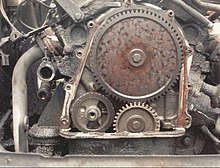

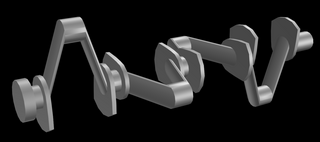

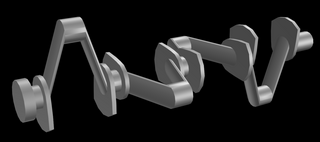

A crankshaft is a mechanical component used in a piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating shaft containing one or more crankpins, that are driven by the pistons via the connecting rods.

A V-twin engine, also called a V2 engine, is a two cylinder piston engine where the cylinders share a common crankshaft and are arranged in a V configuration.

A V6 engine is a six-cylinder piston engine where the cylinders share a common crankshaft and are arranged in a V configuration.

The engine configuration describes the fundamental operating principles by which internal combustion engines are categorized.

A flat engine is a piston engine where the cylinders are located on either side of a central crankshaft. Flat engines are also known as horizontally opposed engines, however this is distinct from the less common opposed-piston engine design, whereby each cylinder has two pistons sharing a central combustion chamber.

A flat-twin engine is a two-cylinder internal combustion engine with the cylinders on opposite sides of the crankshaft. The most common type of flat-twin engine is the boxer-twin engine, where both pistons move inwards and outwards at the same time.

A flat-four engine, also known as a horizontally opposed-four engine, is a four-cylinder piston engine with two banks of cylinders lying on opposite sides of a common crankshaft. The most common type of flat-four engine is the boxer-four engine, each pair of opposed pistons moves inwards and outwards at the same time.

A straight-twin engine, also known as an inline-twin, vertical-twin, or parallel-twin, is a two-cylinder piston engine whose cylinders are arranged in a line along a common crankshaft.

A straight-four engine is a four-cylinder piston engine where cylinders are arranged in a line along a common crankshaft.

A straight-three engine is a three-cylinder piston engine where cylinders are arranged in a line along a common crankshaft.

A U engine is a piston engine made up of two separate straight engines placed side-by-side and coupled to a shared output shaft. When viewed from the front, the engine block resembles the letter "U".

The Honda F-Series engine was considered Honda's "big block" SOHC inline four, though lower production DOHC versions of the F-series were built. It features a solid iron or aluminum open deck cast iron sleeved block and aluminum/magnesium cylinder head.

The Volvo B21 is a slanted straight-four engine first used in the Volvo 200 series, meant to replace the B20. The B21 and all derived engines are often referred to as red block engines for the red paint applied to the block. The primary differences when compared to the B20 was the switch to a SOHC in place of the older pushrod configuration, and an aluminum crossflow cylinder head versus the iron head of the B20.

A motorcycle engine is an engine that powers a motorcycle. Motorcycle engines are typically two-stroke or four-stroke internal combustion engines, but other engine types, such as Wankels and electric motors, have been used.

Engine balance refers to how the forces are balanced within an internal combustion engine or steam engine. The most commonly used terms are primary balance and secondary balance. First-order balance and second-order balance are also used. Unbalanced forces within the engine can lead to vibrations.

The crossplane or cross-plane is a crankshaft design for piston engines with a 90° angle between the crank throws. The crossplane crankshaft is the most popular configuration used in V8 road cars.

A flat-eight engine, also called a horizontally-opposed eight, is an eight-cylinder piston engine with two banks of four inline cylinders, one on each side of a central crankshaft, 180° apart.

A harmonic damper is a device fitted to the free end of the crankshaft of an internal combustion engine to counter torsional and resonance vibrations from the crankshaft. This device must be an interference fit to the crankshaft in order to operate in an effective manner. An interference fit ensures the device moves in perfect step with the crankshaft. It is essential on engines with long crankshafts and V8 engines with cross plane cranks, or V6 and straight-three engines with uneven firing order. Harmonics and torsional vibrations can greatly reduce crankshaft life, or cause instantaneous failure if the crankshaft runs at or through an amplified resonance. Dampers are designed with a specific weight (mass) and diameter, which are dependent on the damping material/method used, to reduce mechanical Q factor, or damp, crankshaft resonances.

A big bang engine is an unconventional engine designed so that some of the power strokes occur simultaneously or in close succession. This is achieved by changing the ignition timing, changing or re-timing the camshaft, and sometimes in combination with a change in crankpin angle. The goal is to change the power delivery characteristics of the engine. A regular firing multi-cylinder engine fires at approximately even intervals, giving a smooth-running engine. Because a big-bang engine has uneven power delivery, they tend to run rougher and generate more vibration than an even-firing engine.

The Michel engine was an unusual form of opposed-piston engine. It was unique in that its cylinders, instead of being open-ended cylinders containing two pistons, were instead joined in a Y-shape and had three pistons working within them.