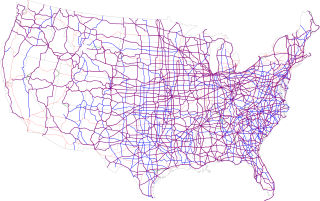

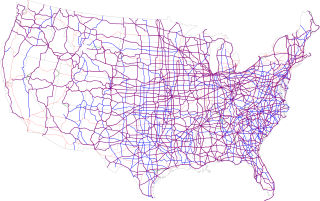

The United States Numbered Highway System is an integrated network of roads and highways numbered within a nationwide grid in the contiguous United States. As the designation and numbering of these highways were coordinated among the states, they are sometimes called Federal Highways, but the roadways were built and have always been maintained by state or local governments since their initial designation in 1926.

Highway engineering is a professional engineering discipline branching from the civil engineering subdiscipline of transportation engineering that involves the planning, design, construction, operation, and maintenance of roads, highways, streets, bridges, and tunnels to ensure safe and effective transportation of people and goods. Highway engineering became prominent towards the latter half of the 20th century after World War II. Standards of highway engineering are continuously being improved. Highway engineers must take into account future traffic flows, design of highway intersections/interchanges, geometric alignment and design, highway pavement materials and design, structural design of pavement thickness, and pavement maintenance.

A road surface or pavement is the durable surface material laid down on an area intended to sustain vehicular or foot traffic, such as a road or walkway. In the past, gravel road surfaces, macadam, hoggin, cobblestone and granite setts were extensively used, but these have mostly been replaced by asphalt or concrete laid on a compacted base course. Asphalt mixtures have been used in pavement construction since the beginning of the 20th century and are of two types: metalled (hard-surfaced) and unmetalled roads. Metalled roadways are made to sustain vehicular load and so are usually made on frequently used roads. Unmetalled roads, also known as gravel roads or dirt roads, are rough and can sustain less weight. Road surfaces are frequently marked to guide traffic.

The American Association of State Highway and Transportation Officials (AASHTO) is a standards setting body which publishes specifications, test protocols, and guidelines that are used in highway design and construction throughout the United States. Despite its name, the association represents not only highways but air, rail, water, and public transportation as well.

A dipstick is one of several measurement devices.

The Minnesota Road Research Facility, is an outdoor research laboratory operated by the Minnesota Department of Transportation (MnDOT) that specializes in testing different types of pavement. Said to be the largest such facility in the world, it is located 40 miles (64 km) northwest of Minneapolis-St. Paul near the town of Albertville along Interstate 94 (I-94). Minnesota is a good site for such a project, as the state experiences some of the largest seasonal swings in temperature in the United States, and has a spring freeze–thaw cycle that can heavily damage roadways. More than 4,500 sensors are embedded in and under the road surfaces to measure stresses while the test segments are in use. The facility was constructed from 1990 through 1993 at a cost of $25 million and opened in 1994. It earned an Award of Merit in the Federal Highway Administration's 1996 Excellence in Highway Design competition.

Standards for Interstate Highways in the United States are defined by the American Association of State Highway and Transportation Officials (AASHTO) in the publication A Policy on Design Standards: Interstate System. For a certain highway to be considered an Interstate Highway, it must meet these construction requirements or obtain a waiver from the Federal Highway Administration.

Weigh-in-motion or weighing-in-motion (WIM) devices are designed to capture and record the axle weights and gross vehicle weights as vehicles drive over a measurement site. Unlike static scales, WIM systems are capable of measuring vehicles traveling at a reduced or normal traffic speed and do not require the vehicle to come to a stop. This makes the weighing process more efficient, and, in the case of commercial vehicles, allows for trucks under the weight limit to bypass static scales or inspection.

Annual average daily traffic (AADT) is a measure used primarily in transportation planning, transportation engineering and retail location selection. Traditionally, it is the total volume of vehicle traffic of a highway or road for a year divided by 365 days. AADT is a simple, but useful, measurement of how busy the road is.

The pavement condition index (PCI) is a numerical index between 0 and 100, which is used to indicate the general condition of a pavement section. The PCI is widely used in transportation civil engineering and asset management, and many municipalities use it to measure the performance of their road infrastructure and their levels of service. It is a statistical measure and requires manual survey of the pavement. This index was originally developed by the United States Army Corps of Engineers as an airfield pavement rating system, but later modified for roadway pavements and standardized by the ASTM. The surveying processes and calculation methods have been documented and standardized by ASTM for both roads and airport pavements:

Interstate 795 (I-795) is a 25.49-mile (41.02 km) auxiliary Interstate Highway in the US state of North Carolina. It connects the city of Goldsboro to I-95 just south of Wilson, paralleling the northern portion of US Route 117 (US 117). The road runs a five-mile (8.0 km) concurrency with US 264 and I-587 in the last section of the route. It serves as a primary freeway spur for the city of Goldsboro to the Interstate Highway System, as well part of a major cargo route for the cities of Down East, which was a part of the impetus for its designation in 2007. Future plans call for the interstate to be further extended southward to meet I-40 near Faison.

The Federal Bridge Gross Weight Formula, also known as Bridge Formula B or the Federal Bridge Formula, is a mathematical formula in use in the United States by truck drivers and Department of Transportation (DOT) officials to determine the appropriate maximum gross weight for a commercial motor vehicle (CMV) based on axle number and spacing. The formula is part of federal weight and size regulations regarding interstate commercial traffic. The formula is necessary to prevent heavy vehicles from damaging roads and bridges. CMVs are most often tractor-trailers or buses, but the formula is of most interest to truck drivers due to the heavy loads their vehicles often carry.

Road surface textures are deviations from a planar and smooth surface, affecting the vehicle/tyre interaction. Pavement texture is divided into: microtexture with wavelengths from 0 mm to 0.5 millimetres (0.020 in), macrotexture with wavelengths from 0.5 millimetres (0.020 in) to 50 millimetres (2.0 in) and megatexture with wavelengths from 50 millimetres (2.0 in) to 500 millimetres (20 in).

The international roughness index (IRI) is the roughness index most commonly obtained from measured longitudinal road profiles. It is calculated using a quarter-car vehicle math model, whose response is accumulated to yield a roughness index with units of slope. Although a universal term, IRI is calculated per wheelpath, but can be expanded to a Mean Roughness Index (MRI) when both wheelpath profiles are collected. This performance measure has less stochasticity and subjectivity in comparison to other pavement performance indicators, such as PCI, but it is not completely devoid of randomness. The sources of variability in IRI data include the difference among the readings of different runs of the test vehicle and the difference between the readings of the right and left wheel paths. Despite these facts, since its introduction in 1986, the IRI has become the road roughness index most commonly used worldwide for evaluating and managing road systems.

Long-Term Pavement Performance Program, known as LTPP, is a research project supported by Federal Highway Administration (FHWA) to collect and analyze pavement data in the United States and Canada. Currently, the LTPP acquires the largest road performance database.

Pavement performance modeling or pavement deterioration modeling is the study of pavement deterioration throughout its life-cycle. The health of pavement is assessed using different performance indicators. Some of the most well-known performance indicators are Pavement Condition Index (PCI), International Roughness Index (IRI) and Present Serviceability Index (PSI), but sometimes a single distress such as rutting or the extent of crack is used. Among the most frequently used methods for pavement performance modeling are mechanistic models, mechanistic-empirical models, survival curves and Markov models. Recently, machine learning algorithms have been used for this purpose as well. Most studies on pavement performance modeling are based on IRI.

Vehicle weight is a measurement of wheeled motor vehicles; either an actual measured weight of the vehicle under defined conditions or a gross weight rating for its weight carrying capacity.

The present serviceability index (PSI) is a pavement performance measure. Introduced by the American Association of State Highway and Transportation Officials (AASHTO), the PSI is one of the most widely used pavement performance indicators after pavement condition index (PCI) and international roughness index (IRI). This performance indicator ranges between 0 and 5, 0 representing a failed pavement and 5 an excellent one. Since the PSI entails slope variance, it is correlated with performance indicators related to roughness such as IRI.

The fourth power law states that the stress on the road caused by a motor vehicle increases in proportion to the fourth power of its axle load. This law was discovered in the course of a series of scientific experiments in the United States in the late 1950s and was decisive for the development of standard construction methods in road construction.