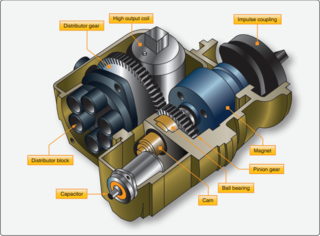

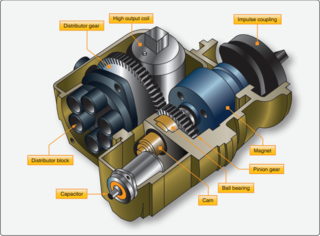

An ignition magneto is an older type of ignition system used in spark-ignition engines. It uses a magneto and a transformer to make pulses of high voltage for the spark plugs. The older term "high-tension" means "high-voltage".

An alternator is an electrical generator that converts mechanical energy to electrical energy in the form of alternating current. For reasons of cost and simplicity, most alternators use a rotating magnetic field with a stationary armature. Occasionally, a linear alternator or a rotating armature with a stationary magnetic field is used. In principle, any AC electrical generator can be called an alternator, but usually the term refers to small rotating machines driven by automotive and other internal combustion engines.

Engine tuning is the adjustment or modification of the internal combustion engine or Engine Control Unit (ECU) to yield optimal performance and increase the engine's power output, economy, or durability. These goals may be mutually exclusive; an engine may be de-tuned with respect to output power in exchange for better economy or longer engine life due to lessened stress on engine components.

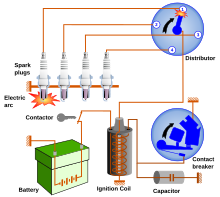

Ignition systems are used by heat engines to initiate combustion by igniting the fuel-air mixture. In a spark ignition versions of the internal combustion engine, the ignition system creates a spark to ignite the fuel-air mixture just before each combustion stroke. Gas turbine engines and rocket engines normally use an ignition system only during start-up.

A contact breaker is a type of electrical switch, found in the ignition systems of spark-ignition internal combustion engines. The switch is automatically operated by a cam driven by the engine. The timing of operation of the switch is set so that a spark is produced at the right time to ignite the compressed air/fuel mixture in the cylinder of the engine. A mechanism may be provided to slightly adjust timing to allow for varying load on the engine. Since these contacts operate frequently, they are subject to wear, causing erratic ignition of the engine. More recent engines use electronic means to trigger the spark, which eliminated contact wear and allows computer control of ignition timing.

A W8 engine is an eight-cylinder piston engine with four banks of two cylinders each, arranged in a W configuration.

A wasted spark system is a type of ignition system used in some four-stroke cycle internal combustion engines. In a wasted spark system, the spark plugs fire in pairs, with one plug in a cylinder on its compression stroke and the other plug in a cylinder on its exhaust stroke. The extra spark during the exhaust stroke has no effect and is thus "wasted". This design halves the number of components necessary in a typical ignition system, while the extra spark, against much reduced dielectric resistance, barely impacts the lifespan of modern ignition components. In a typical engine, it requires only about 2–3 kV to fire the cylinder on its exhaust stroke. The remaining coil energy is available to fire the spark plug in the cylinder on its compression stroke.

High energy ignition, also known as H.E.I., is an electronic ignition system designed by the Delco-Remy Division of General Motors. It was used on all GM vehicles, at least in the North American market, from 1975 through the mid-1980s. There were many design variations over the years, and provisions for computer controls were added for some applications starting in the late 1970s. A predecessor system called "Unitized Ignition" was optional on 1972 and 1973 Pontiacs.

Alfa Romeo Twin Spark (TS) technology was used for the first time in the Alfa Romeo Grand Prix car in 1914. In the early 1960s it was used in their race cars (GTA, TZ) to enable it to achieve a higher power output from its engines. And in the early and middle 1980s, Alfa Romeo incorporated this technology into their road cars to enhance their performance and to comply with stricter emission controls.

An ignition coil is used in the ignition system of a spark-ignition engine to transform the battery voltage to the much higher voltages required to operate the spark plug(s). The spark plugs then use this burst of high-voltage electricity to ignite the air-fuel mixture.

Capacitor discharge ignition (CDI) or thyristor ignition is a type of automotive electronic ignition system which is widely used in outboard motors, motorcycles, lawn mowers, chainsaws, small engines, turbine-powered aircraft, and some cars. It was originally developed to overcome the long charging times associated with high inductance coils used in inductive discharge ignition (IDI) systems, making the ignition system more suitable for high engine speeds. The capacitive-discharge ignition uses capacitor to discharge current to the ignition coil to fire the spark plugs.

In a spark ignition internal combustion engine, ignition timing is the timing, relative to the current piston position and crankshaft angle, of the release of a spark in the combustion chamber near the end of the compression stroke.

A hit-and-miss engine or Hit 'N' Miss is a type of stationary internal combustion engine that is controlled by a governor to only fire at a set speed. They are usually 4-stroke but 2-stroke versions were made. It was conceived in the late 19th century and produced by various companies from the 1890s through approximately the 1940s. The name comes from the speed control on these engines: they fire ("hit") only when operating at or below a set speed, and cycle without firing ("miss") when they exceed their set speed. This is as compared to the "throttle governed" method of speed control. The sound made when the engine is running without a load is a distinctive "Snort POP whoosh whoosh whoosh whoosh snort POP" as the engine fires and then coasts until the speed decreases and it fires again to maintain its average speed. The snorting is caused by the atmospheric intake valve used on many of these engines.

Trionic T5.5 is an engine management system in the Saab Trionic range. It controls ignition, fuel injection and turbo boost pressure. The system was introduced in the 1993 Saab 9000 2.3 Turbo with B234L and B234R engine.

Spark plug wires are electrical cables used by older internal combustion engines to transmit high-voltage electricity from the distributor to the spark plugs. Tension in this instance is a synonym for voltage. High tension may also be referred to as HT.

The Delco ignition system, also known as the Kettering ignition system, points and condenser ignition or breaker point ignition, is a type of inductive discharge ignition system invented by Charles F. Kettering. It was first sold commercially on the 1912 Cadillac and was manufactured by Delco. Over time, it was used extensively by all automobile and truck manufacturers on spark ignition, i.e., gasoline engines. Today it is still widely used in coil-on-plug, coil-near-plug and in coil packs in distributorless ignitions. An alternative system used in automobiles is capacitor discharge ignition, primarily found now as aftermarket upgrade systems. Electronic ignition was a common term for Kettering inductive ignition with the points replaced with an electronic switch such as a transistor.

A magneto is an electrical generator that uses permanent magnets to produce periodic pulses of alternating current. Unlike a dynamo, a magneto does not contain a commutator to produce direct current. It is categorized as a form of alternator, although it is usually considered distinct from most other alternators, which use field coils rather than permanent magnets.

The Austin 25-30 is a motor car. It was the first automobile produced by newly established British car manufacturer Austin.

A trembler coil, buzz coil or vibrator coil is a type of high-voltage ignition coil used in the ignition system of early automobiles, most notably the Benz Patent-Motorwagen and the Ford Model T. Its distinguishing feature is a vibrating magnetically-activated contact called a trembler or interrupter, which breaks the primary current, generating multiple sparks during each cylinder's power stroke. Trembler coils were first used on the 1886 Benz automobile, and were used on the Model T until 1927.