Teck Resources Limited, known as Teck Cominco until late 2008, is a diversified natural resources company headquartered in Vancouver, British Columbia, that is engaged in mining and mineral development, including coal for the steelmaking industry, copper, zinc, and energy. Secondary products include lead, silver, gold, molybdenum, germanium, indium and cadmium. Teck Resources was formed from the amalgamation of Teck and Cominco in 2001.

Boliden AB is a Swedish multinational metals, mining, and smelting company headquartered in Stockholm. The company produces zinc, copper, lead, nickel, silver, and gold, with operations in Sweden, Finland, Norway, and Ireland.

U.S. Silver & Gold Inc. was a mining company based in Wallace, Idaho near Coeur d'Alene, Idaho. The chairman of the company was Bobby E. Cooper, the CEO was Tom Parker.

The Silver Valley is a region in the northwest United States, in the Coeur d'Alene Mountains in northern Idaho. It is noted for its mining heritage, dating back to the 1880s.

Burke Canyon is the canyon of the Burke-Canyon Creek, which runs through the northernmost part of Shoshone County, Idaho, U.S., within the northeastern Silver Valley. A hotbed for mining in the late-nineteenth and twentieth centuries, Burke Canyon now contains several ghost towns and remnants of former communities along Idaho State Highway 4, which runs northeast through the narrow canyon to the Montana border.

Mount Isa Mines Limited ("MIM") operates the Mount Isa copper, lead, zinc and silver mines near Mount Isa, Queensland, Australia as part of the Glencore group of companies. For a brief period in 1980, MIM was Australia's largest company. It has pioneered several significant mining industry innovations, including the Isa Process copper refining technology, the Isasmelt smelting technology, and the IsaMill fine grinding technology, and it also commercialized the Jameson Cell column flotation technology.

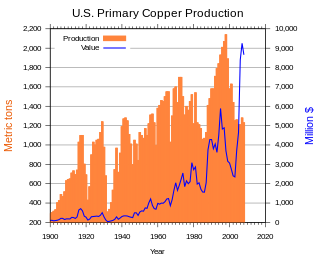

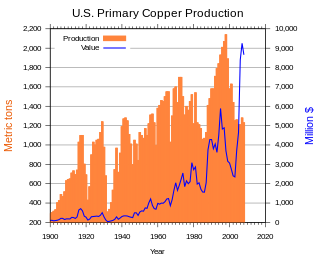

In the United States, copper mining has been a major industry since the rise of the northern Michigan copper district in the 1840s. In 2017, the US produced 1.27 million metric tonnes of copper, worth $8 billion, making it the world's fourth largest copper producer, after Chile, China, and Peru. Copper was produced from 23 mines in the US. Top copper producing states in 2014 were Arizona, Utah, New Mexico, Nevada, and Montana. Minor production also came from Idaho, and Missouri. As of 2014, the US had 45 million tonnes of known remaining reserves of copper, the fifth largest known copper reserves in the world, after Chile, Australia, Peru, and Mexico.

In the United States, gold mining has taken place continually since the discovery of gold at the Reed farm in North Carolina in 1799. The first documented occurrence of gold was in Virginia in 1782. Some minor gold production took place in North Carolina as early as 1793, but created no excitement. The discovery on the Reed farm in 1799 which was identified as gold in 1802 and subsequently mined marked the first commercial production.

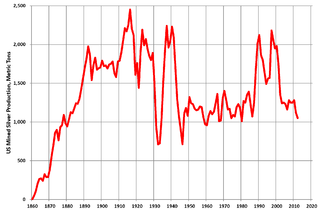

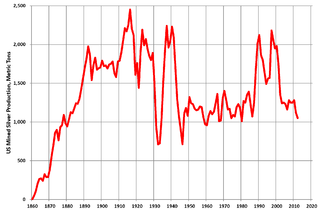

Silver mining in the United States began on a major scale with the discovery of the Comstock Lode in Nevada in 1858. The industry suffered greatly from the demonetization of silver in 1873 by the Coinage Act of 1873, known pejoratively as the "Crime of 73", but silver mining continues today.

Silver mining in Nevada, a state of the United States, began in 1858 with the discovery of the Comstock Lode, the first major silver-mining district in the United States. Nevada calls itself the "Silver State." Nevada is the nation's second-largest producer of silver, after Alaska. In 2014 Nevada produced 10.93 million troy ounces of silver, of which 6.74 million ounces were as a byproduct of the mining of gold. The largest byproducers were the Hycroft Mine, the Phoenix Mine, the Midas Mine and Round Mountain.

The Red Dog mine is a large zinc and lead mine in a remote region of Alaska, about 80 miles (130 km) north of Kotzebue, which is owned and operated by the Canadian mining company Teck Resources. It is located within the boundaries of the Red Dog Mine census-designated place in the Northwest Arctic Borough of the U.S. state of Alaska.

Gold mining in Alaska, a state of the United States, has been a major industry and impetus for exploration and settlement since a few years after the United States acquired the territory in 1867 from the Russian Empire. Russian explorers discovered placer gold in the Kenai River in 1848, but no gold was produced. Gold mining started in 1870 from placers southeast of Juneau, Alaska.

The Admiralty mining district is a mining area in the U.S. state of Alaska which consists of Admiralty Island. Silver and base metals are mined, with gold recovered as a by-product.

Coeur Mining, Inc. is a precious metals mining company listed on the New York Stock exchange. It operates five mines located in North America. Coeur employs 2,200 people and in 2012 it was the world's 9th largest silver producer. In 2013 the company changed its name to Coeur Mining, Inc. from Coeur d'Alene Mines and moved its head office to Chicago, Illinois from Coeur d'Alene, Idaho.

Tajikistan has rich deposits of gold, silver, and antimony. The largest silver deposits are in Sughd Province, where Tajikistan's largest gold mining operation is also located. Russia's Norilsk nickel company has explored a large new silver deposit at Bolshoy Kanimansur. More than 400 mineral deposits of some 70 different minerals have been discovered in Tajikistan, including strontium, tungsten, molybdenum, bismuth, salt, lead, zinc, fluorspar, and mercury. These minerals have been found suitable for mining. Uranium, an important mineral in the Soviet era, remains in some quantity but is no longer being extracted. The Tajikistan Aluminium Company (TALCO), an aluminium smelter, is the country's only large-scale production enterprise in the mining sector. Tajikistan hosts the annual Mining World Tajikistan, an international exhibition on mining in Dushanbe.

Hecla Mining is a gold, silver, and other precious metals mining company based in Coeur d'Alene, Idaho. Founded in 1891, it is the second-largest mining company that produces silver in the country. This area is known as the Silver Valley (Idaho). In 1983, this entire area was designated as a Superfund site by the Environmental Protection Agency, because of land, water, and air contamination resulting from a century of mostly unregulated silver and gold mining.

The Bunker Hill Mine and Smelting Complex was a large smelter located in Kellogg, Idaho, in the Coeur d'Alene Basin. When built, it was the largest smelting facility in the world. It is located in what became known as the Silver Valley of the Coeur d'Alene Basin, an area for a century that was a center of extensive silver and other metal mining and processing. This resulted in extensive contamination of water, land and air, endangering residents including the Coeur d'Alene Tribe, which had traditionally depended on fish from the waterways as part of its subsistence.

Zinc mining is the process by which mineral forms of the metal zinc are extracted from the earth through mining. A zinc mine is a mine that produces zinc minerals in ore as its primary product. Common co-products in zinc ores include minerals of lead and silver. Other mines may produce zinc minerals as a by-product of the production of ores containing more valuable minerals or metals, such as gold, silver or copper. Mined ore is processed, usually on site, to produce one or more metal-rich concentrates, then transported to a zinc smelter for production of zinc metal.

Mining in North Korea is important to the country's economy. North Korea is naturally abundant in metals such as magnesite, zinc, tungsten, and iron; with magnesite resources of 6 billion tonnes, particularly in the North and South Hamgyong Province and Chagang Province. However, often these cannot be mined due to the acute shortage of electricity in the country, as well as the lack of proper tools to mine these materials and an antiquated industrial base. Coal, iron ore, limestone, and magnesite deposits are larger than other mineral commodities. Mining joint ventures with other countries include China, Canada, Egypt, and South Korea.

Risdon Zinc Works is a major zinc refinery located in Lutana, a suburb of Hobart, Tasmania, Australia. The smelter is one of the world's largest in terms of production volume, producing over 280,000 tonnes annually of high-grade zinc, primarily as die-cast alloys and continuous galvanising-grade alloys. These products are exported for global markets and utilised in a wide range of industries and products, from building and infrastructure to transportation, business equipment, communications, electronics, and consumer goods. The facility produces zinc using the Roast, Leach, Electrowinning (RLE) method, creating leach byproducts, including cadmium, gypsum, copper sulphate, lead sulphate, sulphuric acid, paragoethite and leach concentrate. The refinery has been owned and operated by the global multi-metals business Nyrstar since 2007. Nyrstar Hobart works closely with the Nyrstar Port Pirie multi-metals smelter in South Australia. The facility is Tasmania's largest exporter, contributing 25% of the state's overall export value in 2013.