A cotton mill is a building that houses spinning or weaving machinery for the production of yarn or cloth from cotton, an important product during the Industrial Revolution in the development of the factory system.

Dukinfield Junction is the name of the canal junction where the Peak Forest Canal, the Ashton Canal and the Huddersfield Narrow Canal meet near Ashton-under-Lyne, Greater Manchester, England. The area has been designated by Tameside Metropolitan Borough Council as a conservation area.

Ring spinning is a method of spinning fibres, such as cotton, flax or wool, to make a yarn. The ring frame developed from the throstle frame, which in its turn was a descendant of Arkwright's water frame. Ring spinning is a continuous process, unlike mule spinning which uses an intermittent action. In ring spinning, the roving is first attenuated by using drawing rollers, then spun and wound around a rotating spindle which in its turn is contained within an independently rotating ring flyer. Traditionally ring frames could only be used for the coarser counts, but they could be attended by semi-skilled labour.

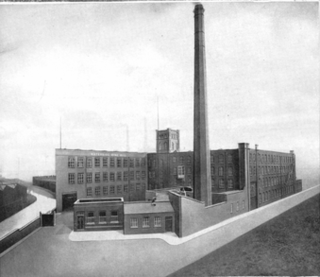

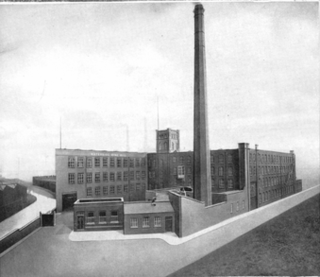

Tudor Mill was cotton spinning mill in Ashton-under-Lyne, in the historic county of Lancashire, England. It was built between 1901 and 1903 for the Ashton Syndicate by Sydney Stott of Oldham. Tudor Mill was next to the Ashton Canal Warehouse at Portland Basin. It ceased spinning cotton in the 1960s and was used as a warehouse until it was destroyed by fire in 1970

Minerva Mill was a cotton spinning mill in Ashton-under-Lyne, Greater Manchester, England. It was built between 1891 and 1892 for the Minerva Spinning Company which was later known as the Ashton Syndicate. Minerva Mill was next to the later Texas mill, at Whitelands. It ceased spinning cotton in the 1920s and was demolished in 1937.

Rock Mill was cotton spinning mill in the Waterloo district of Ashton-under-Lyne, Greater Manchester, in England. It was built between 1891 and 1893 for the Ashton Syndicate by Sydney Stott of Oldham. Rock Mill was built on the site of Wilshaw Mill retaining and using the octagonal chimney. It ceased spinning cotton in the 1960s and was demolished in 1971; the site became the location for the town's first Asda supermarket, which opened in 1972, until Asda relocated to a much larger new store site in Cavendish Street in 1989.

Atlas Mill was a cotton spinning mill in the Waterloo district of Ashton-under-Lyne, Greater Manchester, in England. It was built between 1898 and 1900 for the Ashton Syndicate by Sydney Stott of Oldham. It was last mill in Ashton to cease spinning. It was spinning artificial fibres in 1987, and was demolished in 1994; the site is now a housing estate.

Texas Mill was a cotton spinning mill in the Whitelands district of Ashton-under-Lyne, Greater Manchester, in England. It was built between 1905 and 1907 for the Ashton Syndicate by Sydney Stott of Oldham. It was destroyed in a massive fire on 22–23 October 1971. It had been re-equipped as a ring mill for spinning artificial fibres when it was destroyed.

Curzon Mill, later known as Alger Mill was a cotton spinning mill in the Hurst district of Ashton-under-Lyne, Greater Manchester, in England. It was built between 1899 and 1902 for the Ashton Syndicate by Sydney Stott of Oldham. It was a sister mill to the Atlas Mill. It was sold to the Alger Spinning Co. Ltd in 1911, and closed in 1942. It was then used as a cigarette factory by the J.A. Pattreiouex company until 1966, and then sold to the Qualitex company for the production of artificial fibres. It was still spinning artificial fibres in the 1990s and was demolished in 1994; the site being used for a housing estate.

Cedar Mill was a cotton spinning mill in the Hurst area of Ashton-under-Lyne, Greater Manchester, in England. It was built between 1903 and 1905 for the Ashton Syndicate by Sydney Stott of Oldham. It was the last mill in Ashton spinning cotton. It ceased in 1980. It was demolished and the land was used for housing.

The Junction Mills were cotton spinning and weaving mills to the west of the Portland Basin in Ashton-under-Lyne, Greater Manchester, in England. They were built between 1831 and 1890 for the Samuel Heginbottom and his sons. The firm went out of business in 1930, and all the buildings have been demolished but the 210 feet (64 m) octagonal chimney, built in 1867, and typical of that period has been preserved in situ.

Arkwright Mill, Rochdale is a cotton spinning mill in Rochdale, Greater Manchester. It was built in 1885 by the Arkwright Cotton Spinning Co. It was taken over by the Lancashire Cotton Corporation in the 1930s and passed to Courtaulds in 1964. It was located next to Dale Mill on Roch Street. The ring and doubling frames were made by Howard & Bullough, Accrington. The mill closed in 1980, was demolished in 2007 and the land redeveloped for housing.

Waterside Mill, Ashton-under-Lyne was a combined cotton spinning weaving mill in Whitelands, Ashton-under-Lyne, Greater Manchester, England. It was built as two independent factories. The weaving sheds date from 1857; the four-storey spinning mill dates from 1863. The spinning was taken over by the Lancashire Cotton Corporation in the 1930s. Production finished in 1959. Waterside Mill was converted to electricity around 1911.

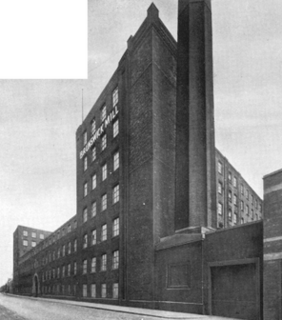

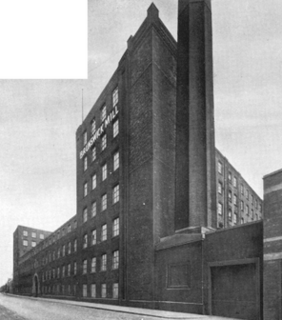

Brunswick Mill, Ancoats is a former cotton spinning mill on Bradford Road in Ancoats, Manchester, England. The mill was built around 1840, part of a group of mills built along the Ashton Canal, and at that time it was one of the country's largest mills. It was built round a quadrangle, a seven-storey block facing the canal. It was taken over by the Lancashire Cotton Corporation in the 1930s and passed to Courtaulds in 1964. Production finished in 1967.

Saxon Mill, Droylsden was a cotton spinning mill in Droylsden, Tameside, Greater Manchester, England. It was built in the 1907, taken over by the Lancashire Cotton Corporation in the 1930s and passed to Courtaulds in 1964. Production finished in 1967, and the mill was demolished in 1995.

Malta Mill, Middleton is a former cotton spinning mill in the Mills Hill area of Chadderton, Greater Manchester. It lies alongside the Rochdale Canal. It was built in 1904 as a new mule mill, by F. W. Dixon The engine stopped in 1963. The building still stands.

Kingston Mill, Stockport is a mid nineteenth century cotton spinning mill in Edgeley, Stockport, Greater Manchester, England. It was taken over by the Lancashire Cotton Corporation in the 1930s and passed to Courtaulds in 1964. Production finished, it was made over to multiple uses.

Ellenroad Mill was a cotton spinning mill in Newhey, Milnrow, Rochdale, Greater Manchester, England. It was built as a mule spinning mill in 1890 by Stott and Sons and extended in 1899. It was destroyed by fire on 19 January 1916. When it was rebuilt, it was designed and equipped as a ring spinning mill.

Tower Mill is a cotton mill in Dukinfield, Greater Manchester, England. It is a grade II listed building. It was designed by Potts, Pickup & Dixon in 1885 and spun cotton, using mules and spinning frames until 1955 when it was no longer used as a cotton mill and was subsequently used by various industries and divided into small units, at one point plans were even passed for the mill to be converted into luxury apartments but with the recession in 2007/8 this plan was abandoned. After several years of lying empty it was eventually bought in 2013, restored and re-equipped to ring spin superfine cotton yarns in 2016 and is now after the absence for many years the only cotton mill in production in the United Kingdom.