The Allison V-1710 aircraft engine designed and produced by the Allison Engine Company was the only US-developed V-12 liquid-cooled engine to see service during World War II. Versions with a turbocharger gave excellent performance at high altitude in the twin-engined Lockheed P-38 Lightning, and turbo-superchargers were fitted to experimental single-engined fighters with similar results.

The Jumo 205 aircraft engine was the most famous of a series of aircraft diesel engines produced by Junkers. The Jumo 204 first entered service in 1932. Later engines of this type comprised the experimental Jumo 206 and Jumo 208, with the Jumo 207 produced in some quantity for the Junkers Ju 86P and -R high-altitude reconnaissance aircraft, and the 46-meter wingspan, six-engined Blohm & Voss BV 222 Wiking flying boat. All three of these variants differed in stroke and bore and supercharging arrangements. In all, more than 900 of these engines were produced, in the 1930s and through most of World War II.

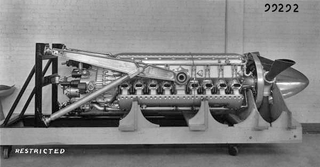

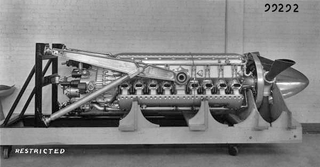

The hyper engine was a 1930s study project by the United States Army Air Corps (USAAC) to develop a high-performance aircraft engine that would be equal to or better than the aircraft and engines then under development in Europe. The project goal was to produce an engine that was capable of delivering 1 hp/in3 (46 kW/L) of engine displacement for a weight of less than 1 lb/hp delivered. The ultimate design goal was an increased power-to-weight ratio suitable for long-range airliners and bombers.

The Jumo 222 was a German high-power multiple-bank in-line piston aircraft engine from Junkers, designed under the management of Ferdinand Brandner of the Junkers Motorenwerke.

The Jumo 204 was an opposed-piston, inline, liquid-cooled 6-cylinder aircraft Diesel engine produced by the German manufacturer Junkers. It entered service in 1932. Later engines in the series, the Jumo 205, Jumo 206, Jumo 207 and Jumo 208, differed in stroke, bore, and supercharging arrangements.

The Jumo 211 was a German inverted V-12 aircraft engine, Junkers Motoren's primary aircraft engine of World War II. It was the direct competitor to the Daimler-Benz DB 601 and closely paralleled its development. While the Daimler-Benz engine was mostly used in single-engined and twin-engined fighters, the Jumo engine was primarily used in bombers such as Junkers' own Ju 87 and Ju 88, and Heinkel's H-series examples of the Heinkel He 111 medium bomber. It was the most-produced German aero engine of the war, with almost 70,000 examples completed.

The Daimler-Benz DB 601 was a German aircraft engine built during World War II. It was a liquid-cooled inverted V12, and powered the Messerschmitt Bf 109, Messerschmitt Bf 110, and many others. Approximately 19,000 601's were produced before it was replaced by the improved Daimler-Benz DB 605 in 1942.

The Junkers Jumo 213 was a World War II-era V-12 liquid-cooled aircraft engine, a development of Junkers Motoren's earlier design, the Jumo 211. The design added two features, a pressurized cooling system that required considerably less cooling fluid which allowed the engine to be built smaller and lighter, and a number of improvements that allowed it to run at higher RPM. These changes boosted power by over 500 hp and made the 213 one of the most sought-after Axis engine designs in the late-war era.

The Jumo 210 was Junkers Motoren's first production inverted V12 gasoline aircraft engine, first produced in the early 1930s. Depending on the version it produced between 610 and 730 PS and can be considered a counterpart of the Rolls-Royce Kestrel in many ways. Although originally intended to be used in almost all pre-war designs, rapid progress in aircraft design quickly relegated it to the small end of the power scale by the late 1930s. Almost all aircraft designs switched to the much larger Daimler-Benz DB 600, so the 210 was produced only for a short time before Junkers responded with a larger engine of their own, the Junkers Jumo 211.

The Chrysler XIV-2220 was an experimental 2,500 hp, 2,220 cubic inch liquid-cooled inverted-V-16 aircraft engine designed by Chrysler starting in 1940. Although several aircraft designs had considered using it, by the time it was ready for use in 1945 the war was already over. Only a few engines were built during the program, and it retained its 'X' designation the entire time as the XIV-2220, later XI-2220. The IV-2220 is historically important as it was Chrysler's first hemi, a design that would re-appear for many years later and is now a Chrysler trademark.

The Lycoming XR-7755 was the largest piston aircraft engine ever built in the United States, with 36 cylinders totaling about 7,750 in³ (127 L) of displacement and a power output of 5,000 horsepower (3,700 kilowatts). It was originally intended to be used in the "European bomber" that eventually emerged as the Convair B-36. Only two examples were built before the project was terminated in 1946.

The Daimler-Benz DB 605 is a German aircraft engine built during World War II. Developed from the DB 601, the DB 605 was used from 1942 to 1945 in the Messerschmitt Bf 109 fighter, and the Bf 110 and Me 210C heavy fighters.

The Daimler-Benz DB 603 was a German aircraft engine used during World War II. It was a liquid-cooled 12-cylinder inverted V12 enlargement of the DB 601, which was in itself a development of the DB 600. Production of the DB 603 commenced in May 1942, and with a 44.5 liter displacement figure, was the largest displacement inverted V12 aviation engine to be produced and used in front line aircraft of the Third Reich during World War II.

The Allison V-3420 was a large experimental piston aircraft engine, designed in 1937 by the American Allison Engine Company.

The Ranger V-770 was an American air-cooled inverted V-12 aircraft engine developed by the Ranger Aircraft Engine Division of the Fairchild Engine & Aircraft Corporation in the early 1930s.

The Wright R-2160 Tornado was an experimental 42-cylinder, 7-cylinder per row, 6-row liquid-cooled inline radial aircraft engine. It was proposed in 1940 with 2,350 hp (1,752 kW) for experimental aircraft such as the Lockheed XP-58 Chain Lightning, Vultee XP-68 Tornado, and the Republic XP-69.

The Rotax 532 is a 48 kW (64 hp) two-stroke, two-cylinder, rotary valve engine, liquid-cooled, gear reduction-drive engine that was formerly manufactured by BRP-Rotax GmbH & Co. KG. It was designed for use on ultralight aircraft.

The Lycoming XH-2470 was an H engine for aircraft designed and developed by Lycoming Engines in the 1930s. Although the engine was flown in an aircraft, it was not fitted to any aircraft selected for production. It was derived from the Lycoming O-1230 engine.

The Lycoming O-1230 was a flat-twelve engine for aircraft designed and developed by Lycoming Engines in the 1930s. Although the engine was flown in an aircraft, it was not fitted to any aircraft selected for production. It later served as the basis for the Lycoming H-2470 engine.

The Kawasaki Ha40, also known as the Army Type 2 1,100 hp Liquid Cooled In-line and Ha-60, was a license-built Daimler-Benz DB 601Aa 12-cylinder liquid-cooled inverted-vee aircraft engine. The Imperial Japanese Army Air Service (IJAAS) selected the engine to power its Kawasaki Ki-61 fighter.