Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper and plastic substrates. Inkjet printers were the most commonly used type of printer in 2008, and range from small inexpensive consumer models to expensive professional machines. By 2019, laser printers outsold inkjet printers by nearly a 2:1 ratio, 9.6% vs 5.1% of all computer peripherals.

Selective laser sintering (SLS) is an additive manufacturing (AM) technique that uses a laser as the power and heat source to sinter powdered material, aiming the laser automatically at points in space defined by a 3D model, binding the material together to create a solid structure. It is similar to selective laser melting; the two are instantiations of the same concept but differ in technical details. SLS is a relatively new technology that so far has mainly been used for rapid prototyping and for low-volume production of component parts. Production roles are expanding as the commercialization of AM technology improves.

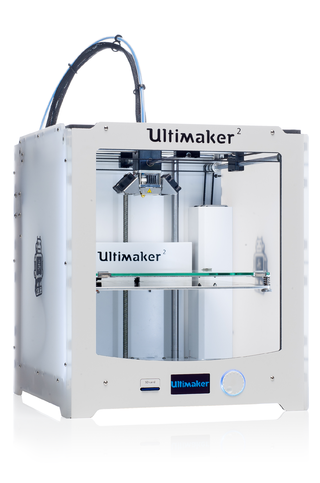

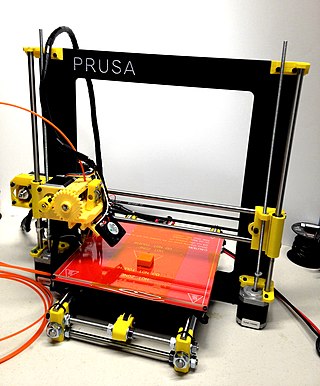

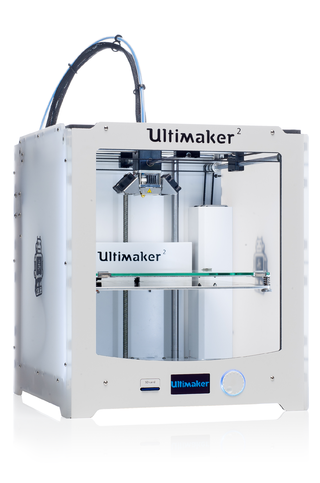

3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer control, with the material being added together, typically layer by layer.

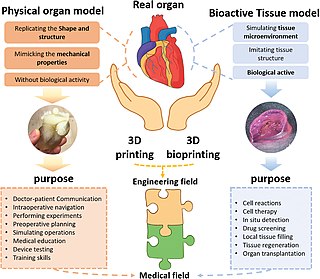

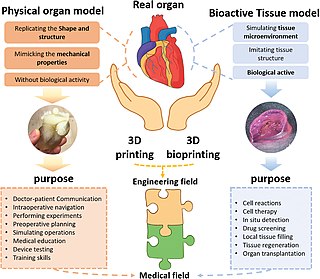

Organ printing utilizes techniques similar to conventional 3D printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3D object is produced. In the case of organ printing, the material being used by the printer is a biocompatible plastic. The biocompatible plastic forms a scaffold that acts as the skeleton for the organ that is being printed. As the plastic is being laid down, it is also seeded with human cells from the patient's organ that is being printed for. After printing, the organ is transferred to an incubation chamber to give the cells time to grow. After a sufficient amount of time, the organ is implanted into the patient.

Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer aided design (CAD) data. Construction of the part or assembly is usually done using 3D printing or "additive layer manufacturing" technology.

Digital modeling and fabrication is a design and production process that combines 3D modeling or computing-aided design (CAD) with additive and subtractive manufacturing. Additive manufacturing is also known as 3D printing, while subtractive manufacturing may also be referred to as machining, and many other technologies can be exploited to physically produce the designed objects.

Custom-fit means personalized with regard to shape and size. A customized product would imply the modification of some of its characteristics according to the customers requirements such as with a custom car. However, when fit is added to the term, customization could give the idea of both the geometric characteristics of the body and the individual customer requirements, e.g., the steering wheel of the Formula 1 driver Fernando Alonso.

Binder jet 3D printing, known variously as "Powder bed and inkjet" and "drop-on-powder" printing, is a rapid prototyping and additive manufacturing technology for making objects described by digital data such as a CAD file. Binder jetting is one of the seven categories of additive manufacturing processes according to ASTM and ISO.

Three dimensional (3D) bioprinting is the utilization of 3D printing–like techniques to combine cells, growth factors, bio-inks, and biomaterials to fabricate functional structures that were traditionally used for tissue engineering applications but in recent times have seen increased interest in other applications such as biosensing, and environmental remediation. Generally, 3D bioprinting utilizes a layer-by-layer method to deposit materials known as bio-inks to create tissue-like structures that are later used in various medical and tissue engineering fields. 3D bioprinting covers a broad range of bioprinting techniques and biomaterials. Currently, bioprinting can be used to print tissue and organ models to help research drugs and potential treatments. Nonetheless, translation of bioprinted living cellular constructs into clinical application is met with several issues due to the complexity and cell number necessary to create functional organs. However, innovations span from bioprinting of extracellular matrix to mixing cells with hydrogels deposited layer by layer to produce the desired tissue. In addition, 3D bioprinting has begun to incorporate the printing of scaffolds which can be used to regenerate joints and ligaments. Apart from these, 3D bioprinting has recently been used in environmental remediation applications, including the fabrication of functional biofilms that host functional microorganisms that can facilitate pollutant removal.

Solid Concepts, Inc. is a custom manufacturing company engaged in engineering, manufacturing, production, and prototyping. The company is headquartered in Valencia, California, in the Los Angeles County area, with six other facilities located around the United States. Solid Concepts is an additive manufacturing service provider as well as a major manufacturer of business products, aerospace, unmanned systems, medical equipment and devices, foundry cast patterns, industrial equipment and design, and transportation parts.

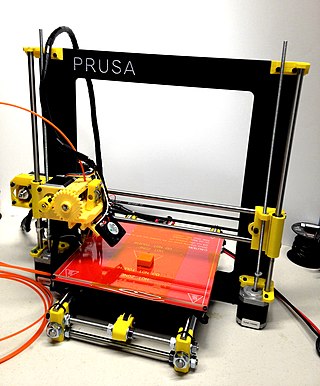

Fused filament fabrication (FFF), also known as fused deposition modeling, or filament freeform fabrication, is a 3D printing process that uses a continuous filament of a thermoplastic material. Filament is fed from a large spool through a moving, heated printer extruder head, and is deposited on the growing work. The print head is moved under computer control to define the printed shape. Usually the head moves in two dimensions to deposit one horizontal plane, or layer, at a time; the work or the print head is then moved vertically by a small amount to begin a new layer. The speed of the extruder head may also be controlled to stop and start deposition and form an interrupted plane without stringing or dribbling between sections. "Fused filament fabrication" was coined by the members of the RepRap project to give an acronym (FFF) that would be legally unconstrained in its use.

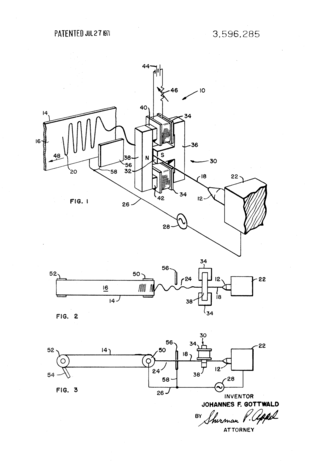

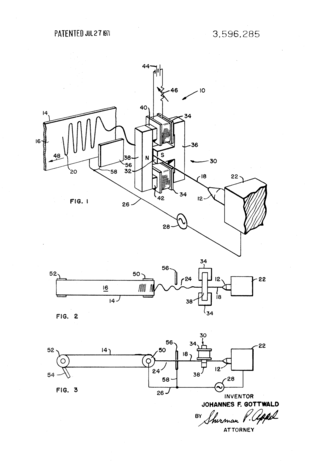

Inkjet technology originally was invented for depositing aqueous inks on paper in 'selective' positions based on the ink properties only. Inkjet nozzles and inks were designed together and the inkjet performance was based on a design. It was used as a data recorder in the early 1950s, later in the 1950s co-solvent-based inks in the publishing industry were seen for text and images, then solvent-based inks appeared in industrial marking on specialized surfaces and in the1990's phase change or hot-melt ink has become a popular with images and digital fabrication of electronic and mechanical devices, especially jewelry. Although the terms "jetting", "inkjet technology" and "inkjet printing", are commonly used interchangeably, inkjet printing usually refers to the publishing industry, used for printing graphical content, while industrial jetting usually refers to general purpose fabrication via material particle deposition.

Rule based DFM analysis for direct metal laser sintering. Direct metal laser sintering (DMLS) is one type of additive manufacturing process that allows layer by layer printing of metal parts having complex geometries directly from 3D CAD data. It uses a high-energy laser to sinter powdered metal under computer control, binding the material together to create a solid structure. DMLS is a net shape process and allows the creation of highly complex and customized parts with no extra cost incurred for its complexity.

3D metal moulding, also referred to as metal injection moulding or (MIM), is used to manufacture components with complex geometries. The process uses a mixture of metal powders and polymer binders – also known as "feedstock" – which are then injection-moulded.

In recent years, 3D printing has developed significantly and can now perform crucial roles in many applications, with the most common applications being manufacturing, medicine, architecture, custom art and design, and can vary from fully functional to purely aesthetic applications.

A variety of processes, equipment, and materials are used in the production of a three-dimensional object via additive manufacturing. 3D printing is also known as additive manufacturing, because the numerous available 3D printing process tend to be additive in nature, with a few key differences in the technologies and the materials used in this process.

Material extrusion-based additive manufacturing (EAM) represents one of the seven categories of 3d printing processes, defined by the ISO international standard 17296-2. While it is mostly used for plastics, under the name of FDM or FFF, it can also be used for metals and ceramics. In this AM process category, the feedstock materials are mixtures of a polymeric binder and a fine grain solid powder of metal or ceramic materials. Similar type of feedstock is also used in the Metal Injection Molding (MIM) and in the Ceramic Injection Molding (CIM) processes. The extruder pushes the material towards a heated nozzle thanks to

3D printing speed measures the amount of manufactured material over a given time period, where the unit of time is measured in Seconds, and the unit of manufactured material is typically measured in units of either kg, mm or cm3, depending on the type of additive manufacturing technique.

Multi-material 3D printing is the additive manufacturing procedure of using multiple materials at the same time to fabricate an object. Similar to single material additive manufacturing it can be realised through methods such as FFF, SLA and Inkjet 3D printing. By expanding the design space to different materials, it establishes the possibilities of creating 3D printed objects of different color or with different material properties like elasticity or solubility. The first multi-material 3D printer Fab@Home became publicly available in 2006. The concept was quickly adopted by the industry followed by many consumer ready multi-material 3D printers.

3D drug printing or 3D printing of pharmaceuticals is a technology that uses three-dimensional printing techniques to create customized pharmaceuticals, such as 3D printed tablets. It allows for precise control over the composition and dosage of drugs, enabling the production of personalized medicine tailored to an individual's specific needs, such as age, weight, and medical condition. This approach can be used to improve the effectiveness of drug therapies and to reduce side effects.