Related Research Articles

Biofuel is a fuel that is produced over a short time span from biomass, rather than by the very slow natural processes involved in the formation of fossil fuels, such as oil. Biofuel can be produced from plants or from agricultural, domestic or industrial biowaste. The climate change mitigation potential of biofuel varies considerably, from emission levels comparable to fossil fuels in some scenarios to negative emissions in others. Biofuels are mostly used for transportation, but can also be used for heating and electricity. Biofuels are regarded as a renewable energy source.

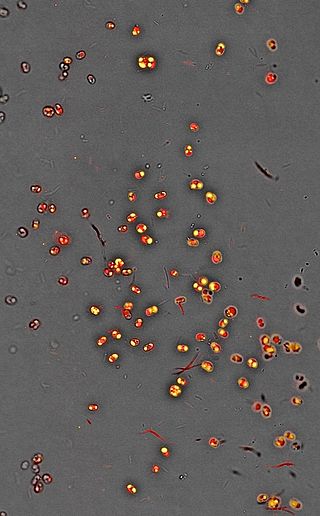

Microalgae or microphytes are microscopic algae invisible to the naked eye. They are phytoplankton typically found in freshwater and marine systems, living in both the water column and sediment. They are unicellular species which exist individually, or in chains or groups. Depending on the species, their sizes can range from a few micrometers (μm) to a few hundred micrometers. Unlike higher plants, microalgae do not have roots, stems, or leaves. They are specially adapted to an environment dominated by viscous forces.

Cellulosic ethanol is ethanol produced from cellulose rather than from the plant's seeds or fruit. It can be produced from grasses, wood, algae, or other plants. It is generally discussed for use as a biofuel. The carbon dioxide that plants absorb as they grow offsets some of the carbon dioxide emitted when ethanol made from them is burned, so cellulosic ethanol fuel has the potential to have a lower carbon footprint than fossil fuels.

A biorefinery is a refinery that converts biomass to energy and other beneficial byproducts. The International Energy Agency Bioenergy Task 42 defined biorefining as "the sustainable processing of biomass into a spectrum of bio-based products and bioenergy ". As refineries, biorefineries can provide multiple chemicals by fractioning an initial raw material (biomass) into multiple intermediates that can be further converted into value-added products. Each refining phase is also referred to as a "cascading phase". The use of biomass as feedstock can provide a benefit by reducing the impacts on the environment, as lower pollutants emissions and reduction in the emissions of hazard products. In addition, biorefineries are intended to achieve the following goals:

- Supply the current fuels and chemical building blocks

- Supply new building blocks for the production of novel materials with disruptive characteristics

- Creation of new jobs, including rural areas

- Valorization of waste

- Achieve the ultimate goal of reducing GHG emissions

Algaculture is a form of aquaculture involving the farming of species of algae.

A photobioreactor (PBR) refers to any cultivation system designed for growing photoautotrophic organisms using artificial light sources or solar light to facilitate photosynthesis. PBRs are typically used to cultivate microalgae, cyanobacteria, and some mosses. PBRs can be open systems, such as raceway ponds, which rely upon natural sources of light and carbon dioxide. Closed PBRs are flexible systems that can be controlled to the physiological requirements of the cultured organism, resulting in optimal growth rates and purity levels. PBRs are typically used for the cultivation of bioactive compounds for biofuels, pharmaceuticals, and other industrial uses.

Biobased economy, bioeconomy or biotechonomy is economic activity involving the use of biotechnology and biomass in the production of goods, services, or energy. The terms are widely used by regional development agencies, national and international organizations, and biotechnology companies. They are closely linked to the evolution of the biotechnology industry and the capacity to study, understand, and manipulate genetic material that has been possible due to scientific research and technological development. This includes the application of scientific and technological developments to agriculture, health, chemical, and energy industries.

Algae fuel, algal biofuel, or algal oil is an alternative to liquid fossil fuels that uses algae as its source of energy-rich oils. Also, algae fuels are an alternative to commonly known biofuel sources, such as corn and sugarcane. When made from seaweed (macroalgae) it can be known as seaweed fuel or seaweed oil.

Biogasoline, or biopetrol, is a type of gasoline produced from biomass such as algae. Like traditionally produced gasoline, it is made up of hydrocarbons with 6 (hexane) to 12 (dodecane) carbon atoms per molecule and can be used in internal combustion engines. Biogasoline is chemically different from biobutanol and bioethanol, as these are alcohols, not hydrocarbons.

Cellana, Inc. is an American company which develops of algae-based bioproducts for high-value nutrition, ink, and bioenergy applications, including Omega-3 nutraceutical applications, sustainable ink, aquaculture and animal feeds, human food ingredients, pigments, specialty chemicals, and biofuels. The company, with offices in Hawaii and San Diego, has received multiple multimillion-dollar grants from the United States Department of Energy and United States Department of Agriculture.

Algenol, founded in 2009, headquartered in Fort Myers, Florida, Algenol is an industrial biotechnology company that is commercializing patented algae technology for production of ethanol and other fuels. The technology enables production four of the most important fuels using a proprietary process involving algae, sunlight, carbon dioxide and salt water.

An algae bioreactor is used for cultivating micro or macro algae. Algae may be cultivated for the purposes of biomass production (as in a seaweed cultivator), wastewater treatment, CO2 fixation, or aquarium/pond filtration in the form of an algae scrubber. Algae bioreactors vary widely in design, falling broadly into two categories: open reactors and enclosed reactors. Open reactors are exposed to the atmosphere while enclosed reactors, also commonly called photobioreactors, are isolated to varying extents from the atmosphere. Specifically, algae bioreactors can be used to produce fuels such as biodiesel and bioethanol, to generate animal feed, or to reduce pollutants such as NOx and CO2 in flue gases of power plants. Fundamentally, this kind of bioreactor is based on the photosynthetic reaction, which is performed by the chlorophyll-containing algae itself using dissolved carbon dioxide and sunlight. The carbon dioxide is dispersed into the reactor fluid to make it accessible to the algae. The bioreactor has to be made out of transparent material.

Bioproducts or bio-based products are materials, chemicals and energy derived from renewable biological material.

Dr. George Philippidis is a renewable energy and sustainability leader, who has published and spoken extensively about the global need for renewable energy as the foundation of a green economy and a sustainable society. He advocates the development of renewable power and fuels to enhance energy security, combat climate change, and secure sustainable economic growth. He has authored 11 cleantech patents, written numerous articles, and spoken nationally and internationally emphasizing that renewable energy can initially supplement and augment current resources and progressively replace fossil energy based on its own merits rather than on government policy.

Nannochloropsis is a genus of alga within the heterokont line of eukaryotes, that is being investigated for biofuel production. One marine Nannochloropsis species has been shown to be suitable for algal biofuel production due to its ease of growth and high oil content, mainly unsaturated fatty acids and a significant percentage of palmitic acid. It also contains enough unsaturated fatty acid linolenic acid and polyunsaturated acid for a quality biodiesel.

Microalgae or microscopic algae grow in either marine or freshwater systems. They are primary producers in the oceans that convert water and carbon dioxide to biomass and oxygen in the presence of sunlight.

Culture Biosystems, originally known as Culture Fuels, Inc., is a privately owned renewable energy company in the United States. Its technology provides a cultivation platform for large-scale production of algae for conversion into diesel and aviation fuel. Its products provide a hybrid algae cultivation system alternative to open ponds and closed photobioreactors.

Cellulosic sugars are derived from non-food biomass (e.g. wood, agricultural residues, municipal solid waste). The biomass is primarily composed of carbohydrate polymers cellulose, hemicellulose, and an aromatic polymer (lignin). The hemicellulose is a polymer of mainly five-carbon sugars C5H10O5 (xylose). and the cellulose is a polymer of six-carbon sugar C6H12O6 (glucose). Cellulose fibers are considered to be a plant’s structural building blocks and are tightly bound to lignin, but the biomass can be deconstructed using Acid hydrolysis, enzymatic hydrolysis, organosolv dissolution, autohydrolysis or supercritical hydrolysis. A more recent mechanical method offers hope that at last, a more economic and waste free method has been found although it is still to scale and is not yet commercial.

Chlorella vulgaris is a species of green microalga in the division Chlorophyta. It is mainly used as a dietary supplement or protein-rich food additive in Japan.

References

- ↑ René H. Wijffels, Maria J. Barbosa. An Outlook on Microalgal Biofuels. Science, 2010; 329 (5993): 796 doi : 10.1126/science.1189003