An intercooler is a heat exchanger used to cool a gas after compression. [1] Often found in turbocharged engines, intercoolers are also used in air compressors, air conditioners, refrigeration and gas turbines.

An intercooler is a heat exchanger used to cool a gas after compression. [1] Often found in turbocharged engines, intercoolers are also used in air compressors, air conditioners, refrigeration and gas turbines.

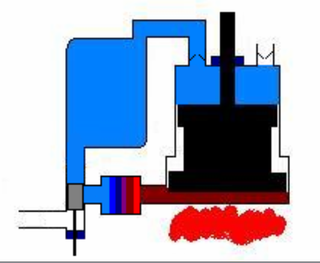

Most commonly used with turbocharged engines, an intercooler is used to counteract the heat of compression and heat soak in the pressurised intake air. By reducing the temperature of the intake air, the air becomes denser (allowing more fuel to be injected, resulting in increased power) and less likely to suffer from pre-ignition or knocking. Additional cooling can be provided by externally spraying a fine mist onto the intercooler surface, or even into the intake air itself, to further reduce intake charge temperature through evaporative cooling.

Intercoolers can vary dramatically in size, shape and design, depending on the performance and space requirements of the system. Many passenger cars use either front-mounted intercoolers located in the front bumper or grill opening, or top-mounted intercoolers located above the engine. An intercooling system can use an air-to-air design, an air-to-liquid design, or a combination of both.

In automotive engines where multiple stages of forced-induction are used (e.g. a sequential twin-turbo or twin-charged engine), the intercooling usually takes place after the last turbocharger/supercharger. However it is also possible to use separate intercoolers for each stage of the turbocharging/supercharging, such as in the JCB Dieselmax land speed record racing car. Some aircraft engines also use an intercooler for each stage of the forced induction.[ citation needed ] In engines with two-stage turbocharging, the term intercooler can specifically refer to the cooler between the two turbochargers and the term aftercooler is used for the cooler located between the second-stage turbo and the engine. However, the terms intercooler and charge-air cooler are also often used regardless of the location in the intake system. [2]

Air-to-air intercoolers are heat exchangers that transfer heat from the intake air directly to the atmosphere. Alternatively, air-to-liquid intercoolers transfer the heat from the intake air to intermediate liquid (usually water), which in turn transfers the heat to the atmosphere. The heat exchanger that transfers the heat from the fluid to the atmosphere operates in a similar fashion to the main radiator in a water-cooled engine's cooling system, or in some cases the engine's cooling system is also used for the intercooling system. Air-to-liquid intercoolers are usually heavier than their air-to-air counterparts, due to additional components making up the system (e.g. water circulation pump, radiator, fluid, and plumbing).

The majority of marine engines use air-to-liquid intercoolers, since the water of the lake, river or sea can easily be accessed for cooling purposes. In addition, most marine engines are located in closed compartments where obtaining a good flow of cooling air for an air-to-air unit would be difficult. Marine intercoolers take the form of a tubular heat exchanger with the air passing around a series of tubes within the cooler casing, and sea water circulating inside the tubes. The main materials used for this kind of application are meant to resist sea water corrosion: Copper-Nickel for the tubes and bronze for the sea water covers.

An alternative to using intercoolers - which is rarely used these days - was to inject excess fuel into the combustion chamber, so that the vaporization process would cool the cylinders in order to prevent knocking. However the downsides to this method were increased fuel consumption and exhaust gas emissions. [3]

Intercoolers are used to remove the waste heat from the first stage of two-stage air compressors. Two-stage air compressors are manufactured because of their inherent efficiency. The cooling action of the intercooler is principally responsible for this higher efficiency, bringing it closer to Carnot efficiency. Removing the heat-of-compression from the discharge of the first stage has the effect of densifying the air charge. This, in turn, allows the second stage to produce more work from its fixed compression ratio. Adding an intercooler to the setup requires additional investments.

In an internal combustion engine, a turbocharger is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake air, forcing more air into the engine in order to produce more power for a given displacement.

In engineering, the Miller cycle is a thermodynamic cycle used in a type of internal combustion engine. The Miller cycle was patented by Ralph Miller, an American engineer, U.S. Patent 2,817,322 dated Dec 24, 1957. The engine may be two- or four-stroke and may be run on diesel fuel, gases, or dual fuel.

The Roots-type blower is a positive displacement lobe pump which operates by pumping a fluid with a pair of meshing lobes resembling a set of stretched gears. Fluid is trapped in pockets surrounding the lobes and carried from the intake side to the exhaust. The most common application of the Roots-type blower has been the induction device on two-stroke diesel engines, such as those produced by Detroit Diesel and Electro-Motive Diesel. Roots-type blowers are also used to supercharge four-stroke Otto cycle engines, with the blower being driven from the engine's crankshaft via a toothed or V-belt, a roller chain or a gear train.

A centrifugal supercharger is a specialized type of supercharger that makes use of centrifugal force in order to increase the manifold air pressure, MAP. An increased MAP allows the engine to burn more fuel, which results in an increased power output. Centrifugal superchargers are generally attached to the front of the engine via a belt-drive or gear-drive from the engine's crankshaft.

The Brayton cycle is a thermodynamic cycle that describes the operation of certain heat engines that have air or some other gas as their working fluid. The original Brayton engines used a piston compressor and piston expander, but modern gas turbine engines and airbreathing jet engines also follow the Brayton cycle. Although the cycle is usually run as an open system, it is conventionally assumed for the purposes of thermodynamic analysis that the exhaust gases are reused in the intake, enabling analysis as a closed system.

Compressed-air energy storage (CAES) is a way to store energy for later use using compressed air. At a utility scale, energy generated during periods of low demand can be released during peak load periods.

A compressor is a mechanical device that increases the pressure of a gas by reducing its volume. An air compressor is a specific type of gas compressor.

In an internal combustion engine, forced induction is where turbocharging or supercharging is used to increase the density of the intake air. Engines without forced induction are classified as naturally aspirated.

SABRE is a concept under development by Reaction Engines Limited for a hypersonic precooled hybrid air-breathing rocket engine. The engine is being designed to achieve single-stage-to-orbit capability, propelling the proposed Skylon spaceplane to low Earth orbit. SABRE is an evolution of Alan Bond's series of LACE-like designs that started in the early/mid-1980s for the HOTOL project.

Internal combustion engine cooling uses either air or liquid to remove the waste heat from an internal combustion engine. For small or special purpose engines, cooling using air from the atmosphere makes for a lightweight and relatively simple system. Watercraft can use water directly from the surrounding environment to cool their engines. For water-cooled engines on aircraft and surface vehicles, waste heat is transferred from a closed loop of water pumped through the engine to the surrounding atmosphere by a radiator.

The Ericsson cycle is named after inventor John Ericsson who designed and built many unique heat engines based on various thermodynamic cycles. He is credited with inventing two unique heat engine cycles and developing practical engines based on these cycles. His first cycle is now known as the closed Brayton cycle, while his second cycle is what is now called the Ericsson cycle. Ericsson is one of the few who built open-cycle engines, but he also built closed-cycle ones.

A blowoff valve is a pressure release system present in most petrol turbocharged engines. Blowoff valves are used to reduce pressure in the intake system as the throttle is closed, thus preventing compressor surge.

The precooled jet engine is a concept that enables jet engines with turbomachinery, as opposed to ramjets, to be used at high speeds. Precooling restores some or all of the performance degradation of the engine compressor, as well as that of the complete gas generator, which would otherwise prevent flight with high ram temperatures.

Twin-turbo refers to an engine in which two turbochargers work in tandem to compress the intake fuel/air mixture. The most common layout features two identical or mirrored turbochargers in parallel, each processing half of a V engine's produced exhaust through independent piping. The two turbochargers can either be matching or different sizes.

Economizers, or economisers (UK), are mechanical devices intended to reduce energy consumption, or to perform useful function such as preheating a fluid. The term economizer is used for other purposes as well. Boiler, power plant, heating, refrigeration, ventilating, and air conditioning (HVAC) uses are discussed in this article. In simple terms, an economizer is a heat exchanger.

The term turbo-diesel, also written as turbodiesel and turbo diesel, refers to any diesel engine equipped with a turbocharger. As with other engine types, turbocharging a diesel engine can significantly increase its efficiency and power output, especially when used in combination with an intercooler.

In an internal combustion engine, a supercharger compresses the intake gas, forcing more air into the engine in order to produce more power for a given displacement.

A coolpower setup in a truck engine can use an aftercooler mounted on top of the engine with a tip turbine fan, or an air-to-air cooler in front of the radiator. In either case, the goal is to cool the hot, compressed air going from the turbocharger into the engine. With the tip turbine, a small quantity of compressed air is bled off to spin a small fan that draws air through the aftercooler tubes. In some later models, a water cooler was also used, in addition to the tip turbine setup. Mack called the tip-turbine setup an intercooler and used a pyrometer to alert the operator if the exhaust gas exceeded a limit. The tip turbine setup was compact and the shorter plumbing runs allowed boost to build faster. Later models with the front mounted air-to-air cooler required a larger turbocharger to fill the tubes faster but with the benefit of additional power. Modern trucks use the air-to-air cooler in nearly all cases.

Radiators are heat exchangers used for cooling internal combustion engines, mainly in automobiles but also in piston-engined aircraft, railway locomotives, motorcycles, stationary generating plant or any similar use of such an engine.

An internal combustion engine is a heat engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons, turbine blades, a rotor, or a nozzle. This force moves the component over a distance, transforming chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to.