Broad sheet is a type of hand-blown glass. It was first made in Sussex in 1226. [1]

Broad sheet is a type of hand-blown glass. It was first made in Sussex in 1226. [1]

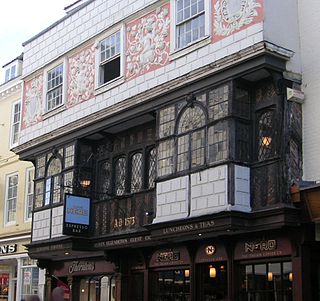

It is made by blowing molten glass into an elongated tube shape with a blowpipe. Then, while the glass is still hot, the ends are cut off and the resulting cylinder is split with shears and flattened on an iron plate. The quality of broad sheet glass is not good, with many imperfections and mostly translucent. Due to the relatively small sizes blown, broad sheet was typically made into leadlights. The centerpiece was used for decoration in places where looking through the glass wasn't vital. If the piece was large, it was possible to see bubble tracks and strain lines. [2]

Other methods for making hand-blown glass included blown plate glass, crown glass (introduced to England in the 17th century), polished plate glass and cylinder blown sheet glass. These methods of manufacture lasted at least until the end of the 19th century. The early 20th century marks the move away from hand-blown to machine manufactured glass such as rolled plate glass, machine drawn cylinder sheet glass, flat drawn sheet glass, single and twin ground polished plate glass and float glass.

Broad sheet glass was first made in the UK in [3] Chiddingfold, Surrey on the border with Sussex in 1226. In 1240 an order [4] was placed for this glass to be used in Westminster Abbey. This glass was of poor quality and fairly opaque. Manufacture slowly decreased and ceased by the early 16th century. The choice of this location [5] may have been due to the availability of sand, the abundance of bracken (the ash of which can be used to make potash for soda glass) and the significant beech forests to provide charcoal as fuel for the kiln. Examples of glass from this area can be found in Guildford Museum.

Whilst French glass-makers and others were making broad sheet glass earlier than this [1] notably William Le Verrier, Schurterrers and John Alemayne. [4] Between 1350 and 1356 Alemayne [4] secured orders for glass to be used in St. Stephens Chapel, Westminster and St Georges Chapel, Windsor.

Stained glass is coloured glass as a material or works created from it. Throughout its thousand-year history, the term has been applied almost exclusively to the windows of churches and other significant religious buildings. Although traditionally made in flat panels and used as windows, the creations of modern stained glass artists also include three-dimensional structures and sculpture. Modern vernacular usage has often extended the term "stained glass" to include domestic lead light and objets d'art created from foil glasswork exemplified in the famous lamps of Louis Comfort Tiffany.

Glassblowing is a glassforming technique that involves inflating molten glass into a bubble with the aid of a blowpipe. A person who blows glass is called a glassblower, glassmith, or gaffer. A lampworker manipulates glass with the use of a torch on a smaller scale, such as in producing precision laboratory glassware out of borosilicate glass.

Float glass is a sheet of glass made by floating molten glass on a bed of molten metal of a low melting point, typically tin, although lead was used for the process in the past. This method gives the sheet uniform thickness and a very flat surface.

Old Sheffield Plate is the name generally given to the material developed by Thomas Boulsover in the 1740s, a fusion of copper and silver which could be made into a range of items normally made in solid silver. The material rapidly gained popularity as a substitute for solid silver, as it was much cheaper to produce. Any object made in silver could in effect be made in Old Sheffield Plate, although objects subject to heavy wear such as spoons and forks were not so satisfactory in plate.

Chiddingfold is a village and civil parish in the Weald in the Waverley district of Surrey, England. It lies on the A283 road between Milford and Petworth. The parish includes the hamlets of Ansteadbrook, High Street Green and Combe Common.

Cathedral glass is the name given commercially to monochromatic sheet glass. It is thin by comparison with slab glass, may be coloured, and is textured on one side.

Glass tubes are mainly cylindrical hollow-wares. Their special shape combined with the huge variety of glass types, allows the use of glass tubing in many applications. For example, laboratory glassware, lighting applications, solar thermal systems and pharmaceutical packaging to name the largest.

Glass bead making has long traditions, with the oldest known beads dating over 3,000 years. Glass beads have been dated back to at least Roman times. Perhaps the earliest glass-like beads were Egyptian faience beads, a form of clay bead with a self-forming vitreous coating. Glass beads are significant in archaeology because the presence of glass beads often indicate that there was trade and that the bead making technology was being spread. In addition, the composition of the glass beads could be analyzed and help archaeologists understand the sources of the beads.

Blown plate is a hand-blown glass. There is a record of blown plate being produced in London in 1620.

Polished plate is a type of hand-made glass. It is produced by casting glass onto a table and then subsequently grinding and polishing the glass. This was originally done by hand, and then later by machine. It was an expensive process requiring a large capital investment.

Cylinder blown sheet is a type of hand-blown window glass. It is created with a similar process to broad sheet, but with the use of larger cylinders. In this manufacturing process glass is blown into a cylindrical iron mold. The ends are cut off and a cut is made down the side of the cylinder. The cut cylinder is then placed in an oven where the cylinder unrolls into a flat glass sheet. William J. Blenko used this method in the early 1900s to make stained glass. The result is much larger panes and improved surface quality over broad sheet, although still containing some imperfections. These imperfect panes have led to the misconception that glass is actually a high-viscosity fluid at room temperature, which is not the case.

Machine drawn cylinder sheet was the first mechanical method for "drawing" window glass. Cylinders of glass 40 feet (12 m) high are drawn vertically from a circular tank. The glass is then annealed and cut into 7 to 10 foot cylinders. These are cut lengthways, reheated, and flattened.

Crown glass was an early type of window glass. In this process, glass was blown into a "crown" or hollow globe. This was then transferred from the blowpipe to a punty and then flattened by reheating and spinning out the bowl-shaped piece of glass (bullion) into a flat disk by centrifugal force, up to 5 or 6 feet in diameter. The glass was then cut to the size required.

Architectural glass is glass that is used as a building material. It is most typically used as transparent glazing material in the building envelope, including windows in the external walls. Glass is also used for internal partitions and as an architectural feature. When used in buildings, glass is often of a safety type, which include reinforced, toughened and laminated glasses.

Clayton and Bell was one of the most prolific and proficient British workshops of stained-glass windows during the latter half of the 19th century and early 20th century. The partners were John Richard Clayton (1827–1913) and Alfred Bell (1832–1895). The company was founded in 1855 and continued until 1993. Their windows are found throughout the United Kingdom, in the United States, Canada, Australia and New Zealand.

Tiffany glass refers to the many and varied types of glass developed and produced from 1878 to 1933 at the Tiffany Studios in New York City, by Louis Comfort Tiffany and a team of other designers, including Clara Driscoll, Agnes F. Northrop, and Frederick Wilson.

Chance Brothers and Company was a glassworks originally based in Spon Lane, Smethwick, West Midlands, in England. It was a leading glass manufacturer and a pioneer of British glassmaking technology.

Plate glass, flat glass or sheet glass is a type of glass, initially produced in plane form, commonly used for windows, glass doors, transparent walls, and windscreens. For modern architectural and automotive applications, the flat glass is sometimes bent after production of the plane sheet. Flat glass stands in contrast to container glass and glass fibre.

The history of glass-making dates back to at least 3,600 years ago in Mesopotamia. However, some writers claim that they may have been producing copies of glass objects from Egypt. Other archaeological evidence suggests that the first true glass was made in coastal north Syria, Mesopotamia or Egypt. The earliest known glass objects, of the mid 2,000 BCE, were beads, perhaps initially created as the accidental by-products of metal-working (slags) or during the production of faience, a pre-glass vitreous material made by a process similar to glazing. Glass products remained a luxury until the disasters that overtook the late Bronze Age civilizations seemingly brought glass-making to a halt.

Glazing, which derives from the Middle English for 'glass', is a part of a wall or window, made of glass. Glazing also describes the work done by a professional "glazier". Glazing is also less commonly used to describe the insertion of ophthalmic lenses into an eyeglass frame.