiary. The company currently manufactures Special Bar Quality (SBQ) steel bars and employs around 2,000 people. It is currently owned by Grupo Simec, based in Guadalajara, Mexico.

An ironworks or iron works is an industrial plant where iron is smelted and where heavy iron and steel products are made. The term is both singular and plural, i.e. the singular of ironworks is ironworks.

The Birmingham District is a geological area in the vicinity of Birmingham, Alabama, where the raw materials for making steel - limestone, iron ore, and coal - are found together in abundance. The district includes Red Mountain, Jones Valley, and the Warrior and Cahaba coal fields in Central Alabama.

Ruffner Mountain Nature Preserve is a 1,038 acres (4.20 km2) nature preserve located in the eastern portion of Jefferson County, Alabama, in the City of Birmingham's historic South East Lake neighborhood. The preserve includes a visitor center containing native Alabama animals including raptors, snakes, turtles, and owls. The Ruffner Mountain area was home to iron ore mines and stone quarries, supplying the area's steel mills.

The Tannehill Ironworks is the central feature of Tannehill Ironworks Historical State Park near the unincorporated town of McCalla in Tuscaloosa County, Alabama. Listed on the National Register of Historic Places as Tannehill Furnace, it was a major supplier of iron for Confederate ordnance. Remains of the old furnaces are located 12 miles (19 km) south of Bessemer off Interstate 59/Interstate 20 near the southern end of the Appalachian Mountains. The 1,500-acre (610 ha) park includes: the John Wesley Hall Grist Mill; the May Plantation Cotton Gin House; and the Iron & Steel Museum of Alabama.

The Iron & Steel Museum of Alabama, also known as the Tannehill Museum, is an industrial museum that demonstrates iron production in the nineteenth-century Alabama located at Tannehill Ironworks Historical State Park in McCalla, Tuscaloosa County, Alabama. Opened in 1981, it covers 13,000 square feet (1,200 m2).

The Tennessee Coal, Iron and Railroad Company (1852–1952), also known as TCI and the Tennessee Company, was a major American steel manufacturer with interests in coal and iron ore mining and railroad operations. Originally based entirely within Tennessee, it relocated most of its business to Alabama in the late nineteenth century, following protests over its use of free convict labor. With a sizable real estate portfolio, the company owned several Birmingham satellite towns, including Ensley, Fairfield, Docena, Edgewater and Bayview. It also established a coal mining camp it sold to U.S. Steel which developed it into the Westfield, Alabama planned community.

The Wenonah community was the name of one of a series of Red Mountain ore mining camps for employees of the Tennessee Coal and Iron Company (TCI).

The Pyne Mine was a vertical shaft iron ore mine operated by the Woodward Iron Company and located near the Lacey's Chapel community outside Bessemer, Alabama, in Shades Valley. It was, along with Woodward's Songo Mine, one of only two shaft mines dug in the Birmingham District, and the last ore mine to operate in the region, closing in 1971.

The Sloss Mines are a group of mines in southwestern Jefferson County, Alabama, United States. They were established by the Sloss Iron and Steel Company and its successor, the Sloss-Sheffield Iron and Steel Company, on the southern end of Red Mountain. The Sloss Iron and Steel Company itself was founded by James Sloss in 1881 as the Sloss Furnace Company. The Sloss Mines produced iron ore from 1882 until the 1960s. The ore that these mines produced were essential to the production of iron at the Sloss Furnaces, making them an important element in the formation of adjacent Birmingham and Bessemer as cities.

The Mariscal Mine, also known as the Lindsey Mine and the Ellis Mine, was a source of cinnabar ore that was refined at the Texas site into mercury. The mine is located in what is now Big Bend National Park. The mine produced a total of 1400 flasks of mercury, each weighing 76 pounds (34 kg), accounting for almost a quarter of the mercury production in the United States between 1900 and 1943.

Docena is an unincorporated community in Jefferson County, Alabama, United States. Docena is 8 miles (13 km) west-northwest of downtown Birmingham and has a post office with ZIP code 35060.

The Shelby Iron Company was an iron manufacturing company that operated an ironworks in Shelby, Alabama. The iron company produced iron for the Confederate States of America and was destroyed towards the end of the American Civil War. The company continued to produce iron until the early part of the 20th century.

Allan Harvey "Rick" Woodward was an American businessman and baseball team owner.

Iron mining in the United States produced 48 million metric tons of iron ore in 2019. Iron ore was the third-highest-value metal mined in the United States, after gold and copper. Iron ore was mined from nine active mines and three reclamation operations in Michigan, Minnesota, and Utah. Most of the iron ore was mined in northern Minnesota's Mesabi Range. Net exports were 3.9 million tons. US iron ore made up 2.5 percent of the total mined worldwide in 2015. Employment as of 2014 was 5,750 in iron mines and iron ore treatment plants.