A boiler is a closed vessel in which fluid is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation.

A fire-tube boiler is a type of boiler in which hot gases pass from a fire through one or more tubes running through a sealed container of water. The heat of the gases is transferred through the walls of the tubes by thermal conduction, heating the water and ultimately creating steam.

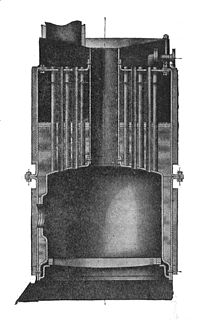

A high pressure watertube boiler is a type of boiler in which water circulates in tubes heated externally by the fire. Fuel is burned inside the furnace, creating hot gas which boils water in the steam-generating tubes. In smaller boilers, additional generating tubes are separate in the furnace, while larger utility boilers rely on the water-filled tubes that make up the walls of the furnace to generate steam.

In a steam engine, the firebox is the area where the fuel is burned, producing heat to boil the water in the boiler. Most are somewhat box-shaped, hence the name. The hot gases generated in the firebox are pulled through a rack of tubes running through the boiler.

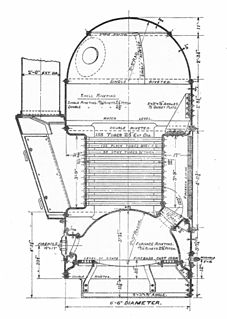

The Belpaire firebox is a type of firebox used on steam locomotives. It was invented by Alfred Belpaire of Belgium in 1864. Today it generally refers to the shape of the outer shell of the firebox which is approximately flat at the top and square in cross-section, indicated by the longitudinal ridges on the top sides. However, it is the similar square cross-section inner firebox which provides the main advantages of this design i.e. it has a greater surface area at the top of the firebox where the heat is greatest, improving heat transfer and steam production, compared with a round-top shape.

The LNER Class Y1 was a class of 0-4-0 geared steam locomotives built by Sentinel Waggon Works for the London and North Eastern Railway and introduced in 1925. They passed into British Railways ownership in 1948 and were numbered 68130-68153 but 68134 was withdrawn almost immediately and may not have carried its BR number.

The LNER Class Y3 was a class of 0-4-0 geared steam locomotives built by Sentinel Waggon Works for the London and North Eastern Railway and introduced in 1927. They passed into British Railways ownership in 1948 and were numbered 68154-68185. At least one was based at Immingham in 1950.

The LNER Class Y10 was a class of two 0-4-0T geared steam locomotives built by Sentinel Waggon Works for the London and North Eastern Railway and introduced in 1930. The LNER numbered them 8403 and 8404 but they were later re-numbered 8186 and 8187. This was the second use of the classification Y10 by the LNER. The first was for an ex-North British Railway 0-4-0 steam tender locomotive, withdrawn 1925.

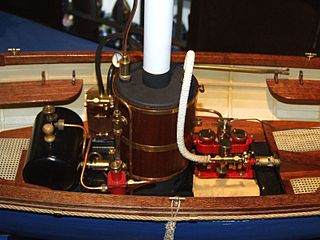

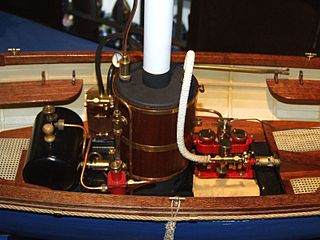

A vertical boiler is a type of fire-tube or water-tube boiler where the boiler barrel is oriented vertically instead of the more common horizontal orientation. Vertical boilers were used for a variety of steam-powered vehicles and other mobile machines, including early steam locomotives.

A shell or flued boiler is an early and relatively simple form of boiler used to make steam, usually for the purpose of driving a steam engine. The design marked a transitional stage in boiler development, between the early haystack boilers and the later multi-tube fire-tube boilers. A flued boiler is characterized by a large cylindrical boiler shell forming a tank of water, traversed by one or more large flues containing the furnace. These boilers appeared around the start of the 19th century and some forms remain in service today. Although mostly used for static steam plants, some were used in early steam vehicles, railway locomotives and ships.

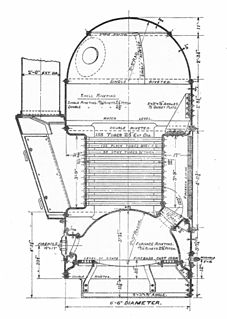

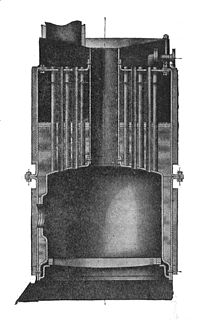

A vertical boiler with horizontal fire-tubes is a type of small vertical boiler, used to generate steam for small machinery. It is characterised by having many narrow fire-tubes, running horizontally.

Yarrow boilers are an important class of high-pressure water-tube boilers. They were developed by Yarrow & Co. (London), Shipbuilders and Engineers and were widely used on ships, particularly warships.

Boilers for generating steam or hot water have been designed in countless shapes, sizes and configurations. An extensive terminology has evolved to describe their common features. This glossary provides definitions for these terms.

Three-drum boilers are a class of water-tube boiler used to generate steam, typically to power ships. They are compact and of high evaporative power, factors that encourage this use. Other boiler designs may be more efficient, although bulkier, and so the three-drum pattern was rare as a land-based stationary boiler.

A transverse boiler is a boiler used to generate steam to power a vehicle. Unlike other boilers, its external drum is mounted transversely across the vehicle.

A vertical fire-tube boiler or vertical multitubular boiler is a vertical boiler where the heating surface is composed of multiple small fire-tubes, arranged vertically.

A launch-type, gunboat or horizontal multitubular boiler is a form of small steam boiler. It consists of a cylindrical horizontal shell with a cylindrical furnace and fire-tubes within this.

The South African Railways Class 10B 4-6-2 of 1910 was a steam locomotive from the pre-Union era in Transvaal.

A thimble tube boiler is a form of steam boiler, usually provided as an auxiliary boiler or heat-recovery boiler. They are vertical in orientation and would be considered a form of water-tube boiler.

The Reed water tube boiler was a type of water tube boiler developed by J. W. Reed, manager of the engine works at Palmers Shipbuilding and Iron Company of Jarrow, England, where it was manufactured from 1893 to 1905. At this time, Palmers was a vertically integrated business: in its shipyard at Jarrow, using iron ore from its own mine in North Yorkshire, it produced the iron and steel needed for its ships, and engines and boilers of its own design.