The spinning jenny is a multi-spindle spinning frame, and was one of the key developments in the industrialization of textile manufacturing during the early Industrial Revolution. It was invented in 1764 or 1765 by James Hargreaves in Stanhill, Oswaldtwistle, Lancashire in England.

A power loom is a mechanized loom, and was one of the key developments in the industrialization of weaving during the early Industrial Revolution. The first power loom was designed in 1786 by Edmund Cartwright and first built that same year. It was refined over the next 47 years until a design by the Howard and Bullough company made the operation completely automatic. This device was designed in 1834 by James Bullough and William Kenworthy, and was named the Lancashire loom.

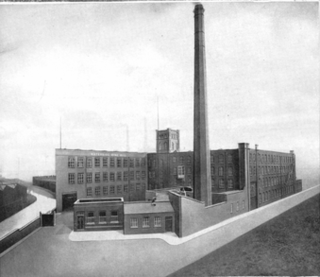

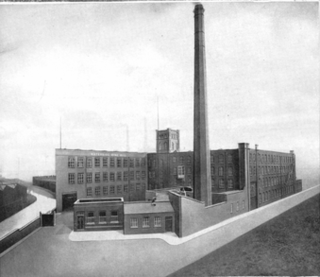

A cotton mill is a building that houses spinning or weaving machinery for the production of yarn or cloth from cotton, an important product during the Industrial Revolution in the development of the factory system.

Textile manufacture during the Industrial Revolution in Britain was centred in south Lancashire and the towns on both sides of the Pennines. In Germany it was concentrated in the Wupper Valley, Ruhr Region and Upper Silesia, in Spain it was concentrated in Catalonia while in the United States it was in New England. The main key drivers of the Industrial Revolution were textile manufacturing, iron founding, steam power, oil drilling, the discovery of electricity and its many industrial applications, the telegraph and many others. Railroads, steam boats, the telegraph and other innovations massively increased worker productivity and raised standards of living by greatly reducing time spent during travel, transportation and communications.

Samuel Greg was a British entrepreneur of the early Industrial Revolution and a pioneer of the factory system. He built Quarry Bank Mill, which at his retirement was the largest textile mill in the country. He and his wife Hannah Greg assumed welfare responsibilities for their employees, many of whom were children, building a model village alongside the factory. At the same time, Greg inherited and operated a slave plantation in the West Indies.

Eccles is a town in Greater Manchester, England, and a part of the City of Salford. Eccles is 2.7 miles (4.3 km) west of Salford and 3.7 miles (6.0 km) west of Manchester city centre, split by the M602 motorway and bordered by the Manchester Ship Canal to the south. The town is famous for the Eccles cake.

Barton Hill is an area of Bristol, just to the east of the city centre and Bristol Temple Meads railway station.

The Amoskeag Manufacturing Company was a textile manufacturer which founded Manchester, New Hampshire, United States. From modest beginnings in near wilderness, it grew throughout the 19th century into the largest cotton textile plant in the world. At its peak, Amoskeag had 17,000 employees and around 30 buildings.

Bagley & Wright was a spinning, doubling and weaving company based in Oldham, Lancashire, England. The business, which was active from 1867 until 1924, 'caught the wave' of the cotton-boom that existed following the end of the American Civil War in 1865 and experienced rapid growth in the United Kingdom and abroad.

Curzon Mill, later known as Alger Mill was a cotton spinning mill in the Hurst district of Ashton-under-Lyne, Greater Manchester, in England. It was built between 1899 and 1902 for the Ashton Syndicate by Sydney Stott of Oldham. It was a sister mill to the Atlas Mill. It was sold to the Alger Spinning Co. Ltd in 1911, and closed in 1942. It was then used as a cigarette factory by the J.A. Pattreiouex company until 1966, and then sold to the Qualitex company for the production of artificial fibres. It was still spinning artificial fibres in the 1990s and was demolished in 1994; the site being used for a housing estate.

Waterside Mill, Ashton-under-Lyne was a combined cotton spinning weaving mill in Whitelands, Ashton-under-Lyne, Greater Manchester, England. It was built as two independent factories. The weaving sheds date from 1857; the four-storey spinning mill dates from 1863. The spinning was taken over by the Lancashire Cotton Corporation in the 1930s. Production finished in 1959. Waterside Mill was converted to electricity around 1911.

Stalybridge Mill, Stalybridge is a cotton spinning mill in Stalybridge, Tameside, Greater Manchester, England. It was built in 1868, and the engine reconfigured in around 1925. It was taken over by the Lancashire Cotton Corporation in the 1930s and passed to Courtaulds in 1964.

Monton Mill was a cotton spinning mill in Eccles, Greater Manchester, England, built in 1906. It was taken over by the Lancashire Cotton Corporation in the 1930s and passed to Courtaulds in 1964. After production ended, it was demolished and replaced with housing; its name is preserved in the street name.

Mars Mill was a former cotton spinning mill in Castleton, Rochdale, Greater Manchester, England. Castleton joined the Borough of Rochdale in 1899. Queensway, Castleton was a hub of cotton mills; Mars, Marland, and Castleton Mill were a group of three. It was taken over by the Lancashire Cotton Corporation in 1935 and passed to Courtaulds in 1964 and demolished in the 1990s; Marland survived until 2004.

Kingston Mill, Stockport is a mid nineteenth century cotton spinning mill in Edgeley, Stockport, Greater Manchester, England. It was taken over by the Lancashire Cotton Corporation in the 1930s and passed to Courtaulds in 1964. Production finished, it was made over to multiple uses.

Harle Syke mill is a weaving shed in Briercliffe on the outskirts of Burnley, Lancashire. It was built on a green field site in 1856, together with terraced houses for the workers. These formed the nucleus of the community of Harle Syke. The village expanded and six other mills were built, including Queen Street Mill.

Hannah Greg was an English diarist significant in the early Industrial Revolution. While her husband Samuel Greg pioneered new ways of running a cloth mill, she supervised the housing and conditions of the employees, including the education of the child workers. The Gregs were considered enlightened employers for the time, and though in the 1830s the apprentice system was questioned, Quarry Bank Mill maintained it until her death.

Tootal is a brand name for a range of British ties, scarves and other garments. The brand is now owned by Coats Viyella. It originates from a textile spinning and manufacturing company established in Manchester in 1799, which later became Tootal Broadhurst Lee, and subsequently Tootal Ltd. The company held patents in crease-resistant fabric.

William Atherton, was a merchant and wealthy landowner from Lancashire, England, who operated and co-owned sugar plantations in the former Colony of Jamaica. He was a slave owner, as well as an importer of slaves from Africa.