A clutch is a mechanical device that allows the output shaft to be disconnected from the rotating input shaft. The clutch's input shaft is typically attached to a motor, while the clutch's output shaft is connected to the mechanism that does the work.

A gear is a rotating circular machine part having cut teeth or, in the case of a cogwheel or gearwheel, inserted teeth, which mesh with another (compatible) toothed part to transmit (convert) torque and speed. The basic principle behind the operation of gears is analogous to the basic principle of levers. A gear may also be known informally as a cog. Geared devices can change the speed, torque, and direction of a power source. Gears of different sizes produce a change in torque, creating a mechanical advantage, through their gear ratio, and thus may be considered a simple machine. The rotational speeds, and the torques, of two meshing gears differ in proportion to their diameters. The teeth on the two meshing gears all have the same shape.

A starter is a device used to rotate (crank) an internal-combustion engine so as to initiate the engine's operation under its own power. Starters can be electric, pneumatic, or hydraulic. The starter can also be another internal-combustion engine in the case, for instance, of very large engines, or diesel engines in agricultural or excavation applications.

A differential is a gear train with three drive shafts that has the property that the rotational speed of one shaft is the average of the speeds of the others, or a fixed multiple of that average.

A continuously variable transmission (CVT) is an automatic transmission that can change seamlessly through a continuous range of gear ratios. This contrasts with other transmissions that provide a limited number of gear ratios in fixed steps. The flexibility of a CVT with suitable control may allow the engine to operate at a constant RPM while the vehicle moves at varying speeds.

A manual transmission (MT), also known as manual gearbox, standard transmission, or stick shift, is a multi-speed motor vehicle transmission system, where gear changes require the driver to manually select the gears by operating a gear stick and clutch.

In mechanical or automotive engineering, a freewheel or overrunning clutch is a device in a transmission that disengages the driveshaft from the driven shaft when the driven shaft rotates faster than the driveshaft. An overdrive is sometimes mistakenly called a freewheel, but is otherwise unrelated.

The Mercedes Simplex was an automobile produced from 1902 to 1909 by the Daimler Motoren Gesellschaft. It continued the use of the Mercedes name as the brand of DMG, rather than Daimler.

Vehicles made by American Motors Corporation (AMC) and Jeep incorporated a variety of transmissions and transfer case systems. This article covers transmissions used in the following vehicle models and years:

A starter solenoid is an electromagnet which is actuated to engage the starter motor of an internal combustion engine. It is normally attached directly to the starter motor which it controls.

Chevrolet Corvair Powerglide is a two-speed automatic transmission designed specially for the then all-new 1960 Chevrolet Corvair compact car that emerged in the fall of 1959 as Chevrolet's competitor in the then booming small car market. The Corvair was powered by a rear-mounted Chevrolet Turbo-Air 6 engine that necessitated a specially designed transaxle. Corvair Powerglide took the principles of the standard Chevrolet Powerglide and modified them to suit the rear-mounted powertrain location of the new Corvair. The Corvair used the Powerglide for all 10 years it was produced; from 1961 to 1963, Pontiac used a modified version of Corvair Powerglide it called 'TempesTorque' for its front-engine, rear-transaxle Tempest, LeMans and Tempest LeMans cars.

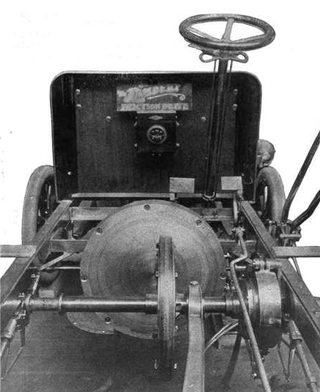

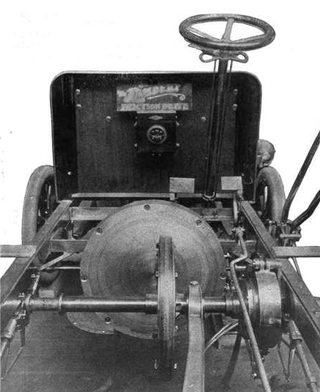

The Lambert automobile and Lambert truck were vehicles built from 1905 through 1916 by the Lambert Automobile Company in Anderson, Indiana, United States. The Lambert automobile was an outgrowth from the Union automobile made by the Union Automobile Company, a previous vehicle that was being manufactured by John William Lambert. The factory manufactured about 3,000 automobiles and trucks per year by 1915 and had several models ranging in price from $1,200 to $3,000 at the time. The vehicles came with a gearless friction drive transmission. The demise of the manufacture of automobiles and trucks came about because of World War I.

A vehicle frame, also historically known as its chassis, is the main supporting structure of a motor vehicle to which all other components are attached, comparable to the skeleton of an organism.

A spiral bevel gear is a bevel gear with helical teeth. The main application of this is in a vehicle differential, where the direction of drive from the drive shaft must be turned 90 degrees to drive the wheels. The helical design produces less vibration and noise than conventional straight-cut or spur-cut gear with straight teeth.

The Lambert friction transmission was a mechanism devised and patented by John W. Lambert in 1904. It was a mechanical transmission that consisted of a friction wheel pressed against the back of the automobile motor flywheel main disk by a pedal controlled by the driver's foot. It was a type of clutch. When the pedal pressure was released the friction wheel could be moved across the power flywheel disk to provide a different ratio to give a driving speed as high or as low as desired; it even went into reverse to help decelerate while going forward or for driving backwards. The transmission was used in all of the vehicles manufactured by Lambert.

A barring engine is a small engine that forms part of the installation of a large engine, and is used to turn the main engine to a favourable position from which it can be started. If the main engine has stopped close to its dead centre it is unable to restart itself. Barring may also be done to turn the engine over slowly (unloaded) for maintenance, or to prevent belt drives being left too long in one position and taking a "set".

A Bendix drive is a type of engagement mechanism used in starter motors of internal combustion engines. The device allows the pinion gear of the starter motor to engage or disengage the ring gear automatically when the starter is powered or when the engine fires, respectively. It is named after its inventor, Vincent Hugo Bendix.

A flexplate is a metal disk that connects the output from an engine to the input of a torque converter in a car equipped with an automatic transmission. It takes the place of the flywheel found in a conventional manual transmission setup. The name refers to the ability of the disk to flex across its main axis – bending side to side – to take up motion in the torque converter as rotational speeds change. Flexplates are generally much thinner and lighter than flywheels due to the smooth coupling action of the torque converter and the elimination of the clutch surface. Like flywheels, flexplates normally handle coupling to the starter motor, via teeth cut along the outer edge of the plate. These teeth give the flexplate a gear-like appearance, in spite of this being a secondary function. Flexplates come in many forms, but are usually either stamped steel, a two-piece billet or a one-piece billet.

There are numerous versions of vehicle propulsion systems. Many of those came into fruition due to need for cleaner vehicles. Each of them might have many abbreviations and some might be misleading. This article explains shortly what defines them.